High alumina cement (HAC), also known as calcium aluminate cement, is a specialized hydraulic binder made from alumina-rich raw materials. With an alumina content typically between 40% and 80%, it offers outstanding heat resistance, rapid strength development, and strong durability in corrosive environments. These characteristics make HAC an essential material widely used across modern industrial sectors.

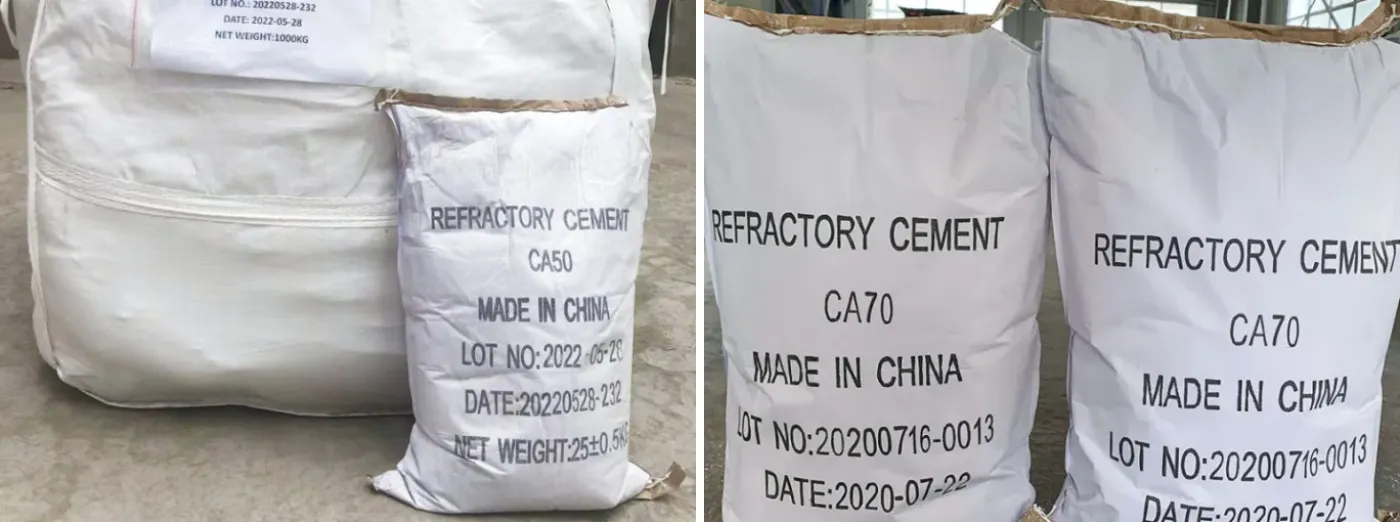

One of the most important applications of high alumina cement is in refractory materia ls. HAC serves as a key binder for castables, gunning mixes, ramming masses, and other monolithic refractories. When combined with refractory aggregates such as bauxite or calcined alumina, HAC-based castables can withstand temperatures above 1500°C. They are commonly used in steelmaking furnaces, rotary kilns, boilers, incinerators, ladles, and power-plant equipment. Its strong thermal-shock resistance helps maintain lining stability during frequent heating and cooling cycles.

ls. HAC serves as a key binder for castables, gunning mixes, ramming masses, and other monolithic refractories. When combined with refractory aggregates such as bauxite or calcined alumina, HAC-based castables can withstand temperatures above 1500°C. They are commonly used in steelmaking furnaces, rotary kilns, boilers, incinerators, ladles, and power-plant equipment. Its strong thermal-shock resistance helps maintain lining stability during frequent heating and cooling cycles.

High alumina cement is also valued for its chemical resistance, particularly against sulfates, acids, alkalis, and industrial fumes. This makes HAC an excellent choice for environments where ordinary Portland cement rapidly deteriorates. It is widely applied in sewage systems, wastewater treatment plants, chemical factories, desalination units, and flue-gas desulfurization facilities. Structures built with HAC maintain long-term durability even under harsh chemical exposure.

Another major advantage of HAC is its rapid setting and early strength. It develops considerable mechanical strength within hours, allowing for fast repairs in tunnels, bridges, ports, railways, and airports. HAC-based repair mortars are especially effective in cold regions where normal cement cures slowly. Its quick hardening properties reduce downtime and restore structural safety efficiently.

In addition, HAC is used for manufacturing heat-resistant construction materials such as fire bricks, refractory tiles, insulation boards, precast shapes, pizza ovens, and chimney linings. The cement ensures safety and stability in applications requiring long-term exposure to high temperatures.

In summary, high alumina cement plays a crucial role in refractory engineering, chemical-resistant construction, rapid structural repair, and high-temperature manufacturing. Its excellent performance under heat, corrosion, and mechanical stress ensures that HAC remains a vital material in modern industrial development.