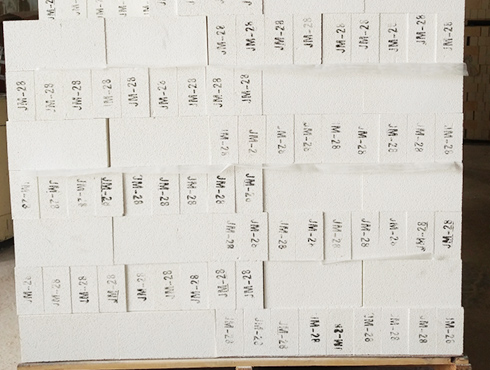

Mullite Insulation Brick

- Al2O3(%)≥: 42-72

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.6-1.1

- Cold Crushing Strength (MPa)≥: 1.5-3.5

- Standard Size: 230*114*65mm

- Certification: ISO9001/ISO14001/ISO45001/ISO50001

- Sample: testing of sample is available

Description of Mullite Insulation Brick

Mullite insulation brick is also called mullite lightweight brick, and it is a refractory material based on aluminum silicate. The alumina fluctuates between 40% and 77%, which has excellent thermal insulation performance. Mullite thermal insulation bricks contain mullite ore, which is made through high-temperature expansion treatment to cast bricks with light weight and excellent thermal insulation performance. In addition to mullite, mullite bricks with low alumina content also contain glass phase and cristobalite; those with high alumina content also contain a small amount of corundum. It can directly touch the flame, the bulk density is 0.55-1.35g/cm3, and the compressive strength is 1.2-4.5Mpa.

Kerui Mullite Insulation Brick Technical Data Sheet

| Item/Grade | JM-23 | JM-26 | JM-28 | JM-30 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ω (Al2O3)/% | 42 | 45 | 48 | 54 | 55 | 56 | 56 | 64 | 65 | 66 | 72 | 72 |

| ω (Fe2O3)/% | 1.2 | 1.0 | 1.0 | 0.9 | 0.8 | 1.0 | 1.0 | 0.75 | 0.65 | 0.65 | 0.55 | 0.55 |

| Bulk Density (g/cm³) | 0.6 | 0.8 | 1.0 | 0.7 | 0.8 | 0.9 | 1.0 | 0.8 | 0.8 | 1.0 | 1.0 | 1.1 |

| Cold Crushing Strength/MPa | 1.5 | 2.3 | 3.0 | 2.0 | 2.3 | 2.8 | 3.2 | 2.3 | 2.8 | 3.3 | 3.0 | 3.5 |

| Permanent Linear Change/% | -0.55 | -0.4 | -0.3 | -1.0 | -0.65 | -0.5 | -0.5 | -1.0 | -0.8 | -0.7 | -0.9 | -0.7 |

| 1260℃×12h | 1300℃×12h | 1300℃×12h | 1400℃×12h | 1400℃×12h | 1400℃×12h | 1400℃×12h | 1500℃×12h | 1500℃×12h | 1500℃×12h | 1600℃×12h | 1600℃×12h | |

| Thermal Conductivity 350℃ ≤/[W/(m·K)] | 0.19 | 0.24 | 0.31 | 0.21 | 0.25 | 0.30 | 0.32 | 0.28 | 0.32 | 0.34 | 0.40 | 0.43 |

Advantages of Mullite Insulation Brick

Excellent Insulation Properties

Mullite insulation bricks are well known for their insulating properties due to their low thermal conductivity which prevents heat from being lost, which makes it an ideal insulating material to provide insulation in high temperatures.

Lightweight Material

The performance of mullite bricks in reducing the atmosphere is very stable. In particular, the calcium element it contains makes it resistant to corrosion and works stably for a long time at high temperatures.

Thermal Shock Resistance

The excellent thermal shock resistance of Mullite Insulation Brick enables them to withstand the heat shock of rejection. Whether it is a sudden increase or decrease in temperature, Mullite Insulation Bricks can maintain their own integrity without cracking and damage. This excellent performance makes it very suitable for industrial furnaces in high temperature environments, etc.

Corrosion Resistance

Although mullite insulation bricks are light in weight, they have a stable structure, can withstand a lot of pressure, and have excellent compressive strength.

Manufacturing Process of Mullite Insulation Brick

Prepare Raw Materials

Prepare a certain amount of high alumina bauxite and composite refractory clay containing Al2O3 as raw materials, and add additives. Such as silica fume, kaolin, aluminum silicate, etc. These additives can improve the fire resistance, stability, and thermal stability of bricks.

Molding

Grind and mix the above prepared raw materials, and put the mixed material into the mold, and shape it by pressing. At the same time, a certain amount of wet binder can be added to improve the plasticity of the brick, which can make the powder particles have a strong binding force during the molding process.

Drying

Drying is putting the formed bricks neatly in the drying equipment or kiln to remove excess moisture in the bricks. The drying process often goes through several stages, the first is initial drying, usually at a lower temperature, which can drain the moisture on the brick surface, just by natural wind. Afterward, heating and drying, as the temperature of the equipment gradually increases, promotes the evaporation of moisture inside the brick body but avoids excessive drying and damage to the rotation body. After the drying time, the device can be used to detect whether it is completely dry.

Sintering

The dried bricks are heated and calcined in a high-temperature kiln. The temperature is 1380℃. During the sintering process, the alumina in the raw materials begins to melt and react with other components. Particles bond stronger to form a complete and compact brick.

Cooling

Cooling is the last step in the production process of high alumina insulation bricks. After the calcination is completed, the temperature of the bricks is gradually lowered to room temperature.

Application of Mullite Insulation Brick

Glass Industry

Mullite Insulation Brick are often used in glass furnace linings, glass quenching linings, glass melting furnace linings, glass crucibles, etc. They can provide excellent fire resistance, heat preservation, and slag resistance, ensuring glass production Process stability, efficiency, and quality.

Ceramic Industry

Mullite Insulation Brick usually used in the lining of the ceramic kiln, the lining of ceramic drying furnaces, the lining of sintering furnaces, and the application of high alumina insulation brick can provide thermal insulation performance and thermal insulation effect.

Iron and Steel Industry

Mullite Insulation Brick usually used in blast furnace lining, hot blast stove lining, ladle lining, furnace roof, etc., which can improve the safety of the working environment and improve production efficiency.

Petrochemical Industry

Mullite Insulation Brick often used in gas furnace equipment, furnace lining, heat exchange equipment, etc. High alumina insulation bricks can prolong the life of petrochemical equipment and keep the temperature stable.