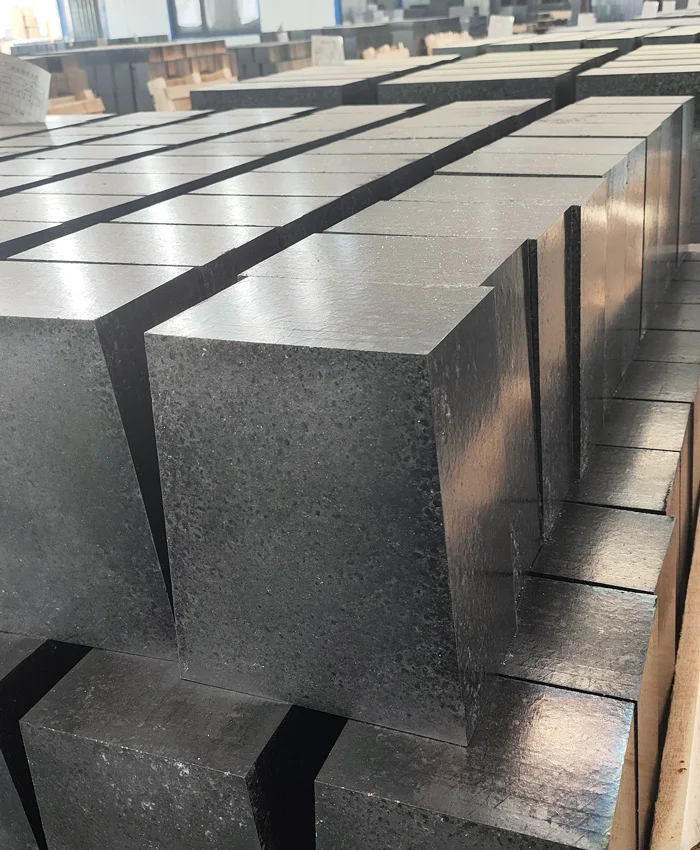

With the rapid development and innovation of Kerui Refractory Company, Kerui Factory has added a fully automated magnesia brick production line, which greatly improves production efficiency, shortens delivery time and can complete delivery to customers in a short time.

Improvement of Kerui’s Production Capacity

With the putting into use of the new magnesia brick production line, the company’s production capacity has been greatly increased, and the annual output value of magnesia bricks has increased to 30,000 tons, which has greatly satisfied the growing market demand and provided a great boost to the development of Kerui.

Environmental Protection and Sustainable Development

Kerui’s new magnesia brick production line uses all environmentally friendly materials, and also saves manpower and material resources to the greatest extent, thus saving energy, and reducing waste, and is conducive to environmental protection and sustainable development. As the largest refractory material manufacturer, Kerui has been actively paying attention to environmental protection issues and promoting sustainable production in society.

In short, the company’s new magnesia brick production line is a move that is beneficial to the company, customers, and society. It can bring more productivity to the company and save costs at the same time; it can greatly shorten the customer’s delivery time and achieve fast delivery; it saves energy, promotes environmental protection, and realizes the significance of sustainable development.