High Alumina Fire Brick

Used for lining steel-making electric furnaces, glass melting furnaces, and cement rotary furnaces.

- Al2O3: 48-80%;

- Refractoriness Under Load: 1420-1530℃;

- Cold crushing strength: 40-70MPa;

- Standard Size: 230*114*65mm;

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Sample: available;

Description of High Alumina Fire Brick

High alumina brick is a kind of aluminum silicate refractory product with aluminum oxide (Al2O3) content higher than 48%. It is formed and calcined from bauxite or other raw materials with high alumina content. High thermal stability, refractoriness above 1770°C. It has good slag resistance and is used for the lining of masonry steelmaking electric furnaces, glass melting furnaces, and cement rotary furnaces.

Technique Data of Kerui High Alumina Fire Bricks

| Item/Grade | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-55 | LZ-48 | LZ-75G | LZ-65G | LZ-55G | |

|---|---|---|---|---|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 80 | 75 | 70 | 65 | 55 | 48 | 75 | 65 | 55 |

| σ | 1.5 | |||||||||

| Apparent Porosity/% | μ0 ≤ | 21 (23) | 24 (26) | 24 (26) | 24 (26) | 22 (24) | 22 (24) | 19 | 19 | 19 |

| σ | 1.5 | |||||||||

| Cold Crushing Strength/MPa | μ0 ≥ | 70 (60) | 60 (50) | 55 (45) | 50 (40) | 45 (40) | 40 (35) | 65 | 60 | 50 |

| Xmin | 60 (50) | 50 (40) | 45 (35) | 40 (30) | 35 (30) | 30 (35) | 55 | 50 | 40 | |

| σ | 15 | |||||||||

| 0.2MPa Refractoriness Underload/℃ | μ0 ≥ | 1530 | 1520 | 1510 | 1500 | 1450 | 1420 | 1520 | 1500 | 1470 |

| σ | 13 | |||||||||

| Permanent Linear Change/% | Xmin Xmax |

1500℃*2h -0.4~0.2 |

1450℃*2h -0.4~0.1 |

1500℃*2h -0.2~0.1 |

1450℃*2h -0.2~0 |

|||||

Advantages of High Alumina Refractory Bricks

High refractoriness

The refractoriness of high-alumina bricks is higher than that of clay bricks and semi-silica bricks, reaching 1750~1790°C, which is a high-grade refractory material.

Load Softening Temperature

Because the Al2O3 in high alumina products is high, the amount of impurities is less, and the formation of fusible glass is less, the softening temperature under load is higher than that of clay bricks.

Excellent thermal shock resistance

High alumina bricks have excellent thermal shock resistance, so that it can withstand rapid changes in temperature without cracking.

Excellent slag resistance

The content of Al2O3 in high alumina bricks is high, which is close to neutral refractory materials, and can resist the erosion of acid slag and alkaline slag. Because it contains SiO2, the ability to resist alkaline slag is weaker than that of acid slag.

Good mechanical strength

Good mechanical strength helps to resist mechanical stress such as thermal expansion and contraction.

Low Thermal Conductivity

Low thermal conductivity means they provide excellent insulation and help reduce heat loss.

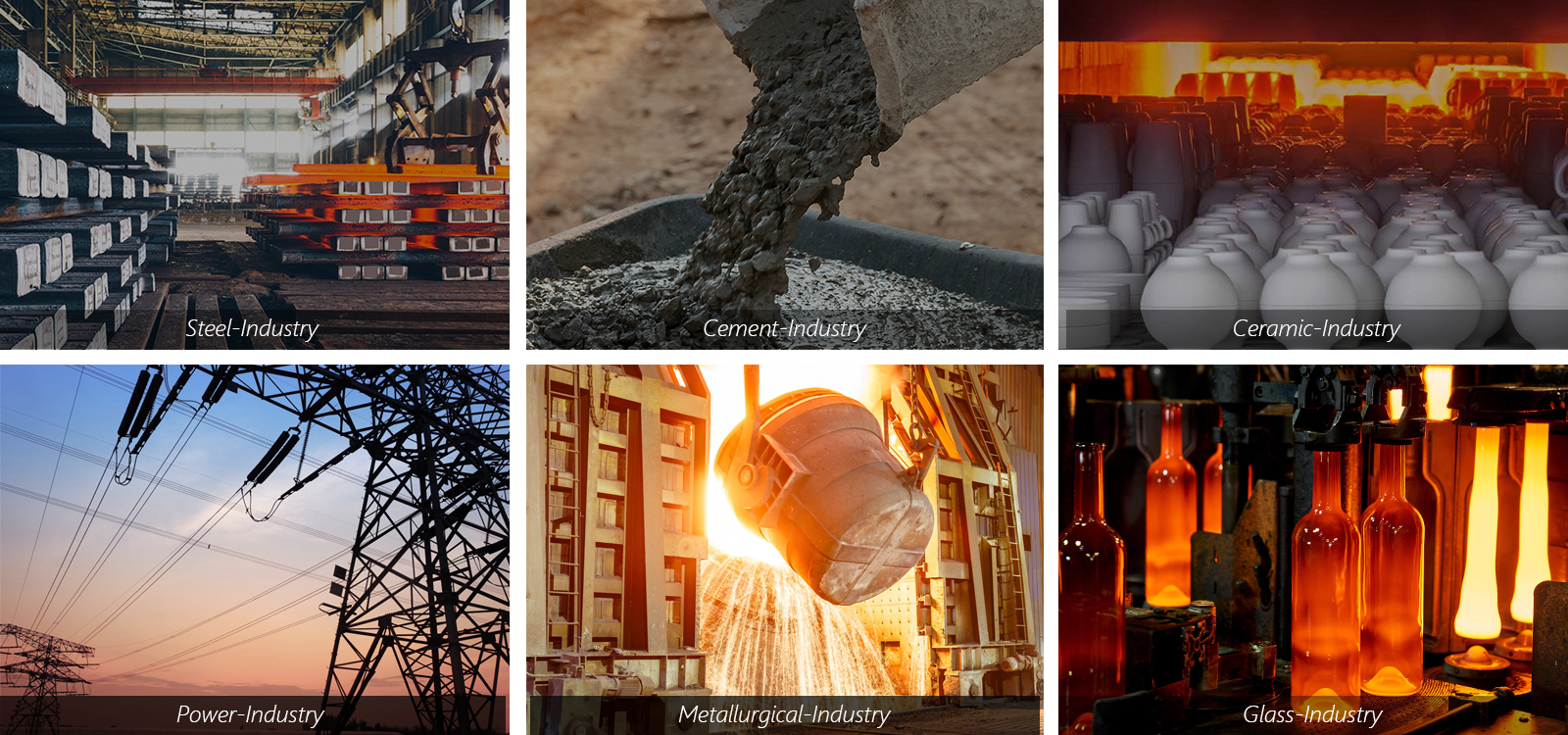

Application of High Alumina Refractory Bricks

- Iron and Steel Manufacturing Industry: blast furnace, hot blast stove, electric furnace, ladle, tundish, heating furnace, refining furnace, heating furnace, annealing furnace, cupola;

- Non-ferrous Metal Industry: smelting furnace,refining furnace, reverberatory furnace, converter;

- Building Materials Industry: cement kiln, glass kiln, ceramic kiln, lime kiln, kiln car, tunnel kiln;

- Energy and Incineration: coke oven, circulating fluidized bed boiler, carbon roaster, incinerator.