Placa de fibra cerâmica

- Módulos de rutura ≥/MPa: 0,3

- Densidade aparente (g/cm³): 250-360

- Classificação Temperatura (℃): 1260-1430

- Perda de ignição ≤/%: 6

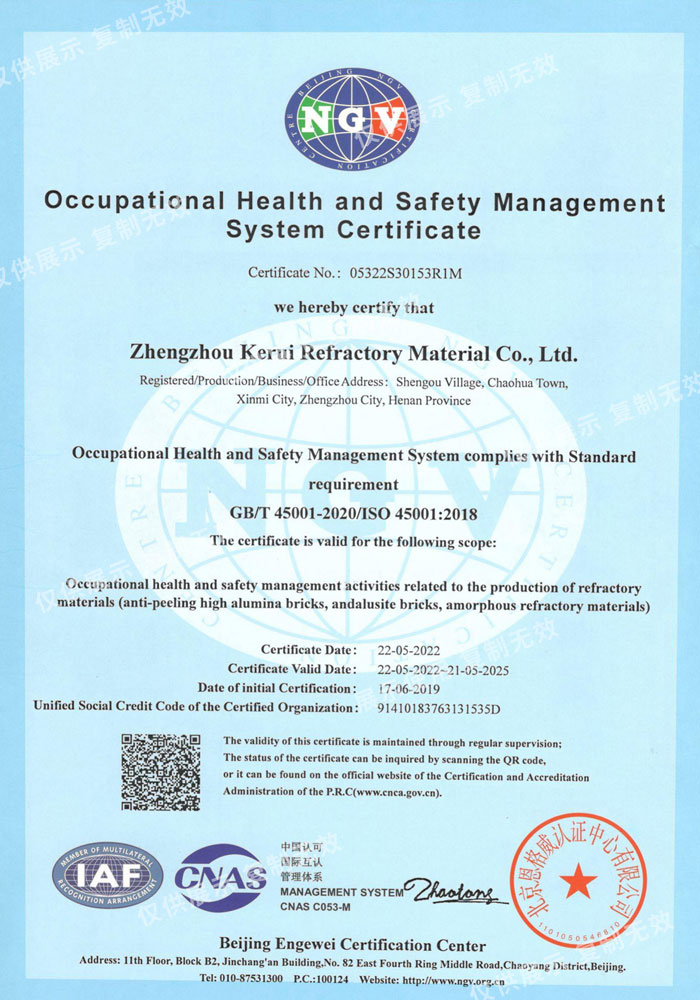

- Certificação: ISO9001/ISO14001/ISO45001/ISO50001

- Amostra: é possível testar a amostra

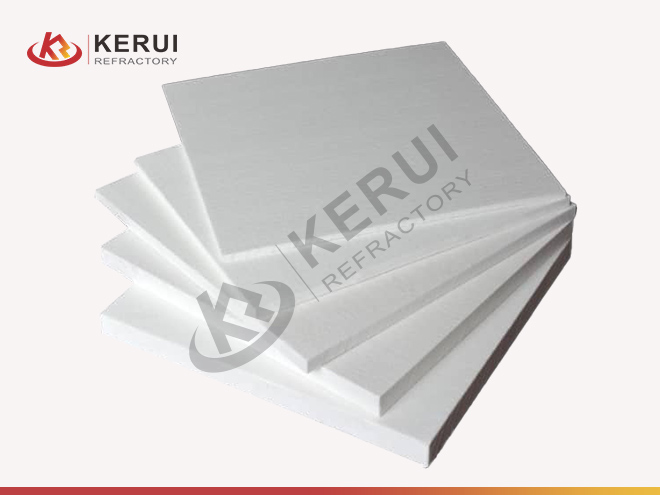

Descrição do painel de fibras cerâmicas

O painel de fibras cerâmicas é um tipo de material refratário, geralmente composto por alumina e silicato, e também é designado por painel de silicato de alumínio. A placa de fibra cerâmica é feita de algodão de fibra cerâmica, matérias-primas refractárias naturais e uma pequena quantidade de aglutinante orgânico como principais matérias-primas, e é processada por uma linha de produção contínua de controlo totalmente automatizada. Após o aquecimento, tem muito boas propriedades mecânicas e tem um certo suporte de dureza, o que proporciona uma forte garantia para o forno poupar energia e reduzir o consumo, alta qualidade e alto rendimento.

Ficha técnica do painel Kerui Ceramic Fiber Board

| Item/Grau | Direção de DST | Placa HP | Quadro de HA | Quadro HZ | |

|---|---|---|---|---|---|

| Classificação Temperatura/℃ | 1260 | 1260 | 1350 | 1430 | |

| Cor | Branco | Branco | Branco | Branco | |

| Densidade a granel (kg/m³) | 250/300/360 | 250/300/360 | 300/360 | 300/360 | |

| Módulos de rutura ≥/MPa | 0.3 | 0.3 | 0.3 | 0.3 | |

| Resistência à compressão/MPa (10% deformação relativa) | 0.15/0.25/0.3 | 0.25/0.3 | 0.25/0.3 | 0.25/0.3 | |

| Perda de ignição ≤/% | 6 | 6 | 6 | 6 | |

| Variação linear permanente ≤/% | 1000℃ x 24h 3.0 |

1100℃ x 24h 3.0 |

1200℃ x 24h 3.0 |

1350℃ x 24h 3.0 |

|

| Coeficiente de Condutividade Térmica /[W/(m-K)] | 400℃ | 0.08 | 0.07 | 0.07 | 0.07 |

| 600℃ | 0.11 | 0.1 | 0.1 | 0.09 | |

| 800℃ | 0.14 | 0.14 | 0.13 | 0.13 | |

| 1000℃ | 0.19 | 0.19 | 0.19 | 0.18 | |

Vantagens do painel de fibras cerâmicas

Leve

O painel de fibras cerâmicas tem baixa densidade, é fácil de manusear e tem elevada resistência. Isto torna-o mais fácil e mais flexível em várias aplicações e reduz a carga sobre a estrutura. Kerui Refractory irá fornecer-lhe as placas de fibra cerâmica da mais alta qualidade.

Aquecimento uniforme

A distribuição uniforme das fibras garante uma temperatura de aquecimento uniforme da superfície e reduz a tensão térmica. Isto ajuda a evitar fissuras e deformações causadas por diferenças de temperatura, melhorando a estabilidade e a durabilidade do produto.

Boa resistência

O painel de fibras cerâmicas tem uma certa capacidade de tração e não é fácil de partir. Isto permite a resistência ao impacto e ao stress mecânico durante a utilização, aumentando a durabilidade do produto. Bem-vindo a visitar a fábrica Kerui.

Elevada resistência à compressão

Pode suportar uma certa pressão e manter a integridade estrutural e a estabilidade. A placa de fibra cerâmica garante a fiabilidade e a segurança do produto durante a utilização. Tem uma longa vida útil.

Processo de fabrico do painel de fibras cerâmicas

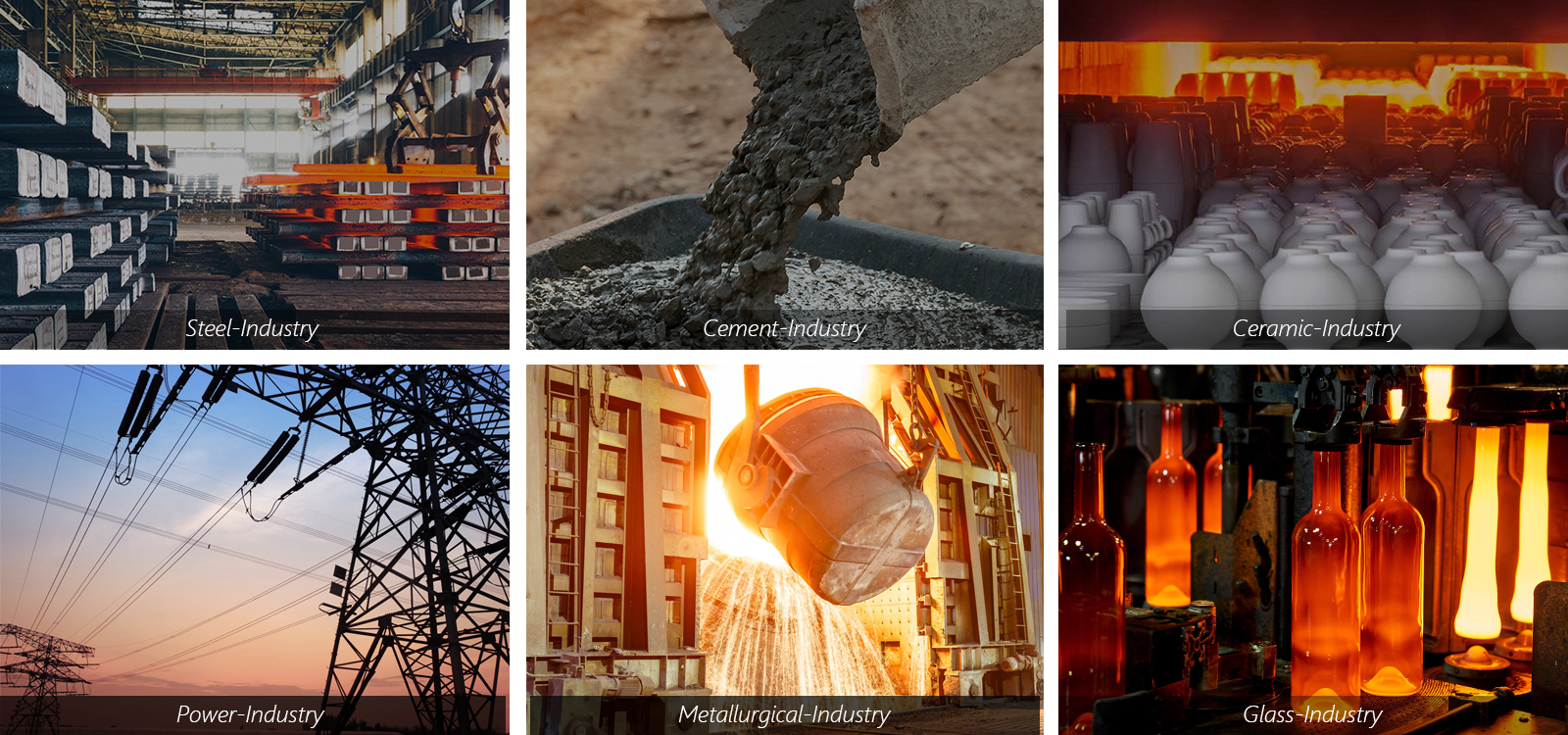

Aplicação do painel de fibras cerâmicas

Indústria metalúrgica

As placas de fibra cerâmica podem ser utilizadas para isolamento térmico e camadas de isolamento de equipamento de alta temperatura, como altos-fornos, fornos de produção de ferro, fornos de aço, células electrolíticas de alumínio e células electrolíticas de cobre.

Indústria petroquímica

Estrutura de revestimento de fibra cerâmica em camadas; revestimento de estrutura modular empilhada (dobrável); estrutura de revestimento de fibra cerâmica folheada; estrutura de revestimento de fibra cerâmica amorfa; estrutura de revestimento de estrutura composta.

Indústria da energia

As placas de fibra cerâmica podem ser usadas para isolamento térmico de caldeiras de usinas térmicas, chaminés, tubos e outros materiais de isolamento elétrico e equipamentos de alta temperatura. Bem-vindo a visitar a fábrica Kerui.

Indústria eletrónica

O painel de fibras cerâmicas pode ser utilizado na zona de isolamento de fornos de alta temperatura e outros equipamentos no fabrico de componentes electrónicos. Melhor placa de fibra cerâmica em Kerui Refractory.

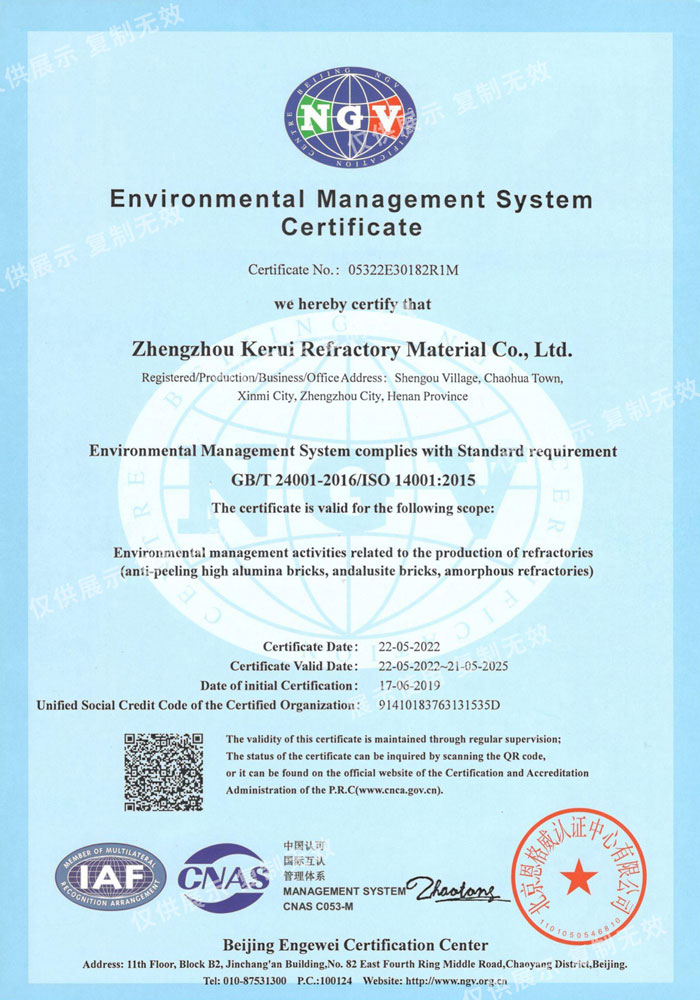

CERTIFICADOS DE REFRACTÁRIOS DE KERUI

O Grupo Kerui possui várias certificações internacionais, tais como, ISO9001/ISO14001/OHSAS18001/CE/SGS. Além disso, os produtos da Kerui também possuem muitos certificados nacionais, a qualidade é muito garantida e foram unanimemente reconhecidos pelos clientes no país e no exterior.

Laboratório de Refractários de Kerui

A Kerui possui um laboratório de inspeção de qualidade profissional. Forno de ensaio de fluência de reaquecimento/amaciamento de carga a alta temperatura; Banco de ensaio de resistência à compressão/flexão para materiais refractários; Plataforma de ensaio e inspeção da composição para materiais refractários; Laboratório de propriedades físicas/químicas para materiais refractários.

EMBALAGEM E ENVIO DE PRODUTOS REFRACTÁRIOS KERUI

Todo o processo de entrega é acompanhado e a equipa de especialistas da Kerui resolve as necessidades específicas do projeto com o máximo profissionalismo. Se o projeto do cliente o exigir, a equipa de especialistas da Kerui desloca-se ao país do cliente para prestar assistência técnica presencial.

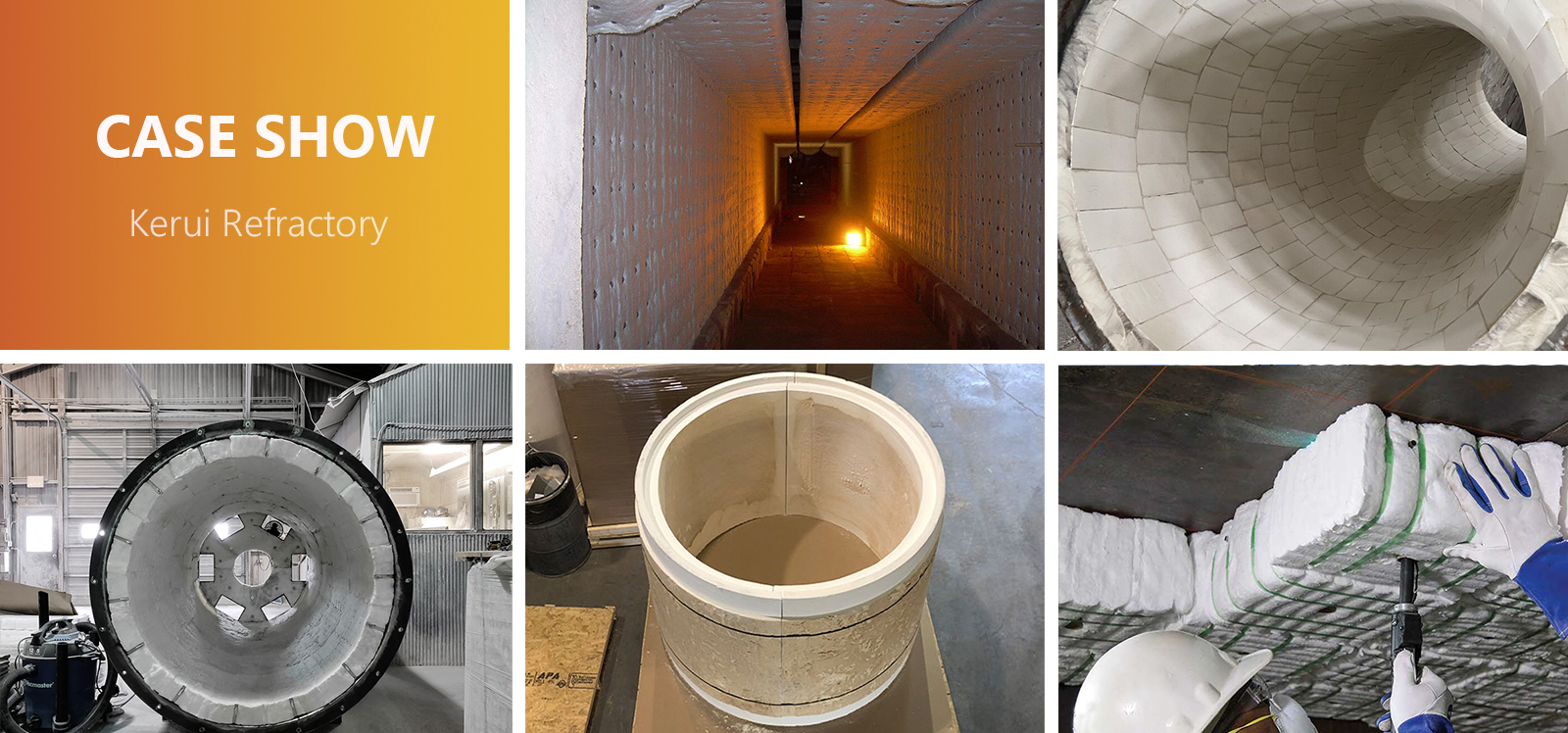

CASO DE CLIENTE DA KERUI REFRACTORY

Além da China continental, Kerui Refractory exportou produtos para mais de 50 países e regiões em 5 continentes em todo o mundo, incluindo Ásia, Europa, América, África e Oceania. Recebemos reconhecimento e elogios de clientes em todo o mundo, e estamos constantemente a receber pedidos de retorno e referências de clientes.