Chrome Brick

- Cr2O3 %≥:50-93;

- Apparent Porosity %:≤16;

- Bulk Density g/cm3≥:3.5-4.25;

- Load softening temperature, 0.2MPa 0.6%:≥1700;

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Sample: available;

Description of Chrome Brick

High chrome bricks are made of chromium oxide and alumina as the main raw materials, or a small amount of zirconium oxide is introduced. After high temperature firing into. The content of chromium oxide is not less than 75%, and the content of chromium oxide and alumina is not less than 98% of the shaped refractory products.

Technique Data of Kerui Chrome Brick

| Item | High chrome oxide brick | 80 chrome brick | 70 chrome brick | 60 chrome brick | 50 chrome brick |

|---|---|---|---|---|---|

| Cr2O3, % | ≥93 | ≥80 | ≥70 | ≥60 | ≥50 |

| Bulk density, g/cm3 | ≥4.25 | ≥4.1 | ≥3.7 | ≥3.6 | ≥3.5 |

| Apparent Porosity, % | ≤16 | ≤16 | ≤16 | ≤15 | ≤16 |

| Cold crushing strength, MPa | ≥100 | ≥120 | ≥120 | ≥120 | ≥120 |

| Load softening temperature, 0.2MPa 0.6% | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

Advantages of Chrome Brick

High chromium bricks have excellent resistance to leaching, high compressive strength at room temperature, excellent wear resistance, high temperature resistance, good thermal shock resistance, etc.

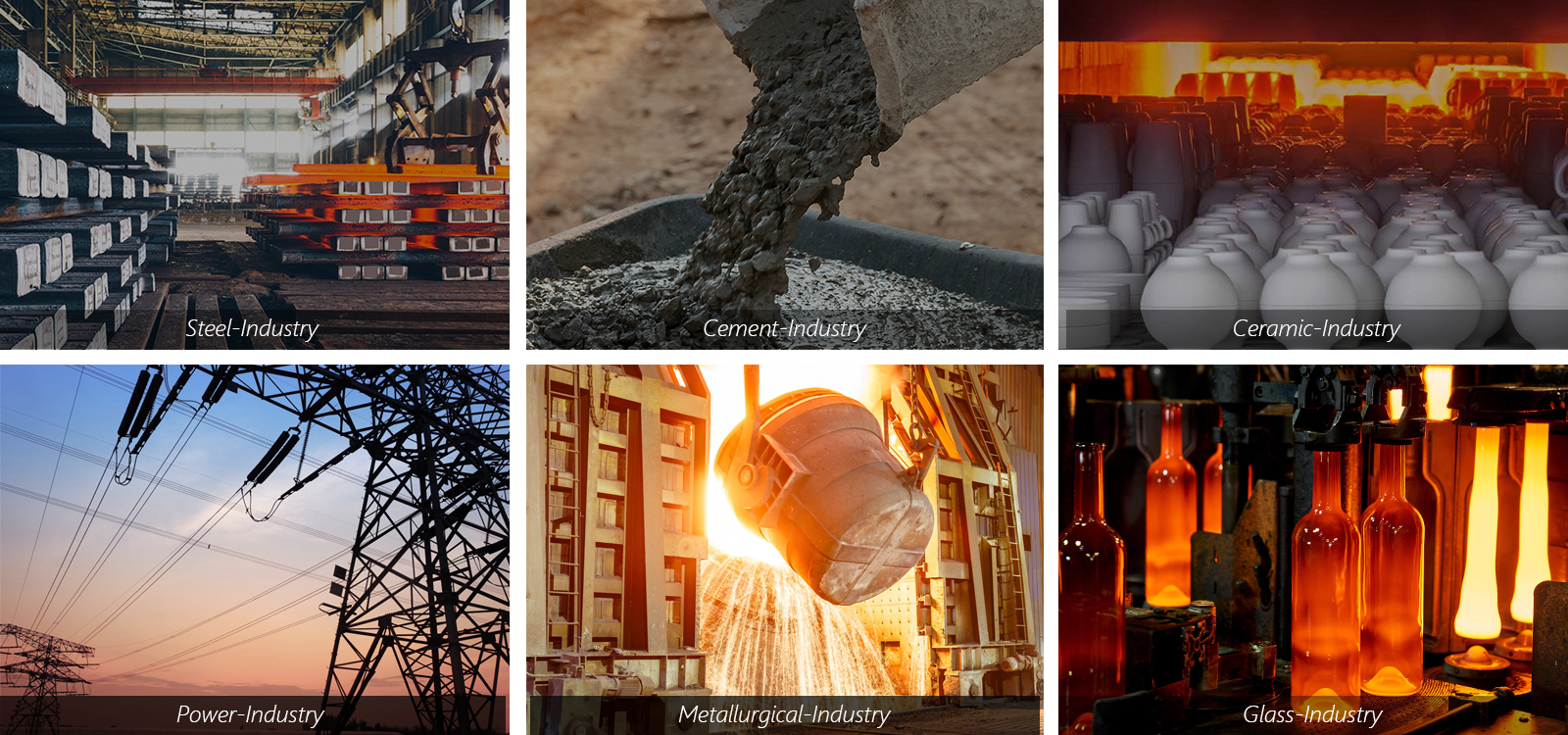

Application of High Chrome Bricks

High chrome bricks (Cr2O3≥90%) are mainly used in key parts of coal chemical industry, chemical kilns, alkali-free glass fiber kilns, garbage incinerators, gasification furnaces, etc. They can also be used for linings of carbon black furnaces, copper smelting furnaces, glass kiln melting pools, steel rolling heating furnace chutes, steel unloading platforms, etc.