Refractory Bricks

- High Alumina Brick

- Silica Fire Brick

- Corundum Brick

- Fire Clay Brick

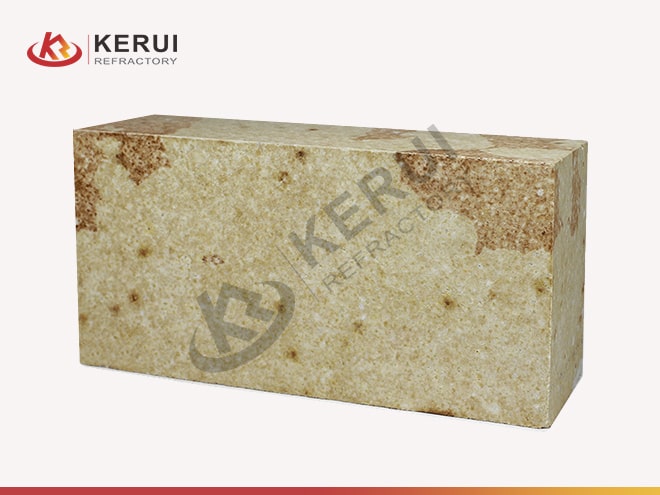

- Al2O3: 55-80%;

- Refractoriness Under Load: 1420-1530℃;

- Cold crushing strength: 40-70MPa;

- Standard Size: 230*114*65mm;

- Color: Yellow;

- Max service temp: 1800℃;

- Al2O3: Max service can up to 95%;

- Sample: available;

- Apparent Porosity, %: ≤26;

- Cold Crushing Strength, MPa: ≥40;

- Price: Low Ex-factory Price;

- Sample: available;

- MgO Chemical composition :≥95 %;

- Apparent Porosity :≤18 %;

- Bulk Density/ (g/cm³): 2.31-2.4

- Bending strength/ (MPa): ≥58.80

- MgO% (≥): 89-97.5

- Bulk Density (g/cm³): 2.85-3.0

- Refractoriness Under Load (℃): 1500-1700

- Size: 230*114*65mm; Customized Sizes

- MgO%: 69-85

- C%: 5-18

- Bulk Density (g/cm³): 2.79-3.05

- Sample: available;

- MgO%(≥): 45-65

- Cr2O3%(≥): 8-16

- Apparent Porosity/%(≤): 19-21

- Cold Crushing Strength (MPa): 20-35

- MgO% ≥:70/75/80 ZrO2 %≥:8/10/13;

- Apparent Porosity%≤:19;

- Bulk Density (g/cm3)≥:2.95;

- Refractoriness Under Load:≥1600 °C

- Al2O3% (≥): 62-70

- Fe2O3)/%(≤): 1.5-1.8

- Refractoriness Under Load (℃)(≥): 1760-1780

- Sample: available;

- Max service temp: 1700℃;

- More than 85% Al2O3 and 0.45% Fe2O3;

- Color: White;

- More than 55MPa cold crushing strength;

- Bulk density g/cm3:≥ 3.15;

- Cold Crushing Strength (Mpa)≥90;

- Apparent Porosity (%):≤17;

- Size: 230*114*65mm; Customized Sizes

- Al2O3:≥30-70%;

- Bulk Density: 1.9-2.35g/cm³

- Refractoriness Under Load: 1250-1480ºC;

- Sample: available;

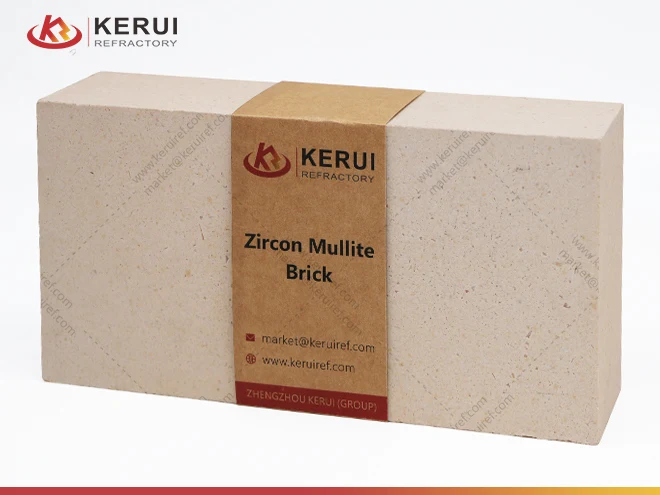

- ZrSiO4: ≥15-65%;

- Bulk Density: 2.7-3.7g/cm³;

- Refractoriness Under Load: 1550-1650ºC;

- Cold Crushing Strength: ≥100MPa;

- ZrO2%: ≥ 16

- Fe2O3%: ≤ 0.5

- Bulk Density (g/cm³): ≥ 2.70

- Cold Crushing Strength/MPa: ≥ 70

- Apparent porosity %: ≤20

- Refractoriness under load°C: ≥1650℃

- Al2O3: ≥45%

- Bulk density g/cm3: ≥3.2

- Bulk density g/cm3:≥ 3.15;

- Cold Crushing Strength (Mpa)≥90;

- Apparent Porosity (%):≤17;

- Size: 230*114*65mm; Customized Sizes

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Bulk Density (g/cm³)(≥): 2.90

- Cold Crushing Strength(≥): 50MPa

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Certification: ISO9001/ISO14001 /ISO45001/ISO50001

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Bulk Density (g/cm³)(≥): 2.90

- Sample: testing of sample is available

- Al2O3/%: 95-98

- SiO2/%: 0.15-0.5

- Fe2O3/%: 0.1-0.3

- Refractoriness Under Load: 1700MPa

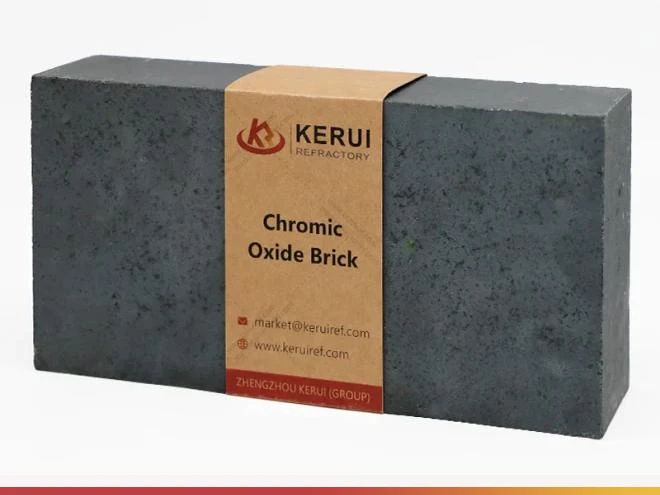

- Cr2O3 %≥:50-93;

- Apparent Porosity %:≤16;

- Bulk Density g/cm3≥:3.5-4.25;

- Load softening temperature, 0.2MPa 0.6%:≥1700;

- Bulk density g/cm3: ≥3.25;

- Apparent Porosity %: ≤15;

- Pressure strength(Mpa)≥1800;

- Load softening temperature(0.2Mpa T0.6 ℃): ≥168;

- Bulk density g/cm3: ≥1.7

- Compressive strength / Mpa: ≥36

- Oxidation rate /%: ≤8

- Average pore size: ≤0.1

- SiO2%: ≥94

- Fe2O3/%: ≤1.4

- True Density (g/cm³): ≤2.35

- Refractoriness Under Load (℃): ≥1650

- Al2O3 ≥/%: 60-65

- Bulk Density: 2.55-2.65g/cm³

- Sample: testing of sample is available

- Cold crushing strength: 85-90MPa

- Al2O3: ≥60-65%;

- SiO2: ≥32-37%;

- Bulk Density: 2.40-2.55g/cm³;

- Cold Crushing Strength: 45-60MPa;

- Holes: 7/19/31/37/65/others;

- Delivery: 15-30 Working Days;

- Price: Low Ex-factory Price;

- Sample: available;

- Al2O3 %: >36

- Apparent porosity %: 17-26;

- Bulk Density g/cm3: >2.1;

- Refractoriness ℃: >1700;

- Al2O3(%)≥: 42-72

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.6-1.1

- Cold Crushing Strength (MPa)≥: 1.5-3.5

- MgO+CaO% (≥):92-94;

- CaO% (≥):18-48;

- Apparent Porosity(%):15.0;

- Cold Crushing Strength (MPa):60;

- Acid Resistance ≥/%: 99.8

- Water Absorption ≤/%: 2

- Bulk Density/ (g/cm³): 2.31-2.4

- Bending strength/ (MPa): ≥58.80

- Al2O3(%)≥: 40-77

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.55-1.35

- Cold Crushing Strength (MPa)≥: 0.9-3.5

Insulation Bricks

- Al2O3≥: 48%

- Fe2O3≤: 2.0%

- Bulk Density (g/cm³): 0.5-1.2

- Cold Crushing Strength(MPa)≥: 1.2-4.5

- SiO2% (≥): 91

- Bulk Density (g/cm³): 1.0-1.2

- Refractoriness Under Load (℃)≥: 1400-1520

- Cold Crushing Strength (MPa)≥: 2.0-5.0

- Al2O3(%)≥: 40-77

- Fe2O3(%)≤: 0.5-1.0

- Bulk Density (g/cm³)≤: 0.55-1.35

- Cold Crushing Strength (MPa)≥: 0.9-3.5

- Bulk Density (g/cm³)≤: 0.5-1.5

- Thermal Conductivity (W/m·k)≤: 0.23-0.65

- Cold Crushing Strength (MPa)≥: 0.8-6

- Permanent Linear Change/%: -2-1

- Al2O3≥/%: 90-99

- ω (SiO2) ≤/%: 0.3

- Bulk Density (g/cm³): 1.3-1.9

- Cold Crushing Strength ≥/MPa: 6-18

Monolithic Refractories

- Al2O3%: 40-95

- Bulk Density: (g/cm³): 1.8-2.5

- Compressive Strength: (MPa): 20-150

- Max Service Temperature: (℃): 1300-1800

- Al2O3: 30-90

- Bulk Density (g/cm³): 1.9-3.15

- Compressive Strength (MPa): 20-100

- Max Working Temperature/℃: 1400-1800

- Al2O3%: 40-78

- Fe2O3%: 0.7-1.2

- Classification Temperature/℃: 1300-1600

- Refractoriness Underload/℃: 1320-1600

- Al2O3% (≥): 50-81

- Fineness(d50/μm): 5-13

- Flexural Strength(72h)/Mpa: 6-12.5

- Compressive Strength (72hrs)/MPa: 40-82

- Al2O3%: 50-81

- Fineness(d50/μm): 5-13

- Flexural Strength/Mpa(24h): 5.0-10.5

- Compressive Strength/Mpa(24h): 30-72

- Al2O3(%): 50-81

- CaO(%): 17.5-30.5

- Fineness(d50/μm): 5-13

- Compressive Strength (72hrs) (MPa):40-82

- Al2O3≥/%: 45-92

- SiO2≥/%: 5-50

- Bulk Density (g/cm³): 2.3-3

- Cold Crushing Strength/Mpa: 72-85

- Al2O3 ≥/%: 80-95

- Bulk Density≥/(g/cm³): 2.7-3.2

- Flexural Strength ≥/MPa: 9-11

- Compressive Strength ≥/MPa: 60

- Al2O3≥/%: 55-70

- Bulk Density≥/(g/cm³): 2.3-2.6

- Flexural Strength ≥/MPa: 7-9

- Max Service Temperature (℃): 1300-1500

- Bulk Density(g/cm³): 0.5-1.8

- Max. Service Temperature/℃: 1150-1350

- Cold Crushing Strength(110℃*24h)≥: 1.5-20MPa

- Thermal Conductivity (W/m·k)350℃: 0.15-0.65

- Al2O3≥/%: 50-80

- Bulk Density ≥/ (g/cm³): 2.15-2.65

- Cold Modulus of Rupture ≥/MPa: 4-7

- Cold Crushing Strength ≥/Mpa: 25-40

- Maximum Service Temperature ℃: 1550

- Bulk Density(g/cm³)≥ : 2.7

- 1100℃ Cold Crushing Strength(Mpa) ≥ : 100

- Linear Dimensional Change % ≤ : -0.3

- SiO2% (≥): 45-52

- Bulk Density (g/cm³): 1.6-2

- Acid Resistance% (≥): 95

- Cold Crushing Strength (MPa): 5-10

- Al2O3≥/%: 70-85

- Bulk Density ≥/ (g/cm³): 2.8-3.1

- High strength and wear resistance

- High density, low porosity

- SiC+C≥/%: 58-83

- Good resistance to erosion

- Abrasiveness resistance

- For cement kiln, EAF and steel ladel

- Al2O3 ≥/%: 45-95

- Cao≥/%: 1.15

- Bulk Density (g/cm3) ≥2.35-3.2

- Refractoriness ≥1710-1790℃

- Al2O3 ≥/%: 70-80

- Better thermal shock resistance

- Used in building material industry

- Sample: testing of sample is available

- Plasticity Index%:12-35

- Al2O3% (≥):35-80

- Bulk Density (g/cm³):2.15-2.65

- Compressive Strength (Mpa):6.0-8.0

- Al2O3% (≥): 32-70

- Fe2O3% (≥): 1.1-4.5

- Type:Dense Gunning Material

- Shelf Life (months):9

- Strong Acid Resistance

- Good Adhesion

- High Sealing Performance

- Good Heat Resistance

Ceramic Fiber Products/Calcium Silicate Board

- Al2O3≥/%: 35-52

- Bulk Density (g/cm³): 64-128

- Classification Temperature (℃): 1260-1430

- Shot Content ≤/%: 12-15

- Modules of Rupture ≥/MPa: 0.3

- Bulk Density (g/cm³): 250-360

- Classification Temperature (℃): 1260-1430

- Loss of Ignition ≤/%: 6

- Color: White

- Organic Content ≤/%: 15

- Bulk Density (kg/m³): 500

- Continuous Temperature Use Limit/℃: 650-1000

- Bulk Density (g/cm³): 200-240

- Classification Temperature (℃): 1260-1350

- Tensile Strength/MPa: 0.4-0.7

- Thickness (mm): 0.5-6.4

- Al2O3≥/%: 35-52

- SiO2≥/%: 47-55

- Classification Temperature (℃):1260-143

- Shot Content ≤/%:12-15

- Bulk Density (g/cm³): 380-500

- Continuous Temperature Use Limit/℃: 650-1000

- Organic Content ≤/%: 15

- Reinforcement: Glass Fiber/Stainless Steel

- Color: White

- Organic Content ≤/%: 15

- Bulk Density (kg/m³): 500

- Continuous Temperature Use Limit/℃: 650-1000

- Al2O3% (≥): 35-52

- Bulk Density (g/cm³): 160-220

- Classification Temperature (℃): 1260-1430

- Permanent Linear Change ≤/%: 2.5-3.0

- Thickness: 6-18mm

- Bulk Density (kg/m³): 230±10%

- Modules of Rupture ≥/MPa: 0.45-0.55

- Compressive Strength ≥/MPa: 0.75 -0.95

Kiln Furniture/Shelves

- Silicon Carbide Kiln Furniture

- Cordierite Mullite Kiln Shelves

- For Ceramic And Glass Industries

- Factory Supply, Lower Price

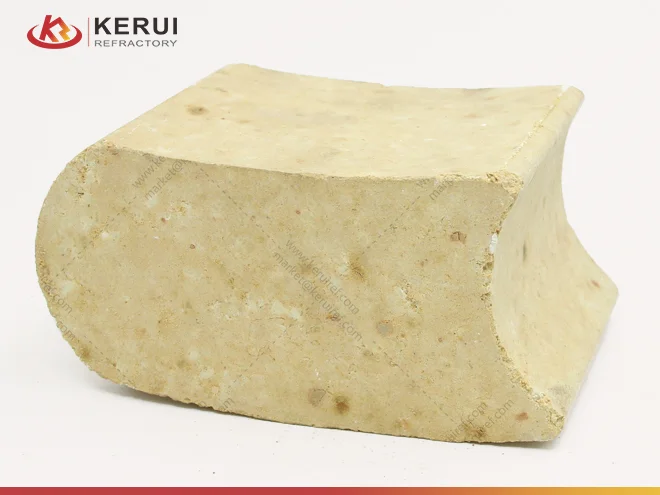

- Corundum-mullite Type

- Cordierite-mullite Type

- Chrome Corundum-mullite Type

- Zirconium Corundum-mullite Type