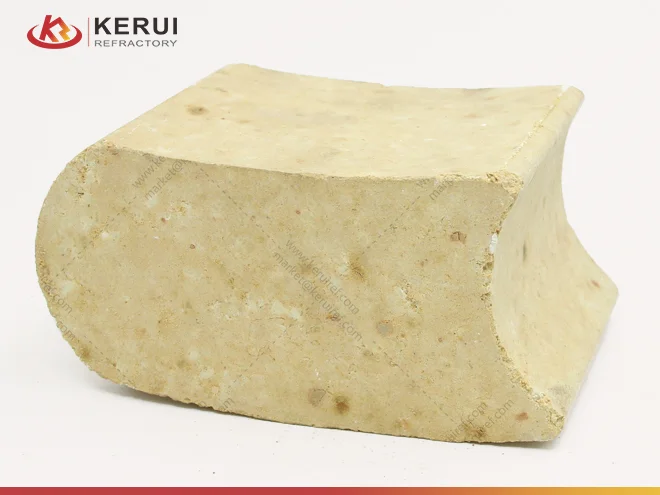

Curved Fire Brick

- Apparent Porosity, %: ≤26;

- Cold Crushing Strength, MPa: ≥40;

- Good corrosion resistance;

- Good spalling resistance and wear resistance;

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Sample: available;

Description of Curved Fire Brick

Curved refractory brick is a common semicircular design special-shaped brick, usually made of high alumina or clay, with good fire resistance. It is mainly used for lining of high temperature resistant equipment such as industrial furnaces and boilers. Curved bricks can withstand temperatures up to 1400°C or higher.

Due to the special shape of curved bricks, it is suitable for circular hearths or curved structures. It is widely used in high temperature operations such as steelmaking and ceramic kilns.

Technique Data of Kerui Curved Fire Brick

| Item | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-60 | LZ-55 | LZ-48 | |

|---|---|---|---|---|---|---|---|---|

| Al2O3, /% | ≥ | 80 | 75 | 70 | 65 | 60 | 55 | 48 |

| Apparent Porosity, % | ≤ | 21 | 24 | 24 | 24 | 26 | 22 | 22 |

| Cold Crushing Strength, MPa | ≥ | 70 | 60 | 55 | 50 | 45 | 45 | 40 |

| 0.2MPa Refractoriness Under Load, ℃ | ≥ | 1530 | 1520 | 1510 | 1500 | 1430 | 1450 | 1420 |

| Permanent Linear Change, % | 1500℃*2h-0.4~0.2 | 1450℃*2h-0.4~0.1 | ||||||

Types of Curved Fire Brick

Curved refractory bricks can be classified according to their materials, shapes and uses. The following are the main classification methods:

▶ Classification by Material:

1.Clay Refractory Bricks: mainly made of clay, suitable for environments with temperatures not exceeding 1300°C.

2.High Alumina Refractory Bricks: contain a higher proportion of bauxite, have high refractoriness, and are suitable for higher temperature applications.

3.Magnesium Refractory Bricks: use magnesium ore as raw material, have excellent corrosion resistance, and are often used in metal smelting.

4.Silica Refractory Bricks: mainly composed of silicon dioxide, suitable for acidic environments.

▶ Classification by Shape

1.Standard Curved Bricks: have a standard semicircular design and are suitable for general furnace structures.

2.Special Curved Bricks: include a variety of non-standard shapes, such as grooves or special angle designs, to adapt to specific furnace structures.

▶ Classification by Use

1.Curved bricks for blast furnaces: specially designed for blast furnace linings, withstand extreme high temperatures and chemical erosion.

2.Curved bricks for electric furnaces: used for electric furnace linings, emphasizing electrical insulation and thermal stability.

3.Curved bricks for cement kilns: Designed for special needs in the cement production process.