Chrome Corundum Brick

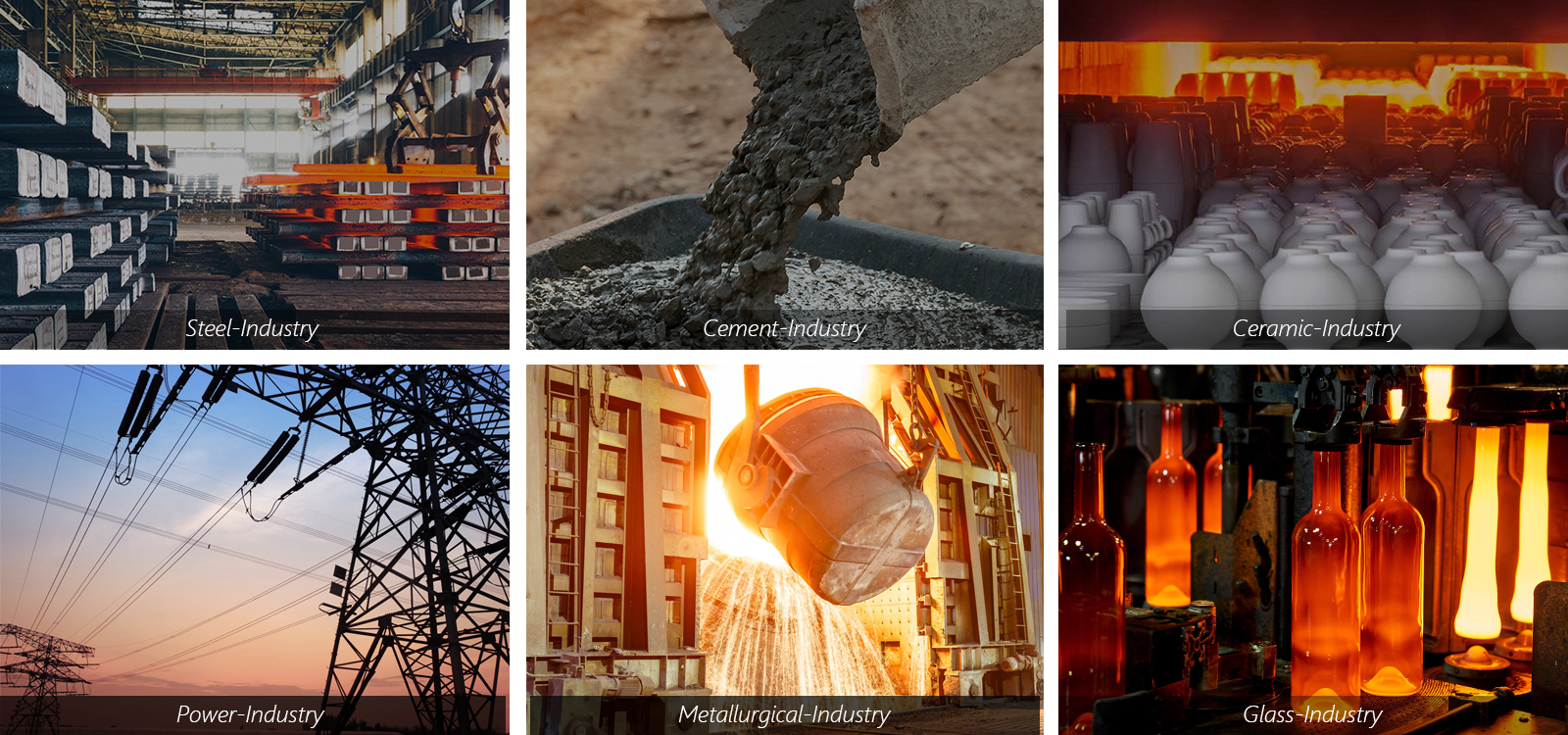

Used in steel-making furnaces and refining furnaces in the metallurgical industry, glass kilns in the glass industry, and high-temperature kilns in the ceramic industry.

- Bulk density g/cm3: ≥3.25;

- Apparent Porosity %: ≤15;

- Pressure strength(Mpa)≥1800;

- Load softening temperature(0.2Mpa T0.6 ℃): ≥168;

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Sample: available;

Description of Chrome Corundum Brick

Chrome corundum bricks are made of α-Al2O3 as raw material, with appropriate amount of chromium oxide powder and chrome corundum clinker fine powder added, and then formed and fired at high temperature. The main mineral composition is α-Al2O3-Cr2O3 solid solution, the secondary mineral is composed of a small amount of composite spinel (or no composite spinel), and the chromium oxide content is 1% to 30% of the refractory bricks.

Technique Data of Kerui Chrome Corundum Brick

| Fused Chrome Corundum Brick | KR-G92-Cr | |

|---|---|---|

| Chemical Composition(%) | Al2O3 | ≥92 |

| SiO2 | ≤1.0 | |

| Fe2O3 | ≤0.3 | |

| CaO | ≤1.2 | |

| Na2O | – | |

| ZrO2 | ≥3 | |

| Cr2O3 | ≥3 | |

| Apparent Porosity (%) | ≤15 | |

| Bulk density(g/cm3) | ≥3.25 | |

| Pressure strength(Mpa) | ≥180 | |

| High temperature flexural strength(1250℃ Mpa) | ≥9.5 | |

| Refractoriness(℃) | ≥1900 | |

| Load softening temperature(0.2Mpa T0.6 ℃) | ≥1680 | |

| Burning line rate of change % (1500℃×2h) | ≤±1.2 | |

Advantages of Chrome Corundum Brick

Chrome corundum bricks are featured by high hardness, excellent wear resistance, good thermal shock resistance and high temperature resistance. They also have strong chemical stability and low thermal conductivity, ensuring reliable performance in harsh high-temperature environments.

Application of Chrome Corundum Brick

- Metallurgical industry:steelmaking furnace, refining furnace, etc.;

- Glass industry: glass kiln;

- Ceramic industry: high temperature kiln, which can resist high temperature erosion and scouring and increase the service life of the furnace.