Magnesia Carbon Brick

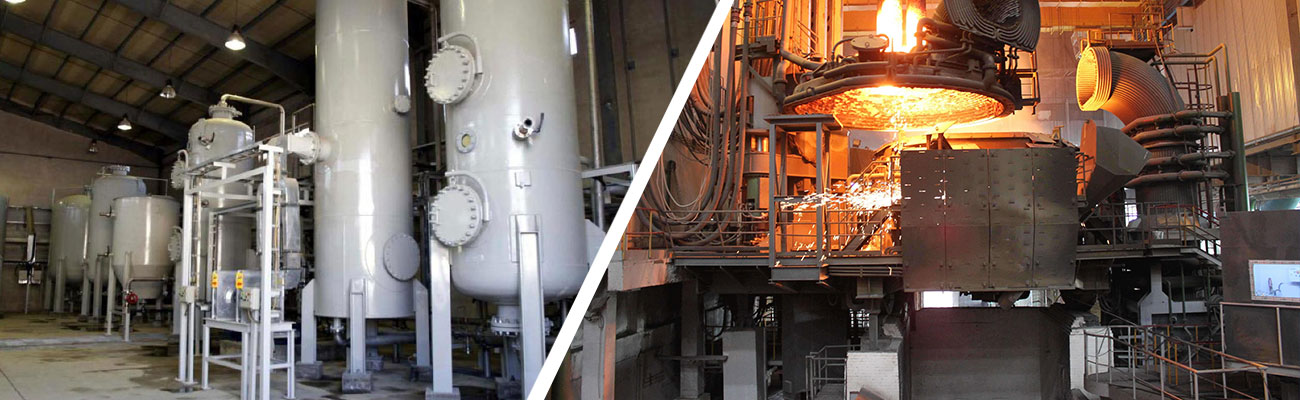

Magnesia carbon bricks are mainly used in the lining of converters, AC electric arc furnaces, DC electric arc furnaces, and slag lines of ladles in the steelmaking industry.

- MgO%: 69-85

- C%: 5-18

- Bulk Density (g/cm³): 2.79-3.05

- Cold Crushing Strength (MPa): 30-50

- Standard Size: 230*114*65mm

- Sample: testing of sample is available

Description of Magnesia Carbon Brick

Magnesia carbon brick is a non-burning carbon composite refractory material combined with carbon binder. Using high melting point basic oxide magnesium oxide (melting point 2800°C) and high melting point carbon material which is difficult to be infiltrated by slag as raw materials, various non-oxide additives are added. As a composite refractory material, magnesia carbon brick effectively utilizes the strong slag erosion resistance of magnesia and the high thermal conductivity and low expansion of carbon to compensate for the biggest shortcoming of magnesia’s poor spalling resistance.

Kerui Magnesia Carbon Brick Technical Data Sheet

| Item/Grade | Apparent Porosity/% | Bulk Density (g/cm³) | Cold Crushing Strength/MPa | High-temperature Bending Strength (1400℃*0.5h)/MPa | ω (MgO)/% | ω (C)/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| μ0 ≤ | σ | μ0 ≥ | σ | μ0 | σ | μ0 ≥ | σ | μ0 ≥ | σ | μ0 ≥ | σ | |

| MT-5A | 5.0 | 1.0 | 3.10 | 0.05 | 50.0 | 10.0 | / | / | 85.0 | 1.5 | 5.0 | 1.0 |

| MT-5B | 6.0 | 1.0 | 3.02 | 0.05 | 50.0 | 10.0 | / | / | 84.0 | 1.5 | 5.0 | 1.0 |

| MT-5C | 7.0 | 1.0 | 2.92 | 0.05 | 45.0 | 10.0 | / | / | 82.0 | 1.5 | 5.0 | 1.0 |

| MT-5D | 8.0 | 1.0 | 2.90 | 0.05 | 40.0 | 10.0 | / | / | 80.0 | 1.5 | 5.0 | 1.0 |

| MT-8A | 4.5 | 1.0 | 3.05 | 0.05 | 45.0 | 10.0 | / | / | 82.0 | 1.5 | 8.0 | 1.0 |

| MT-8B | 5.0 | 1.0 | 3.00 | 0.05 | 45.0 | 10.0 | / | / | 81.0 | 1.5 | 8.0 | 1.0 |

| MT-8C | 6.0 | 1.0 | 2.90 | 0.05 | 40.0 | 10.0 | / | / | 79.0 | 1.5 | 8.0 | 1.0 |

| MT-8D | 7.0 | 1.0 | 2.87 | 0.05 | 35.0 | 10.0 | / | / | 77.0 | 1.5 | 8.0 | 1.0 |

| MT-10A | 4.0 | 0.5 | 3.02 | 0.03 | 40.0 | 10.0 | 6.0 | 1.0 | 80.0 | 1.5 | 10.0 | 1.0 |

| MT-10B | 4.5 | 0.5 | 2.97 | 0.03 | 40.0 | 10.0 | / | / | 79.0 | 1.5 | 10.0 | 1.0 |

| MT-10C | 5.0 | 0.5 | 2.92 | 0.03 | 35.0 | 10.0 | / | / | 77.0 | 1.5 | 10.0 | 1.0 |

| MT-10D | 6.0 | 0.5 | 2.87 | 0.03 | 35.0 | 10.0 | / | / | 75.0 | 1.5 | 10.0 | 1.0 |

| MT-12A | 4.0 | 0.5 | 2.97 | 0.03 | 40.0 | 10.0 | 6.0 | 1.0 | 78.0 | 1.2 | 12.0 | 1.0 |

| MT-12B | 4.0 | 0.5 | 2.94 | 0.03 | 35.0 | 10.0 | / | / | 77.0 | 1.2 | 12.0 | 1.0 |

| MT-12C | 4.5 | 0.5 | 2.92 | 0.03 | 35.0 | 10.0 | / | / | 75.0 | 1.2 | 12.0 | 1.0 |

| MT-12D | 5.5 | 0.5 | 2.85 | 0.03 | 30.0 | 10.0 | / | / | 73.0 | 1.2 | 12.0 | 1.0 |

| MT-14A | 3.5 | 0.5 | 2.95 | 0.03 | 38.0 | 10.0 | 10.0 | 1.0 | 76.0 | 1.2 | 14.0 | 1.0 |

| MT-14B | 3.5 | 0.5 | 2.90 | 0.03 | 35.0 | 10.0 | / | / | 74.0 | 1.2 | 14.0 | 1.0 |

| MT-14C | 4.0 | 0.5 | 2.87 | 0.03 | 35.0 | 10.0 | / | / | 72.0 | 1.2 | 14.0 | 1.0 |

| MT-14D | 5.0 | 0.5 | 2.81 | 0.03 | 30.0 | 10.0 | / | / | 68.0 | 1.2 | 14.0 | 1.0 |

| MT-16A | 3.5 | 0.5 | 2.92 | 0.03 | 35.0 | 8.0 | 8.0 | 1.0 | 74.0 | 1.2 | 16.0 | 0.8 |

| MT-16B | 3.5 | 0.5 | 2.87 | 0.03 | 35.0 | 8.0 | / | / | 72.0 | 1.2 | 16.0 | 0.8 |

| MT-16C | 4.0 | 0.5 | 2.82 | 0.03 | 30.0 | 8.0 | / | / | 70.0 | 1.2 | 16.0 | 0.8 |

| MT-18A | 3.0 | 0.5 | 2.89 | 0.03 | 35.0 | 8.0 | 10.0 | 1.0 | 72.0 | 1.2 | 18.0 | 0.8 |

| MT-18B | 3.5 | 0.5 | 2.84 | 0.03 | 30.0 | 8.0 | / | / | 70.0 | 1.2 | 18.0 | 0.8 |

| MT-18C | 4.0 | 0.5 | 2.79 | 0.03 | 30.0 | 8.0 | / | / | 69.0 | 1.2 | 18.0 | 0.8 |

Advantages of Magnesia Carbon Brick

Excellent High Temperature Resistance

Magnesia carbon bricks have excellent high temperature performance and can be used for a long time above 1200 °C.

Corrosion Resistance

Magnesia carbon bricks have excellent corrosion resistance, so they can be used in strong corrosive environments such as acids and alkalis.

Good Thermal Shock Resistance

Magnesia carbon bricks have very good thermal shock performance at high temperatures, and can withstand large temperature gradient changes without cracking.

Good Thermal Conductivity

Magnesia-carbon bricks have good thermal conductivity, which can evenly distribute and transfer heat, which is conducive to improving production efficiency.

Manufacturing Process and Advantages Of Magnesia Carbon Brick

Excellent Electrical Conductivity

As a conductive refractory material, magnesia carbon brick has excellent electrical conductivity and can be used as an electrode material.

High Corrosion Resistance

Magnesia carbon bricks still have good corrosion resistance in strong corrosive environments such as acid and alkali.

Strong Oxidation Resistance

Magnesia carbon bricks have very strong oxidation resistance, can resist oxidation in the air, and have very good long-term durability.

Good Environmental Protection

The production process of magnesia carbon brick has no pollution, no waste water and no waste gas discharge, so it is an environmentally friendly refractory material.

Application of Magnesia Carbon Brick

Iron and Steel Smelting

Magnesia carbon bricks are widely used in various equipment in the iron and steel smelting industry, such as converters, electric arc furnaces, steelmaking tanks, etc. They are used as lining materials and are able to withstand the high temperatures and corrosion of the molten metal produced during the smelting process.

Aluminum Smelting

Magnesia carbon bricks are also used in electrolytic cells in the aluminum smelting industry. The electrolytic cell is the main equipment for aluminum electrolysis, and the magnesia carbon brick shows good fire resistance and electrical conductivity in the electrolytic cell.

Ladle Repair

In ladle maintenance and repair, magnesia carbon bricks are often used to repair the refractory lining of the bottom and side walls of the ladle. This prolongs the service life of the ladle and ensures the quality of the molten steel.

High Temperature Industrial Furnaces

Magnesia-carbon bricks are suitable for various high-temperature industrial furnaces, such as oil refining furnaces, chemical furnaces, glass melting furnaces, etc. They are able to withstand high temperature environments, chemical attack and thermal shock stress.

Machinery Manufacturing Industry

Magnesia-carbon bricks can be used to manufacture high-performance electrodes, furnace materials for the semiconductor industry, high-boron alloys, etc.

High-Temperature Reactor

Magnesia-carbon bricks can also be used in high-temperature reactors, such as calciners in the production of aluminum hydroxide and converters in the ammonia synthesis process.