Ceramic Fiber Blanket

- Al2O3≥/%: 35-52

- Bulk Density (g/cm³): 64-128

- Classification Temperature (℃): 1260-1430

- Shot Content ≤/%: 12-15

- Tensile Strength/kPa: 30-70

- Sample: testing of sample is available

Description of Ceramic Fiber Blanket

The ceramic fiber blanket is white in color, regular in size, integrated with heat insulation, and heat preservation functions, and does not contain any additives. Ceramic fiber blankets are made from spun ceramic fibers that have been needle punched to provide excellent handling strength for high-temperature insulation applications. It can maintain good tensile strength, and toughness when used in neutral and oxidizing atmospheres. Ceramic fiber blankets have excellent chemical properties and can be widely used in the fields of insulation, and heat insulation. It also includes several different types, such as ordinary ceramic fiber blankets, standard ceramic fiber blankets, high-purity ceramic fiber blankets, high-alumina ceramic fiber blankets, and zirconium-containing ceramic fiber blankets.

Kerui Ceramic Fiber Blanket Technical Data Sheet

| Item/Grade | STD Blanket | HP Blanket | HA Blanket | HZ Blanket | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Classification Temperature/℃ | 1260 | 1260 | 1350 | 1430 | ||||||

| Chemical Composition | ω (Al2O3) ≥/% | 43 | 44 | 52 | 35 | |||||

| ω (SiO2) ≥/% | 54 | 55 | 47 | 49 | ||||||

| ω (ZrO2) ≥/% | / | / | / | 15 | ||||||

| Color | White | White | White | White | ||||||

| Shot Content ≤/% | 15 | 15 | 15 | 12 | ||||||

| Bulk Density (kg/m³) | 64 | 96 | 128 | 96 | 128 | 96 | 128 | 96 | 128 | |

| Tensile Strength/kPa | 30 | 50 | 70 | 50 | 70 | 50 | 70 | 50 | 70 | |

| Permanent Linear Change ≤/% | 1000℃*24h 2.5 | 1100℃*24h 2.5 | 1200℃*24h 3.0 | 1350℃*24h 3.0 | ||||||

| Thermal Conductivity Coefficient /[W/(m·K)] | 200℃ | 0.07 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| 400℃ | 0.12 | 0.11 | 0.1 | 0.11 | 0.1 | 0.11 | 0.1 | 0.11 | 0.1 | |

| 600℃ | 0.2 | 0.19 | 0.18 | 0.19 | 0.17 | 0.18 | 0.16 | 0.16 | 0.15 | |

| 800℃ | 0.3 | 0.23 | 0.2 | 0.23 | 0.2 | 0.22 | 0.2 | 0.21 | 0.19 | |

| 1000℃ | 0.4 | 0.32 | 0.27 | 0.31 | 0.26 | 0.3 | 0.26 | 0.3 | 0.26 | |

Advantages of Ceramic Fiber Blanket

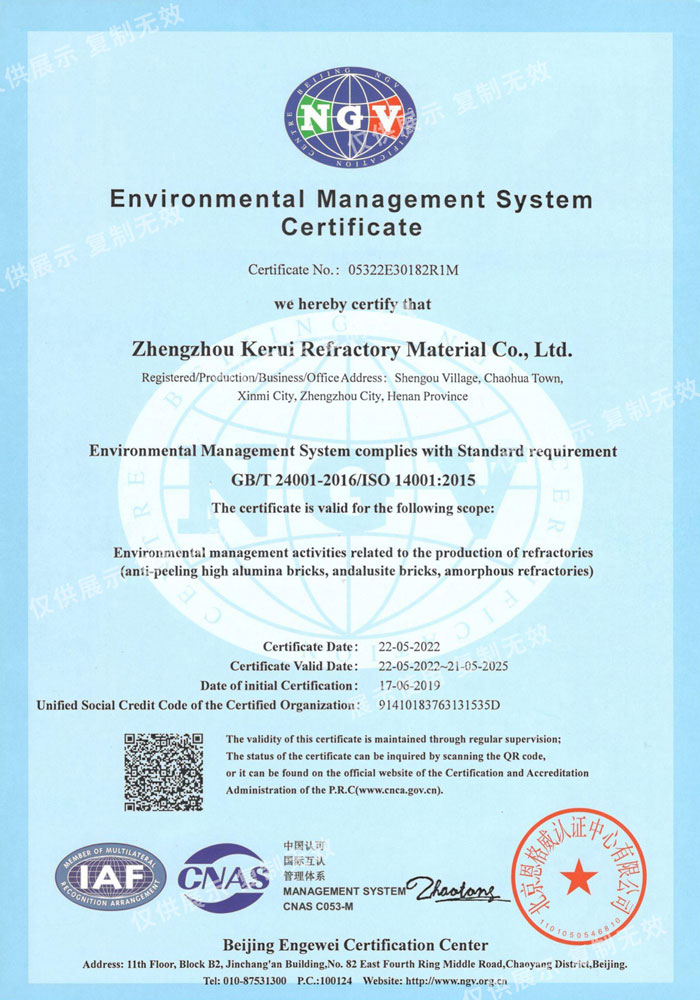

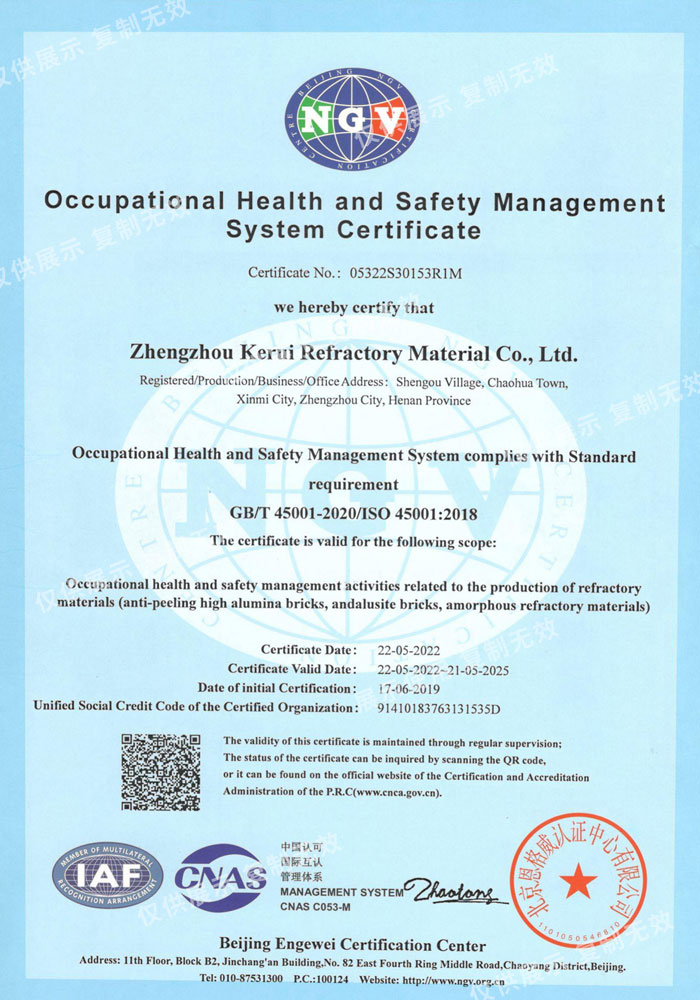

Certificates of Kerui Refractory

Kerui Group has a number of international certifications, such as,ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Kerui Refractory also has a number of domestic certifications.

KERUI REFRACTORY PRDUCTS PACKAGING&SHIPPING

Besides mainland China, Kerui Refractory has exported products to more than 50 countries and regions across 5 continents across the world, including Asia, Europe, America, Africa and Oceania. We have received recognition and high praise from customers all over the world, and are constantly receiving customers’ return orders and referrals.

Classification of The Ceramic Fiber Blanket

Laboratory of Kerui Refractory

Kerui has a professional quality inspection laboratory. High temperature reheating/load softening creep test furnace;Compressive/flexural strength testing bench for refractory materials; Composition testing and inspection platform for refractory materials; Laboratory for physical/chemical properties for refractory materials.

Application of Ceramic Fiber Blanket

High-Temperature Kiln

Ceramic fiber blankets are mainly used as heat insulation liners in high-temperature kilns and can be placed on the furnace wall, furnace roof, or furnace bottom to play a thermal insulation effect. It can also be used to seal the kiln, fill the gaps and irregular spaces of the kiln, and compensate for the thermal expansion and contraction of the furnace body. Thereby extending the service life of high-temperature kiln.

High-Temperature Pipe Insulation

Pipe Wrapping, ceramic fiber blankets can be directly used to directly wrap high-temperature pipes, thus forming a layer of heat insulation protection.

Pipe Filling, it can be used as pipe-filling material to fill the gaps around the pipe to reduce heat loss.

Pipe Sandwich, ceramic fiber blankets can be used to build pipe sandwich structures by placing them in the gap between the inside and outside of the pipe.