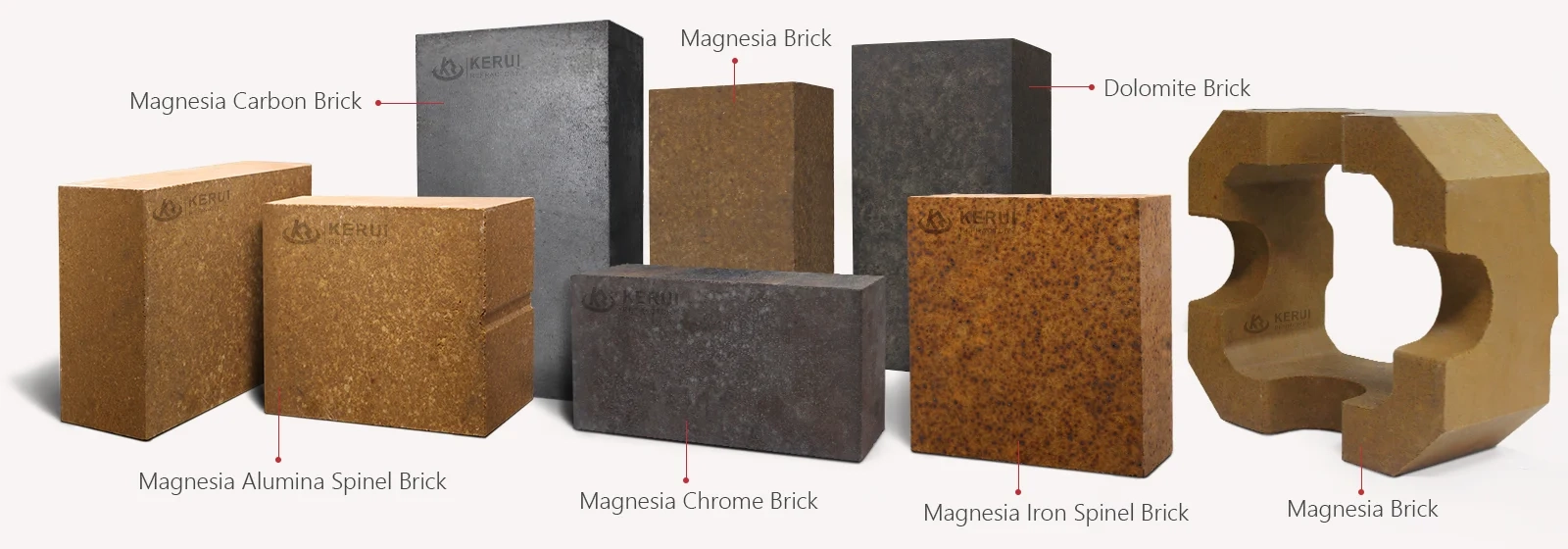

Magnesia Brick

Mainly used in alkaline open-hearth furnaces, electric furnace bottoms and furnace walls for steelmaking.

- MgO% (≥): 89-97.5

- Bulk Density (g/cm³): 2.85-3.0

- Refractoriness Under Load (℃): 1500-1700

- Cold Crushing Strength (MPa): 45-60

- Certification: ISO9001/ISO14001/ISO45001/ISO50001

- Sample: testing of sample is available

Description of Magnesia Brick

The main component of magnesia bricks is magnesium oxide, and the main crystal is periclase. It is widely used in steel-making furnace linings, ferroalloy furnaces, iron mixing furnaces, non-ferrous metallurgical industrial furnaces, lime kilns for building materials, glass industry re-generator grids and Heat exchangers, high-temperature calcining kilns and tunnel kilns in the refractory industry, etc.

Kerui Magnesia Brick Technical Data Sheet

| Item/Grade | M-98 | M-97A | M-97B | M-95A | M-95B | M-91 | M-89 | |

|---|---|---|---|---|---|---|---|---|

| ω (MgO)/% | μ0 ≥ | 97.5 | 97.0 | 96.5 | 95.0 | 94.5 | 91.0 | 89.0 |

| σ | 1.0 | 1.5 | ||||||

| ω (SiO2)/% | μ0 ≤ | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | / | / |

| σ | 0.30 | |||||||

| ω (CaO)/% | μ0 ≤ | / | / | / | 2.00 | 2.00 | 3.00 | 3.00 |

| σ | 0.30 | |||||||

| Apparent Porosity/% | μ0 ≤ | 16 | 16 | 18 | 16 | 18 | 18 | 20 |

| σ | 1.5 | |||||||

| Bulk Density (g/cm³) | μ0 ≥ | 3.00 | 3.00 | 2.95 | 2.90 | 2.85 | ||

| σ | 0.30 | |||||||

| Cold Crushing Strength/MPa | μ0 ≥ | 60 | 60 | 60 | 60 | 50 | ||

| Xmin | 50 | 50 | 50 | 50 | 45 | |||

| σ | 10 | |||||||

| 0.2MPa Refractoriness Underload/℃ | μ0 ≥ | 1700 | 1700 | 1650 | 1560 | 1500 | ||

| σ | 15 | |||||||

| Permanent Linear Change/% | Xmin~Xmax | 1650℃*2h -0.2-0 |

1650℃*2h -0.3-0 |

1600℃*2h -0.5-0 |

1600℃*2h -0.6-0 |

|||

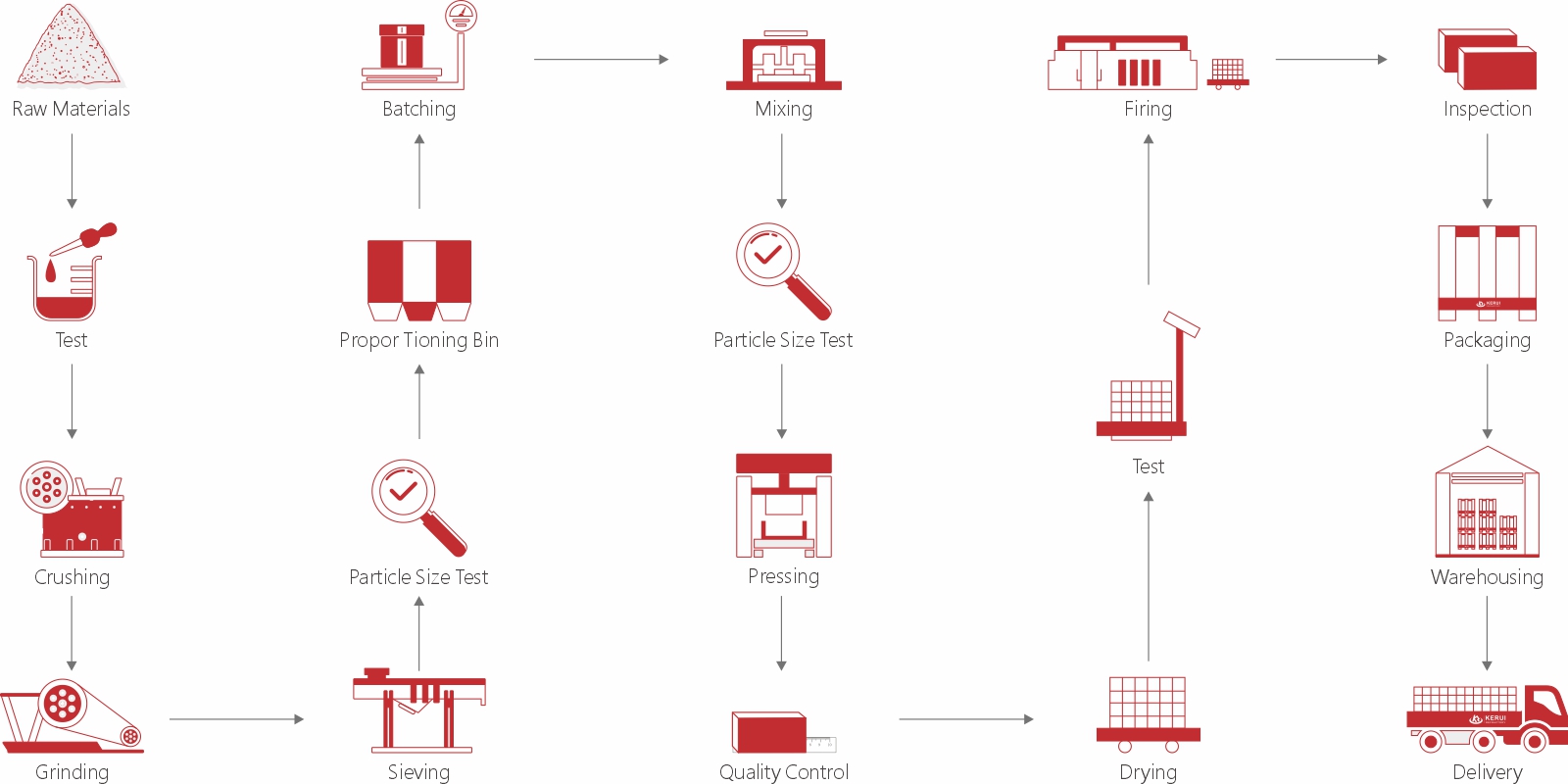

Manufacturing Process of Magnesia Brick

We have our own factory with professional technical team and production equipment. With Fully automatic batching system; 20 sets of 400-1000 ton forming presses; 2 * 168m high-temperature tunnel kilns; 20000㎡ storage workshop. Ensure product quality, improve production efficiency, and provide customers with the most satisfactory products and services.

Advantages of Magnesia Brick

Refractory Performance

Refractory magnesia bricks can withstand extremely high temperatures, often reaching over 1500 degrees Celsius. Magnesia brick is an excellent refractory material that can withstand high temperature environments without losing its structural strength.

Excellent Slag Resistance

Magnesia bricks are alkaline refractory bricks that have strong resistance to alkaline slags, and are often used as masonry materials for alkaline kilns. Magnesia bricks have high strength and hardness and can withstand greater pressure and load.

Good Thermal Conductivity

Refractory magnesia bricks have high thermal conductivity and can absorb and release heat quickly. This makes it very effective in applications where rapid heat transfer is required, such as high-temperature furnaces, kilns, etc.

Long Life and Durability

Magnesia refractory bricks have a long service life due to their resistance to high temperature and chemical attack. It is not easily damaged and degraded, and can stably assume the function of a fire-resistant structure for a long time

Thermal Expansion Adaptability

The linear expansion coefficient of magnesia bricks increases with temperature. In high-temperature environments, it can quickly conduct and dissipate heat, prevent the accumulation of thermal stress, and reduce the risk of structural damage.

Lightweight Material

Compared with other refractory materials, magnesia bricks have lower density and lighter weight. This makes it useful in some situations where structural load needs to be reduced, and also facilitates the construction and transportation process.

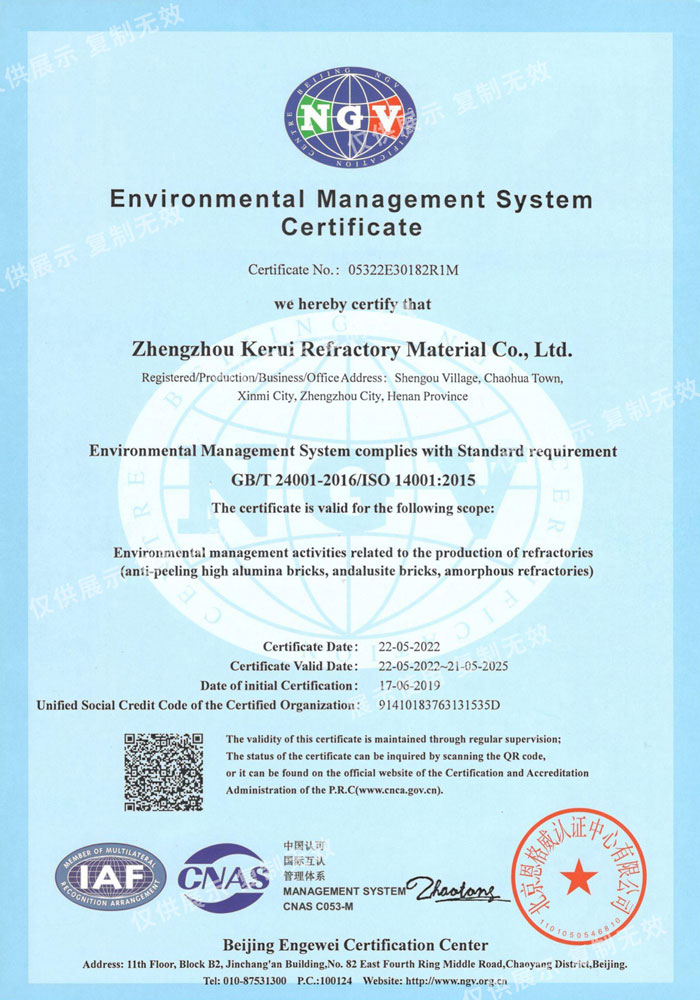

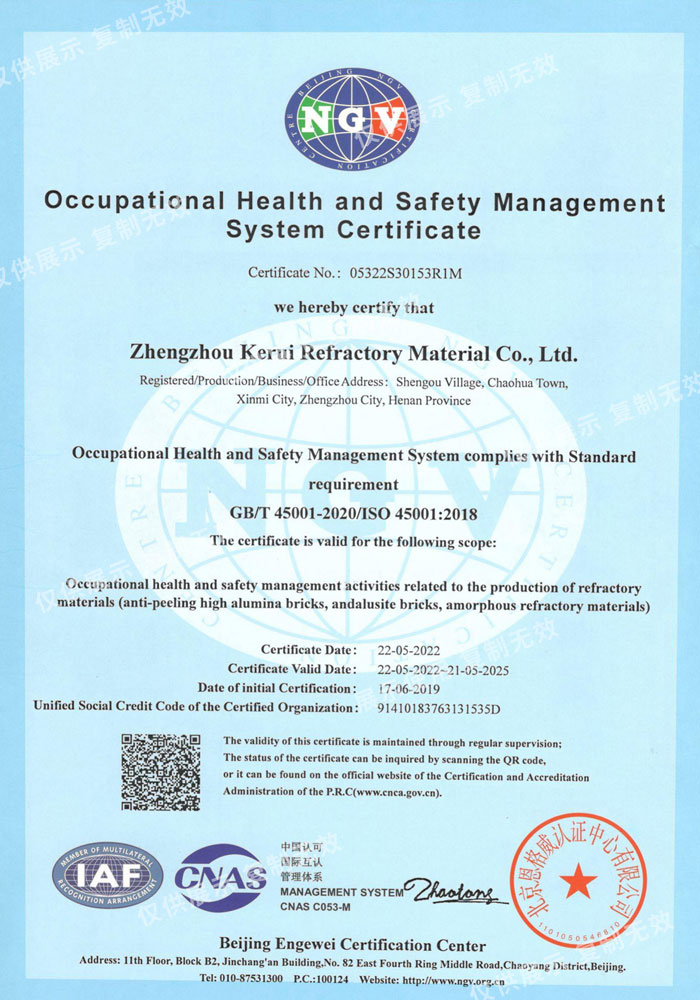

Certificates of Kerui Refractory

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

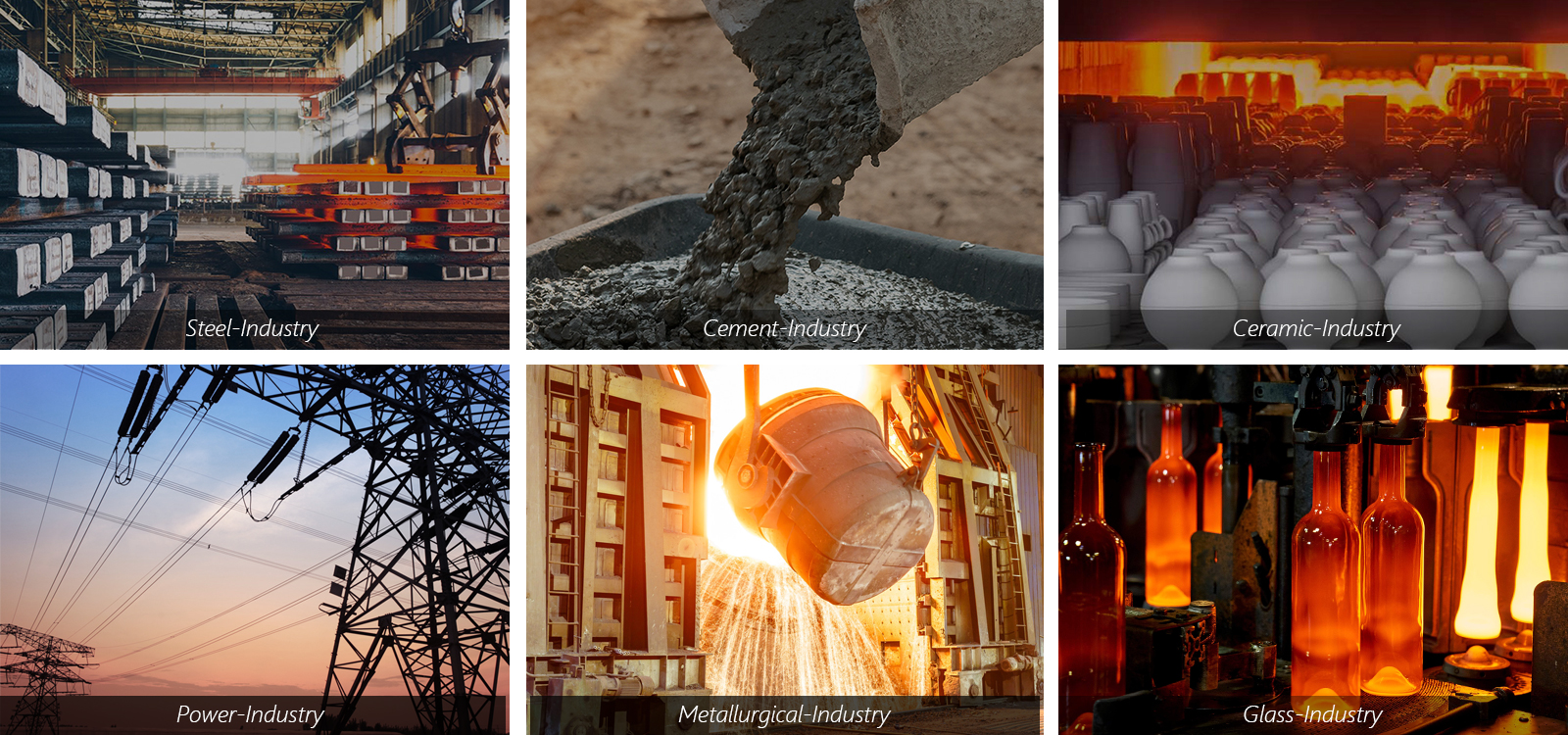

Application of Magnesia Brick

Metallurgical Industry

Refractory magnesia bricks are widely used in high-temperature equipment in the metallurgical industry, such as steel furnaces, non-ferrous metal smelting furnaces, converters, electric furnaces and railway blast furnaces. They can withstand high temperatures and chemical attack, protect the furnace structure and keep the temperature inside the furnace stable.

Glass Industry

In the glass manufacturing process, refractory magnesia bricks are often used in equipment such as glass kilns, fiberglass ladles and glass tanks. They are able to withstand the high temperatures of glass melting and have good resistance to thermal shock and chemical stability. Ensure the stability and efficiency of the glass production process.

Chemical industry

Refractory magnesia bricks are widely used in chemical plants and refineries. They resist corrosion from chemicals and are used in equipment such as reactors, furnaces, tanks and pipes. Refractory magnesia bricks are ideal for handling corrosive media and high-temperature reactions in the chemical industry.

Electric Power Industry

In the electric power industry, refractory magnesia bricks are often used in high-temperature equipment such as boilers, combustion chambers and chimneys in power stations. They are able to withstand high temperatures and thermal stresses, protect equipment structures and improve combustion efficiency.

High-temperature Furnace

Refractory magnesia bricks are widely used in various high-temperature furnaces, including steel furnaces, aluminum furnaces, copper furnaces, glass furnaces, cement kilns, etc. They are able to withstand high temperatures and thermal shocks and maintain the structural stability of the furnace. Ideal for various high temperature furnaces.

Other Industries

Refractory magnesia bricks can also be used in some other fields, such as the construction industry, ceramics industry, ceramic kilns, etc. In these applications, refractory magnesia bricks can be used in furnaces, chimneys, furnace linings, insulation panels and other structures to provide fire resistance and heat insulation functions.

Laboratory of Kerui Refractory

Kerui has a professional quality inspection laboratory. High temperature reheating/load softening creep test furnace;Compressive/flexural strength testing bench for refractory materials; Composition testing and inspection platform for refractory materials; Laboratory for physical/chemical properties for refractory materials.

KERUI REFRACTORY PRDUCTS PACKAGING&SHIPPING

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism. If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

CUSTOMER CASE OF KERUI REFRACTORY

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania. We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ return orders and referrals.