Ceramic Fiber Board

- Modules of Rupture ≥/MPa: 0.3

- Bulk Density (g/cm³): 250-360

- Classification Temperature (℃): 1260-1430

- Loss of Ignition ≤/%: 6

- Certification: ISO9001/ISO14001/ISO45001/ISO50001

- Sample: testing of sample is available

Description of Ceramic Fiber Board

Ceramic fiber board is a kind of refractory material, usually composed of alumina and silicate, and it is also called an aluminum silicate board. Ceramic fiber board is made of ceramic fiber cotton, natural refractory raw materials, and a small amount of organic binder as the main raw materials, and is processed by a fully automated control continuous production line. After heating, it has very good mechanical properties and has a certain hardness support, which provides a strong guarantee for the kiln to save energy and reduce consumption, high quality, and high output.

Kerui Ceramic Fiber Board Technical Data Sheet

| Item/Grade | STD Board | HP Board | HA Board | HZ Board | |

|---|---|---|---|---|---|

| Classification Temperature/℃ | 1260 | 1260 | 1350 | 1430 | |

| Color | White | White | White | White | |

| Bulk Density (kg/m³) | 250/300/360 | 250/300/360 | 300/360 | 300/360 | |

| Modules of Rupture ≥/MPa | 0.3 | 0.3 | 0.3 | 0.3 | |

| Compressive Strength/MPa (10% relative deformation) | 0.15/0.25/0.3 | 0.25/0.3 | 0.25/0.3 | 0.25/0.3 | |

| Loss of Ignition ≤/% | 6 | 6 | 6 | 6 | |

| Permanent Linear Change ≤/% | 1000℃ x 24h 3.0 | 1100℃ x 24h 3.0 | 1200℃ x 24h 3.0 | 1350℃ x 24h 3.0 |

|

| Thermal Conductivity Coefficient /[W/(m·K)] | 400℃ | 0.08 | 0.07 | 0.07 | 0.07 |

| 600℃ | 0.11 | 0.1 | 0.1 | 0.09 | |

| 800℃ | 0.14 | 0.14 | 0.13 | 0.13 | |

| 1000℃ | 0.19 | 0.19 | 0.19 | 0.18 | |

Advantages of Ceramic Fiber Board

Lightweight

Ceramic fiberboard has low density, easy to handle, and has high strength. This makes it easier and more flexible in various applications and reduces the load on the structure. Kerui Refractory will provide you with the highest quality ceramic fiber boards.

Evenly Heated

Uniform fiber distribution ensures evenly surface heating temperature and reduces thermal strain. This helps avoid cracking and deformation caused by temperature differences, improving product stability and durability.

Good Toughness

Ceramic fiberboard has a certain tensile capacity and is not easy to break. This enables resistance to impact and mechanical stress during use, enhancing the durability of the product. Welcome to visit Kerui Factory.

High Compressive Strength

It can withstand a certain amount of pressure and maintain structural integrity and stability. Ceramic fiber board ensures the reliability and safety of the product during use. It has a long service life.

Manufacturing process of Ceramic Fiber Board

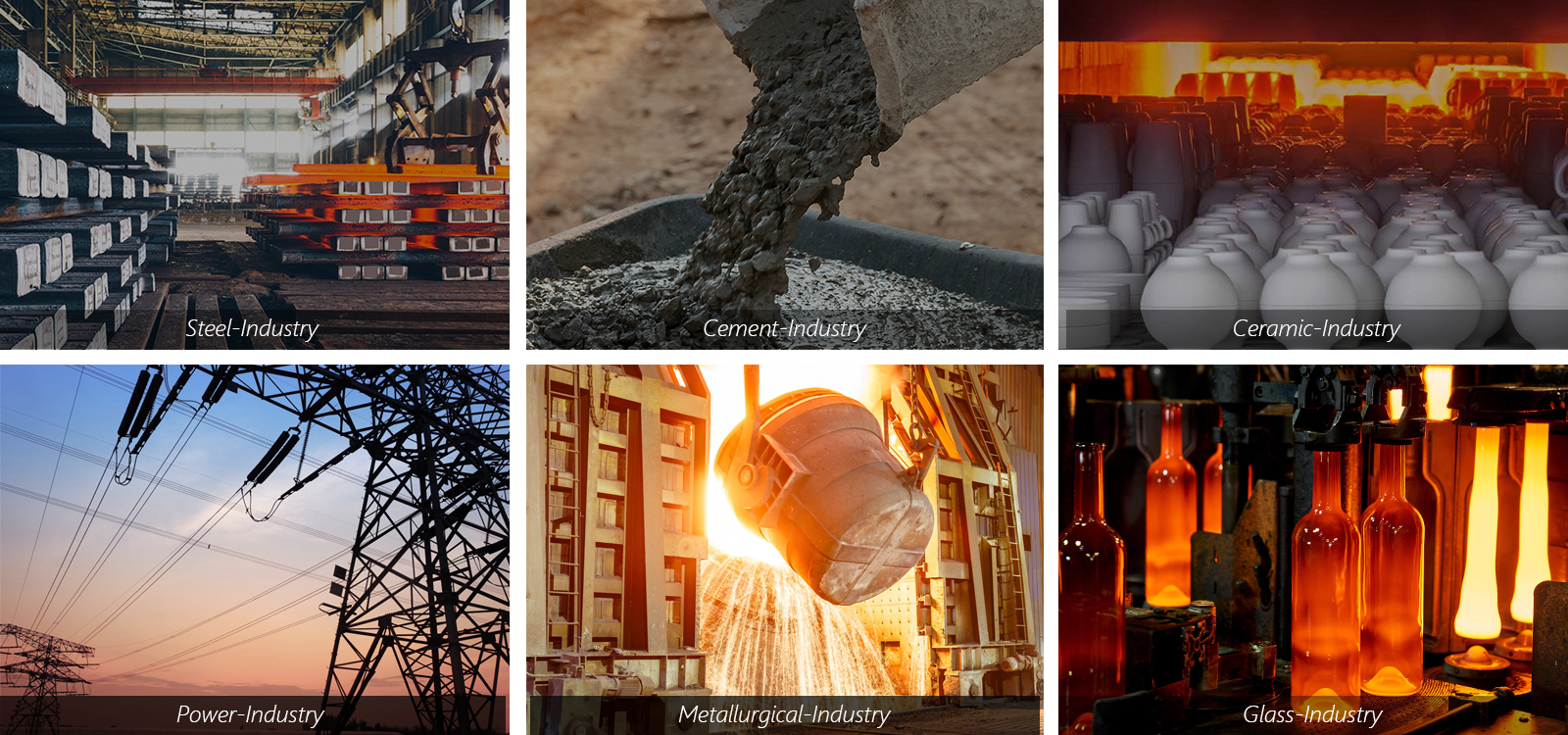

Application of Ceramic Fiber Board

Metallurgical Industry

Ceramic fiber boards can be used for heat insulation and insulation layers of high-temperature equipment such as blast furnaces, ironmaking furnaces, steel furnaces, aluminum electrolytic cells, and copper electrolytic cells.

Petrochemical Industry

Layered ceramic fiber lining structure; stacked (folding) modular structure lining; veneer ceramic fiber lining structure; amorphous ceramic fiber lining structure; composite structure lining structure.

Power Industry

Ceramic fiber boards can be used for thermal insulation of thermal power plant boilers, chimneys, pipes and other electrical insulation materials and high-temperature equipment. Welcome to visit Kerui factory.

Electronics Industry

Ceramic fiberboard can be used in the insulation zone of high-temperature furnaces and other equipment in the manufacture of electronic components. Best Ceramic Fiber Board in Kerui Refractory.

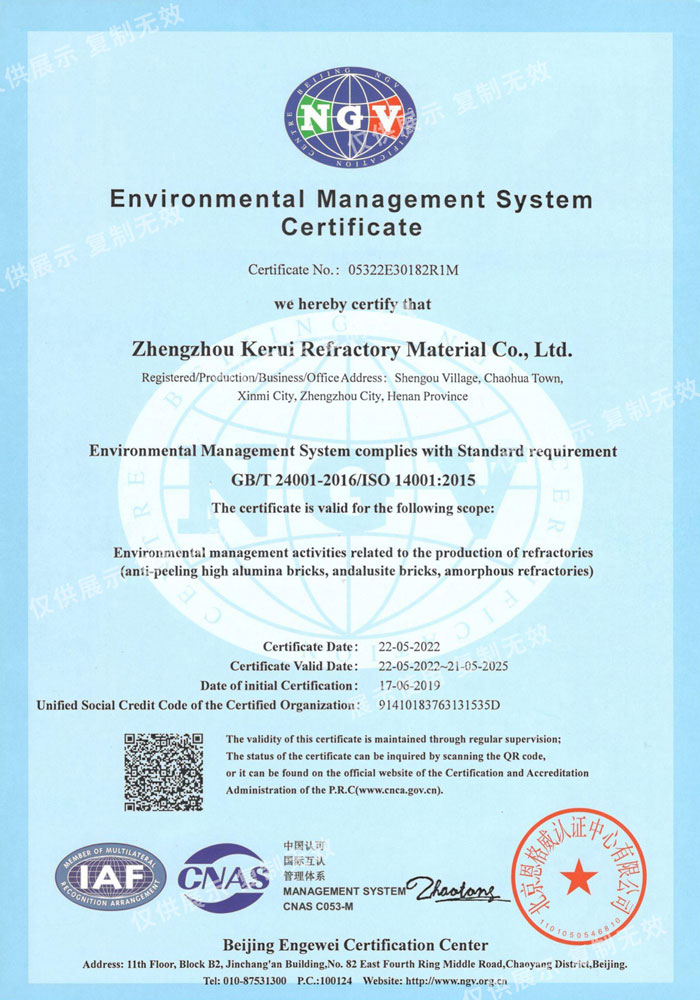

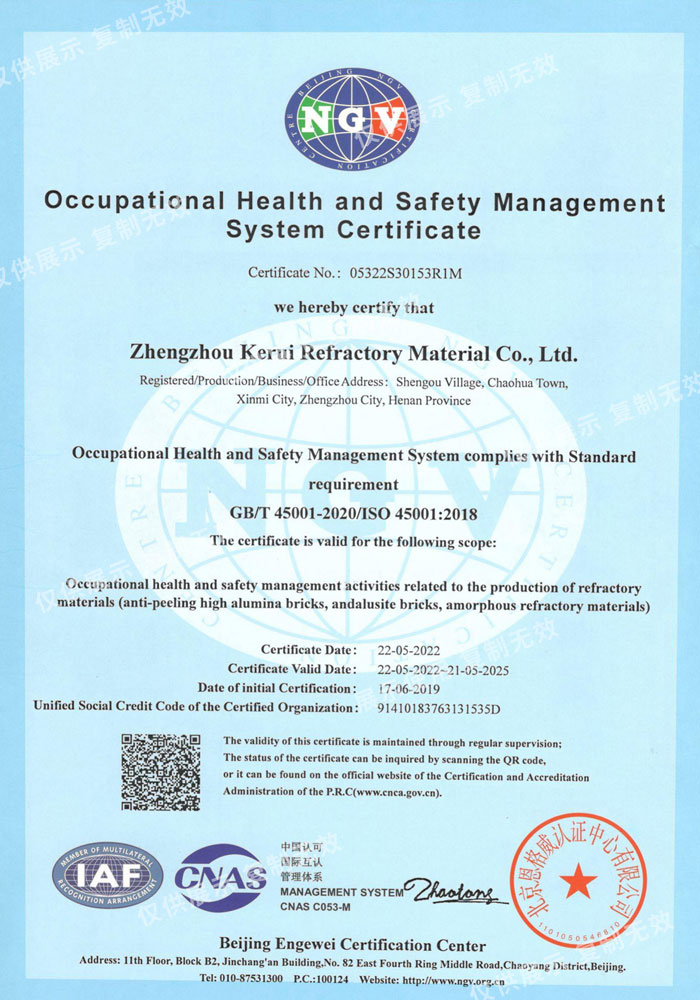

CERTIFICATES OF KERUI REFRACTORY

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

Laboratory of Kerui Refractory

Kerui has a professional quality inspection laboratory. High temperature reheating/load softening creep test furnace;Compressive/flexural strength testing bench for refractory materials; Composition testing and inspection platform for refractory materials; Laboratory for physical/chemical properties for refractory materials.

KERUI REFRACTORY PRDUCTS PACKAGING&SHIPPING

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism. If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

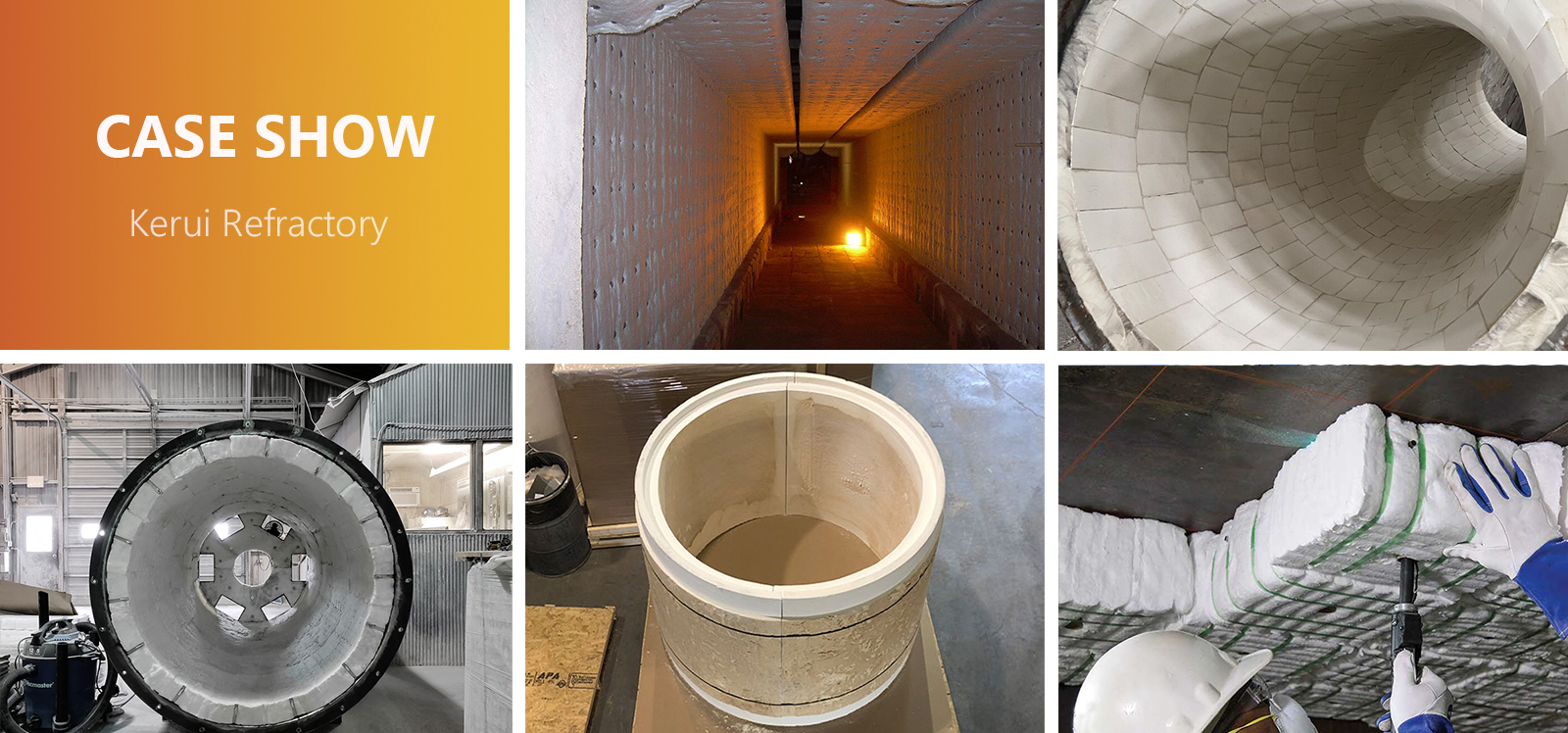

CUSTOMER CASE OF KERUI REFRACTORY

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania. We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ return orders and referrals.