- High Alumina Brick

- Silica Fire Brick

- Corundum Brick

- Fire Clay Brick

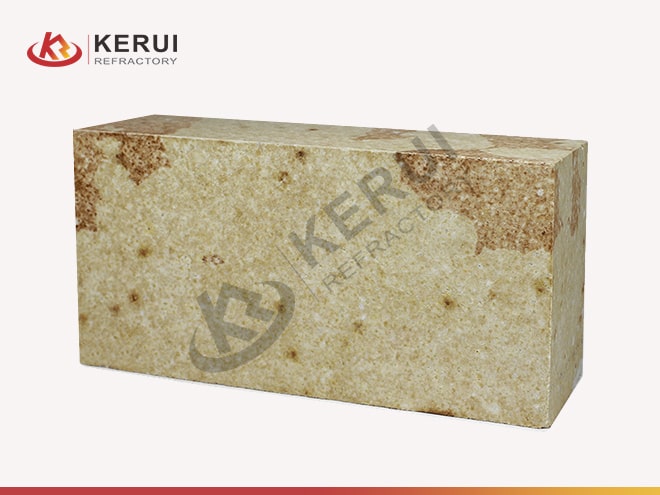

- Al2O3: 55-80%;

- Refractoriness Under Load: 1420-1530℃;

- Cold crushing strength: 40-70MPa;

- Standard Size: 230*114*65mm;

- Color: Yellow;

- Max service temp: 1800℃;

- Al2O3: Max service can up to 95%;

- Sample: available;

- Apparent Porosity, %: ≤26;

- Cold Crushing Strength, MPa: ≥40;

- Price: Low Ex-factory Price;

- Sample: available;

- MgO Chemical composition :≥95 %;

- Apparent Porosity :≤18 %;

- Bulk Density/ (g/cm³): 2.31-2.4

- Bending strength/ (MPa): ≥58.80

- MgO% (≥): 89-97.5

- Bulk Density (g/cm³): 2.85-3.0

- Refractoriness Under Load (℃): 1500-1700

- Size: 230*114*65mm; Customized Sizes

- MgO%: 69-85

- C%: 5-18

- Bulk Density (g/cm³): 2.79-3.05

- Sample: available;

- MgO%(≥): 45-65

- Cr2O3%(≥): 8-16

- Apparent Porosity/%(≤): 19-21

- Cold Crushing Strength (MPa): 20-35

- MgO% ≥:70/75/80 ZrO2 %≥:8/10/13;

- Apparent Porosity%≤:19;

- Bulk Density (g/cm3)≥:2.95;

- Refractoriness Under Load:≥1600 °C

- Al2O3% (≥): 62-70

- Fe2O3)/%(≤): 1.5-1.8

- Refractoriness Under Load (℃)(≥): 1760-1780

- Sample: available;

- Max service temp: 1700℃;

- More than 85% Al2O3 and 0.45% Fe2O3;

- Color: White;

- More than 55MPa cold crushing strength;

- Bulk density g/cm3:≥ 3.15;

- Cold Crushing Strength (Mpa)≥90;

- Apparent Porosity (%):≤17;

- Size: 230*114*65mm; Customized Sizes

- Al2O3:≥30-70%;

- Refractoriness Under Load: 1250-1480ºC;

- Bulk Density: 1.9-2.35g/cm³

- Sample: available;

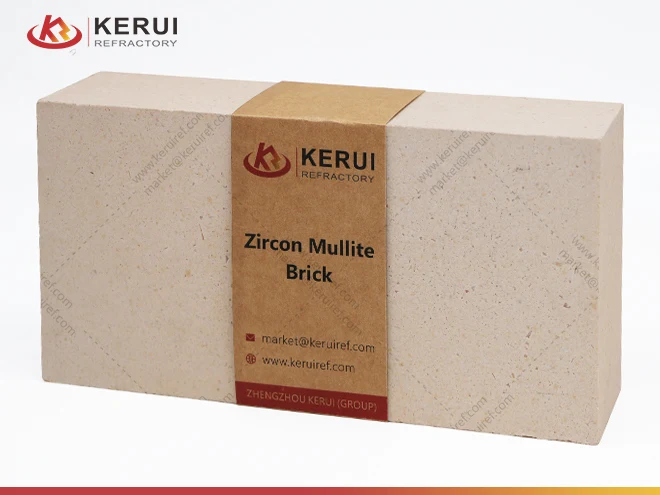

- ZrSiO4: ≥15-65%;

- Bulk Density: 2.7-3.7g/cm³;

- Refractoriness Under Load: 1550-1650ºC;

- Cold Crushing Strength: ≥100MPa;

- ZrO2%: ≥ 16

- Fe2O3%: ≤ 0.5

- Bulk Density (g/cm³): ≥ 2.70

- Cold Crushing Strength/MPa: ≥ 70

- Apparent porosity %: ≤20

- Refractoriness under load°C: ≥1650℃

- Al2O3: ≥45%

- Bulk density g/cm3: ≥3.2

- Bulk density g/cm3:≥ 3.15;

- Cold Crushing Strength (Mpa)≥90;

- Apparent Porosity (%):≤17;

- Size: 230*114*65mm; Customized Sizes

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Bulk Density (g/cm³)(≥): 2.90

- Cold Crushing Strength(≥): 50MPa

- MgO/%(≥): 80

- Al2O3/%(≥): 10

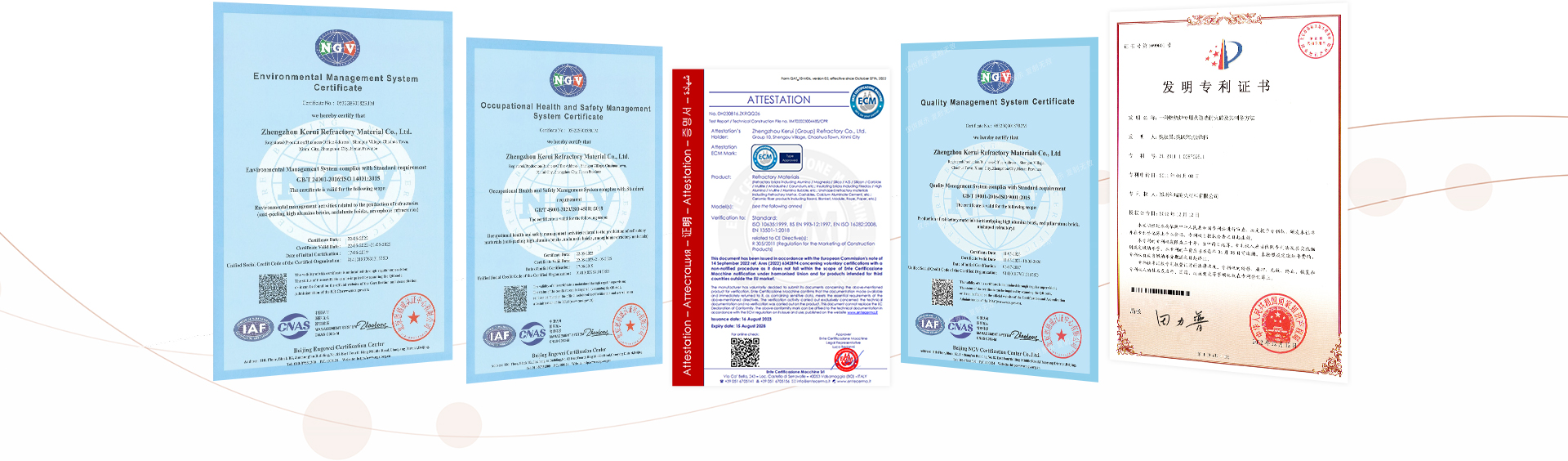

- Certification: ISO9001/ISO14001 /ISO45001/ISO50001

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Bulk Density (g/cm³)(≥): 2.90

- Sample: testing of sample is available

- Al2O3/%: 95-98

- SiO2/%: 0.15-0.5

- Fe2O3/%: 0.1-0.3

- Refractoriness Under Load: 1700MPa

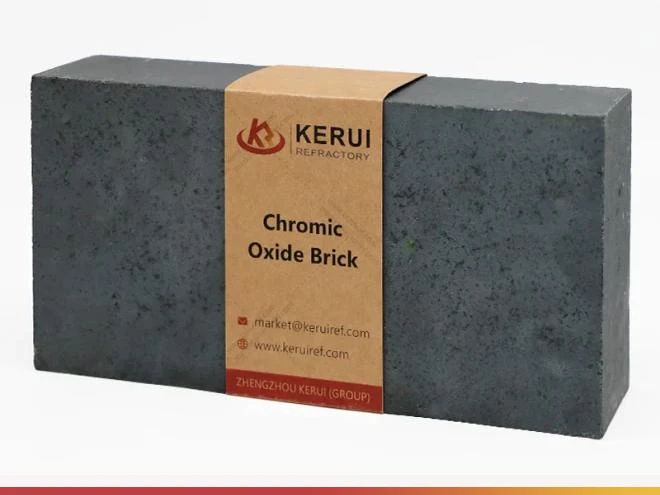

- Cr2O3 %≥:50-93;

- Apparent Porosity %:≤16;

- Bulk Density g/cm3≥:3.5-4.25;

- Load softening temperature, 0.2MPa 0.6%:≥1700;

- Bulk density g/cm3: ≥3.25;

- Apparent Porosity %: ≤15;

- Pressure strength(Mpa)≥1800;

- Load softening temperature(0.2Mpa T0.6 ℃): ≥168;

- Bulk density g/cm3: ≥1.7

- Compressive strength / Mpa: ≥36

- Oxidation rate /%: ≤8

- Average pore size: ≤0.1

- SiO2%: ≥94

- Fe2O3/%: ≤1.4

- True Density (g/cm³): ≤2.35

- Refractoriness Under Load (℃): ≥1650

- Al2O3 ≥/%: 60-65

- Bulk Density: 2.55-2.65g/cm³

- Sample: testing of sample is available

- Cold crushing strength: 85-90MPa

- Al2O3: ≥60-65%;

- SiO2: ≥32-37%;

- Bulk Density: 2.40-2.55g/cm³;

- Cold Crushing Strength: 45-60MPa;

- Magnesia Brick

- Magnesia Spinel Brick

- Magnesia Carbon Brick

- Magnesia Chrome Brick

- Refractoriness: ≥1730-1810℃;

- Al2O3: ≥55-80%;

- Bulk Density: 2.15-2.8g/cm³;

- Sample: available;

- Used for ladles and tundishes;

- Used for rotary kilns;

- Resist heat and chemical corrosion;

- Used for continuous casting process;

- Holes: 7/19/31/37/65/others;

- Delivery: 15-30 Working Days;

- Price: Low Ex-factory Price;

- Sample: available;

- Al2O3 %: >36

- Apparent porosity %: 17-26;

- Bulk Density g/cm3: >2.1;

- Refractoriness ℃: >1700;

- Al2O3(%)≥: 42-72

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.6-1.1

- Cold Crushing Strength (MPa)≥: 1.5-3.5

- MgO+CaO% (≥):92-94;

- CaO% (≥):18-48;

- Apparent Porosity(%):15.0;

- Cold Crushing Strength (MPa):60;

- Acid Resistance ≥/%: 99.8

- Water Absorption ≤/%: 2

- Bulk Density/ (g/cm³): 2.31-2.4

- Bending strength/ (MPa): ≥58.80

- Al2O3(%)≥: 40-77

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.55-1.35

- Cold Crushing Strength (MPa)≥: 0.9-3.5

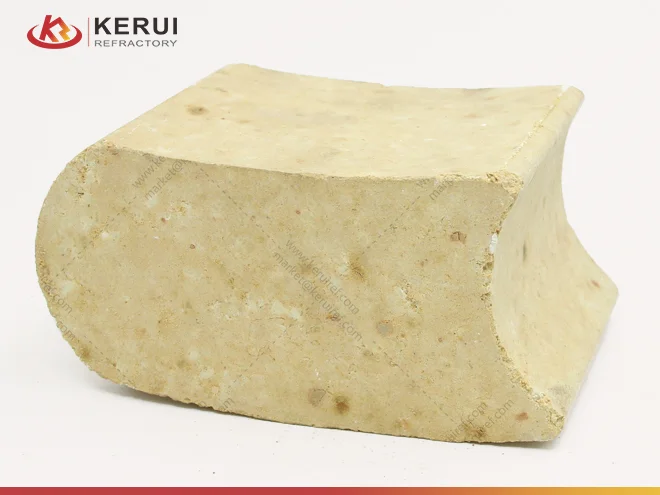

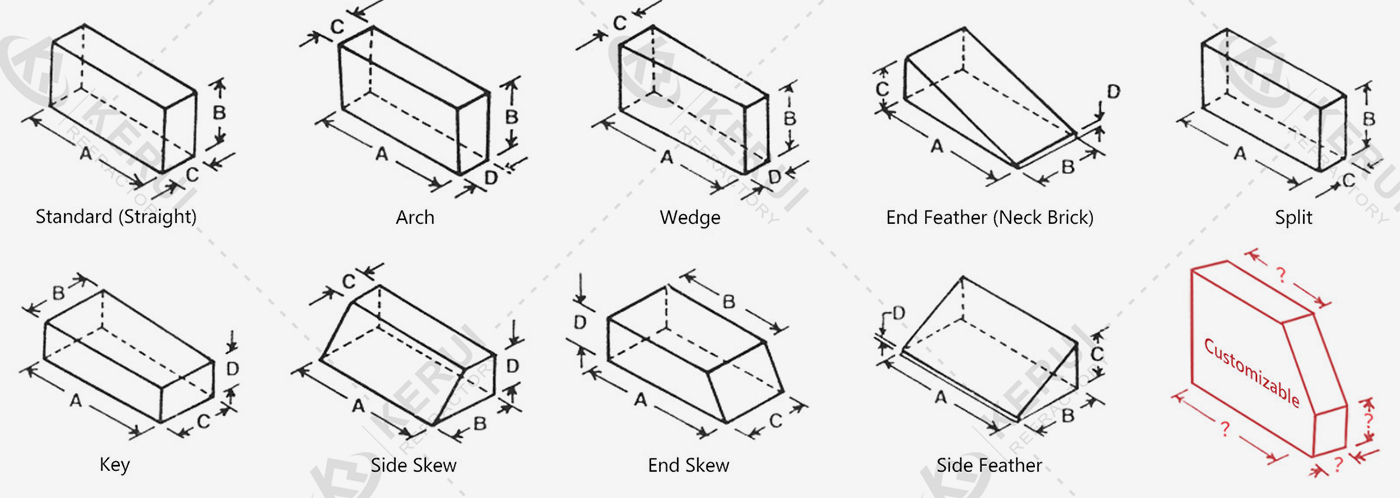

Customized Refractory Fire Bricks

Kerui Refractory factory can be customized all kinds of shaped bricks according to the customer’s request. Because we have own factory, and our own R&D team, technical team, production team. In addition, we also have a professional sales team and service team who are familiar with each market. So welcome to inquiry!

Applications Of Kerui Refractory Fire Bricks

Sintering Furnaces and Kilns

Sintering Furnaces and KilnsRefractory bricks are commonly used in the construction of sintering furnaces and kilns for ceramics, cement, lime, ore and other materials. They are able to withstand high temperatures for long periods of time.

Glass Furnaces

Glass FurnacesIn the glass manufacturing industry, refractory bricks are used to construct glass furnaces that require high temperatures to melt the glass feedstock.

Steel Smelting

Steel SmeltingIn the steel industry, refractory bricks are used to build blast furnaces, converters, electric arc furnaces and other smelting equipment to withstand high temperatures and chemical attack.

Coal Gasifiers and Chemical Industry

Coal Gasifiers and Chemical IndustryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

Industrial High-temperature Furnace Body

Industrial High-temperature Furnace BodyRefractory bricks are often used to manufacture industrial furnace bodies, such as high-temperature smelting furnaces, incinerators, glass furnaces, steel furnaces, etc.

Coal gasifiers and chemical industry

Coal gasifiers and chemical industryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

Production Process of Refractory Fire Bricks

We have our own factory with professional technical team and production equipment.

With Fully automatic batching system; 20 sets of 400-1000 ton forming presses; 2 * 168m high-temperature tunnel kilns; 20000㎡ storage workshop.

Ensure product quality, improve production efficiency, and provide customers with the most satisfactory products and services.

Certificates Of Kerui Refractory

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides,

Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

Kerui Refractory Products Packaging & Shipping

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism.

If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

Customer Case Of Kerui Refractory

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania.

We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ repeat orders and referrals.

-

5Continents

-

50+Countries

-

1700+Successful Cases

-

4500+Customers