Briques réfractaires and refractory castables are the two most common refractory materials used in the design and operation of high-temperature industrial furnaces. They have different performance characteristics and applications, and choosing the right one directly impacts the furnace’s lifespan and operating costs.

1. The Difference Between Refractory Bricks and Refractory Castables

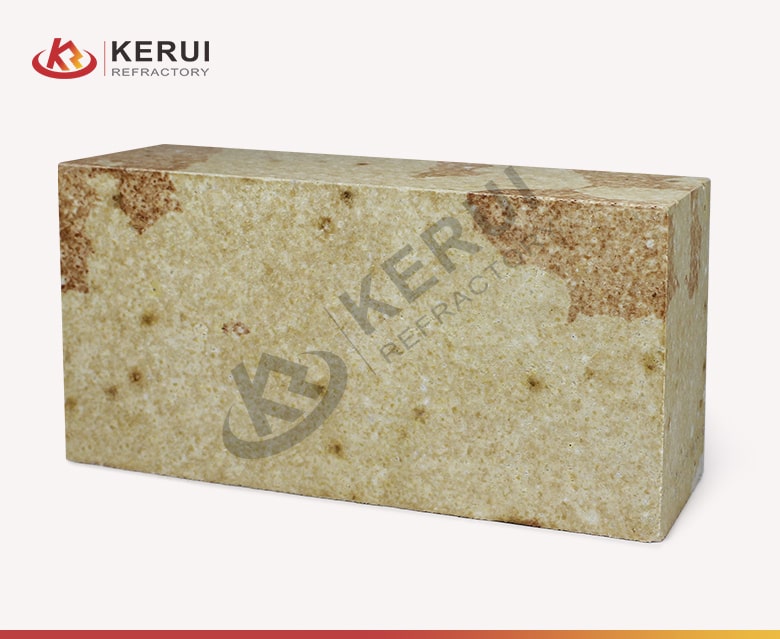

✅ Refractory Bricks (Shaped Refractory Materials)

Shape: Block or irregular shape, fixed dimensions

Advantages: High strength, wear resistance, easy installation

Applications: Areas subject to high mechanical impact, such as furnace walls, furnace floors, and furnace openings

✅ Refractory Castables (Unshaped Refractory Materials)

Shape: Powdered, poured after adding water and mixing on-site

Advantages: Good integrity, seamless, and adaptable to complex shapes

Applications: Complex structures such as vaults, furnace lining repairs, and ladle linings

2. Selection Principles

Select by Location

Intense erosion and wear → Use refractory bricks

Complex structures requiring integral casting → Use refractory castables

Select by Temperature

1700°C (High temperature stability required) → Use shaped bricks such as high-alumina bricks and magnesia bricks

<1700°C (High integrity required) → High-strength castables

Select based on construction and maintenance

Short construction period, limited construction conditions → Refractory brick masonry

Long lifespan, pursuit of integrity → Refractory castables

III. Typical Application Cases

Glass kiln bottom → High-alumina bricks/magnesia-chrome bricks, corrosion resistance, long lifespan

Cement rotary kiln head hood → High-strength refractory castables, convenient for integrated construction

Steel blast furnace taphole → Primarily refractory bricks, with localized castable repairs

IV. Summary and Recommendations

Regular areas → Bricks

Complex areas → Castables

High-temperature impact → Bricks are more reliable

Integral sealing → Castables are more suitable

The best practice is often to use a combination of “refractory bricks + castables,” flexibly matching them to different kiln locations to achieve a balance between durability and ease of construction.

KERUI Refractory supplies a variety of refractory bricks and refractory castables for use in high-temperature environments such as high-temperature kilns, high-temperature pipes, and boilers. Please contact us for any needs.