Refractory Mortar

- Al2O3%: 40-78

- Fe2O3%: 0.7-1.2

- Classification Temperature/℃: 1300-1600

- Refractoriness Underload/℃: 1320-1600

- Certification: ISO9001/ISO14001/ISO45001/ISO50001

- Sample: testing of sample is available

Description of Refractory Mortar

Refractory mortar, also known as high-temperature mortar, can be used to resist high-temperature environments. It is a special type of mortar designed for high-temperature applications where ordinary mortar cannot withstand extreme heat. Refractory mortar is composed of refractory powder, binder, and admixture with a certain particle ratio, poured into water or liquid binder to make a paste. Refractory mortar can be made into powder, and the smallest size can be less than 1mm, and some are even less than 0.5mm. Refractory mortar has high sealing performance and high corrosion resistance. According to different components, it can be divided into clay mortar, high alumina mortar, silicon mortar, magnesia mortar, and so on.

Kerui Refractory Mortar Technical Data Sheet

| Item/Grade | KR-1300 | KR-1400 | KR-1500 | KR-1600 | |

|---|---|---|---|---|---|

| Classification Temperature/℃ | 1300 | 1400 | 1500 | 1600 | |

| Chemical Composition/% | ω (Al2O3)/% | 40 | 53 | 60 | 78 |

| ω (Fe2O3)/% | 1.2 | 1 | 0.9 | 0.7 | |

| Refractoriness Underload/℃ | 1320 | 1410 | 1550 | 1600 | |

Classification of Refractory Mortar

Clay Refractory Mortar

Clay refractory mortar is made of calcined clay together with raw materials and additives. Clinker is the main component of clay refractory mortar, the content is about 75%~80%. As a joint material, clay refractory mortar is mainly used in the joints and repair of furnace bodies built with clay bricks such as blast furnaces, hot blast furnaces, coke ovens, soaking furnaces, heat exchangers, boilers, etc.

Silica Refractory Mortar

Silica refractory mortar is a refractory mortar made of silica powder, clay, admixtures, and binders mixed in a certain particle ratio. Silica mortar has the advantages of acid resistance, high heat resistance, low thermal conductivity, and good bond strength. Silica refractory mortar is mainly used in the masonry and repair of industrial kilns such as hot blast furnaces, coke ovens, and glass furnaces built of silica bricks.

High Alumina Refractory Mortar

High alumina mortar is made of high alumina cement and high alumina aggregate, with alumina content over 60%. The refractoriness is above 1500℃. It is mixed with water to form a paste for laying and bonding shaped refractory products, such as refractory bricks. Our high alumina refractory mortar is the best choice for high temperature fireplaces, ovens, kilns, furnaces and chimney construction.

Advantages of Refractory Mortar

High Bonding Strength

Refractory mortar with water can form a strong bond between refractory bricks or materials when used, which can form a strong and durable structure. It enhances the overall stability and load-bearing capacity of the refractory lining and ensures the integrity of the installation.

High Sealing Performance

High sealing performance means that the mortar will form a tight structure between the refractory bricks or joints to prevent leakage of gases or liquids. This sealing performance is critical for applications that require the containment of combustion gases, molten metals, or other substances.

Excellent Resistance to Slag Erosion

Refractory mortars have excellent resistance to slag erosion. Slag is the residue formed during high-temperature processes such as metal smelting or combustion. The slag resistance of the mortar ensures the longevity and effectiveness of the refractory lining in such environments.

Good Resistance to Spalling

Refractory mortar has good thermal peeling properties. Refractory mortars resist spalling or delamination of refractory bricks or surfaces even under repeated heating and cooling in hot furnaces. This property is essential for maintaining the integrity and stability of the refractory lining over time.

Application of Refractory Mortar

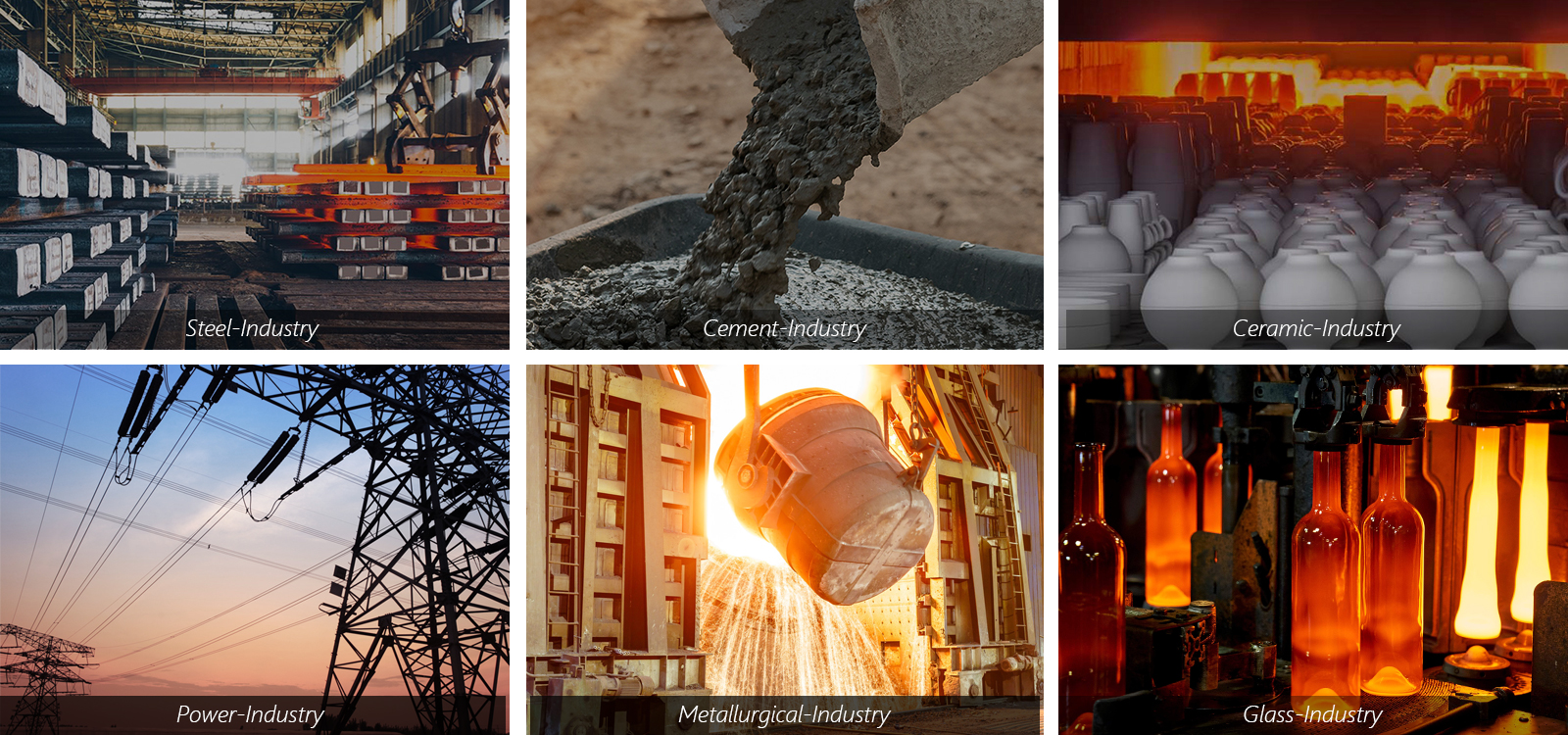

Non-Ferrous Metals Industry

Refractory mortar is used in the non-ferrous metals industry, including the production of aluminum, copper, and zinc. It is used for lining smelters, converters, and other equipment that can withstand high temperatures and corrosive conditions.

Incinerators And Waste Management

Refractory mortar is used in incinerators and waste management facilities for lining combustion chambers and flue systems. It provides thermal insulation and resists the corrosive effects of combustion gases and ashes.

Power Generation

Refractory mortar is used to line boilers, incinerators, and other combustion equipment in power plants. It provides thermal insulation and resists the high temperatures and corrosive gases generated during the power generation process.

Foundry Industry

Refractory mortar is used in foundries for lining crucibles, molds, and other equipment used in metal casting processes. It provides thermal insulation and resistance to molten metal and slag.

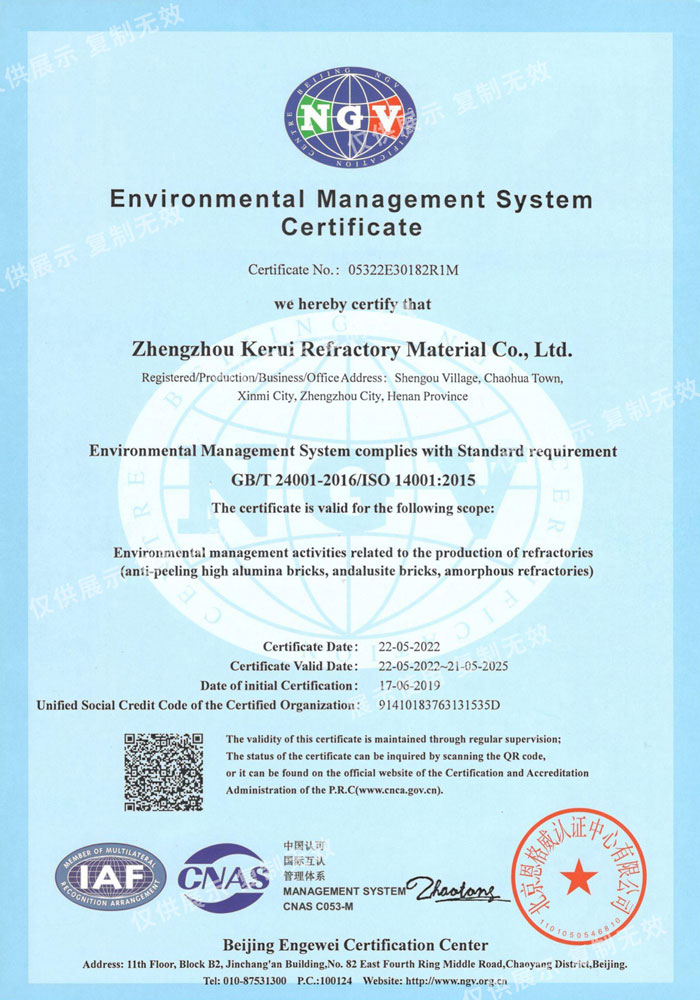

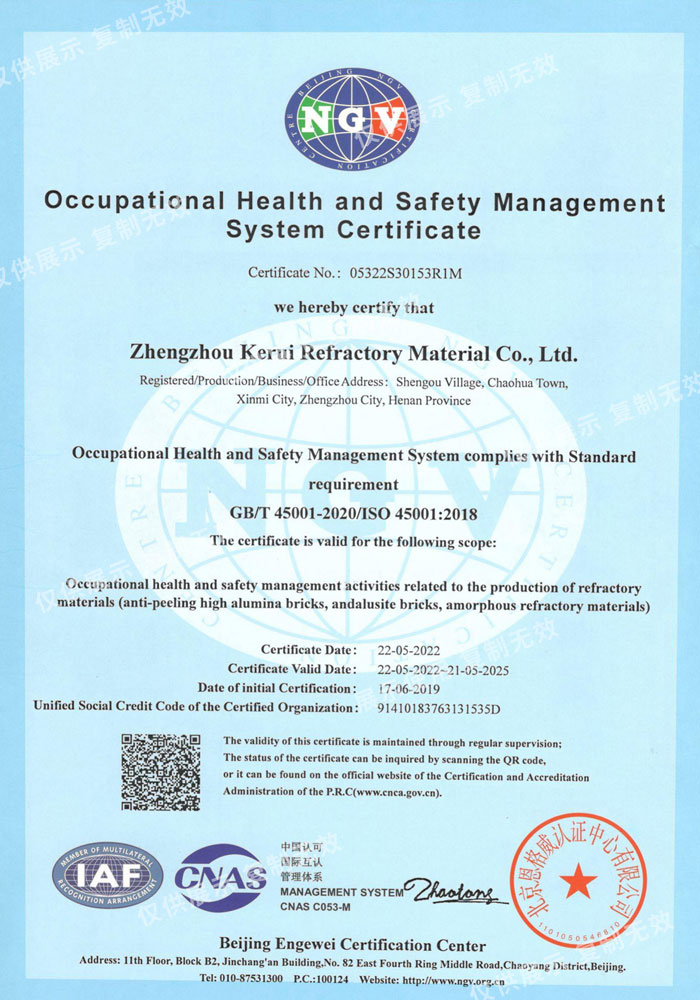

CERTIFICATES OF KERUI REFRACTORY

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

Laboratory of Kerui Refractory

Kerui has a professional quality inspection laboratory. High temperature reheating/load softening creep test furnace;Compressive/flexural strength testing bench for refractory materials; Composition testing and inspection platform for refractory materials; Laboratory for physical/chemical properties for refractory materials.

KERUI REFRACTORY PRDUCTS PACKAGING&SHIPPING

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism. If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

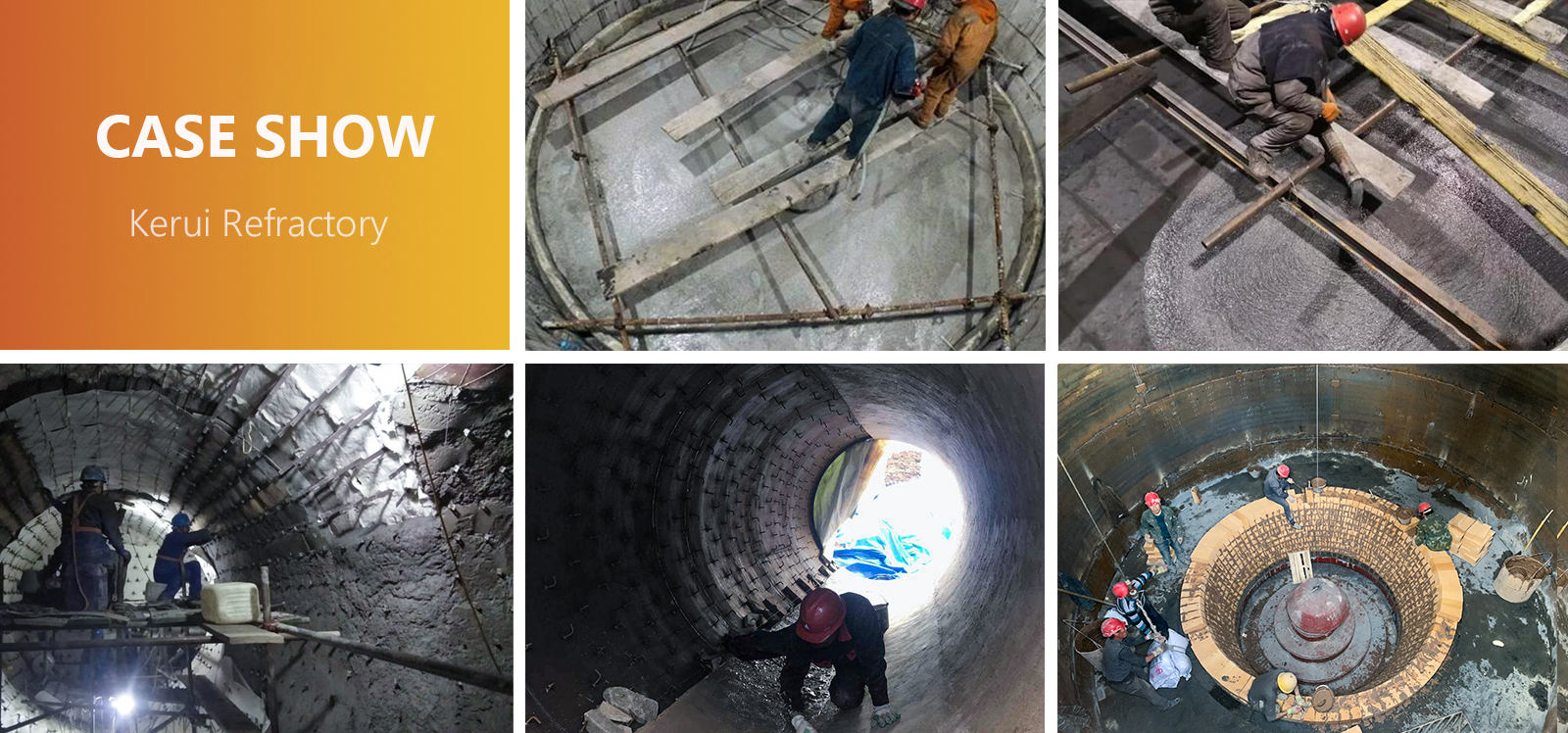

CUSTOMER CASE OF KERUI REFRACTORY

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania. We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ return orders and referrals.