Ladrillo de corindón

- Al2O3/%: 95-98

- SiO2/%: 0,15-0,5

- Fe2O3/%: 0,1-0,3

- Refractariedad bajo carga: 1700MPa

- Resistencia al aplastamiento en frío: 80-100MPa

- Certificación: ISO9001/ISO14001/ISO45001/ISO50001

- Muestra: posibilidad de probar la muestra

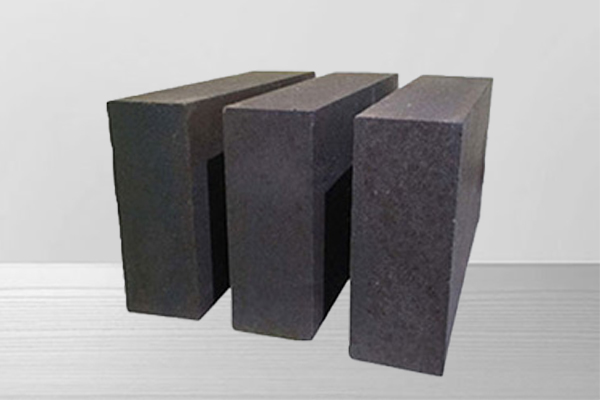

Descripción del ladrillo corindón

Los ladrillos de corindón son productos refractarios con corindón como fase cristalina principal, en los que el contenido de Al2O3 es superior a 90%. Alta resistencia a la compresión a temperatura normal (hasta 340MPa). Alta temperatura de inicio de reblandecimiento de la carga (superior a 1700°C). Buena estabilidad química, fuerte resistencia a la escoria ácida o alcalina, al metal y al líquido de vidrio. La estabilidad al choque térmico está relacionada con su estructura, la resistencia a la corrosión de los productos densos es buena, pero la estabilidad al choque térmico es mala. Hay dos tipos de ladrillos de corindón sinterizado y ladrillos de corindón fundido. Pueden fabricarse utilizando alúmina sinterizada y corindón fundido como materias primas, o clinker de bauxita con alta relación Al2O3/SiO2 y alúmina sinterizada, y se fabrican por el método de sinterización. Los ladrillos de corindón sin cocer también pueden fabricarse con ácido fosfórico u otros aglutinantes.

Clasificación de los ladrillos de corindón

Corindón Mullita Ladrillo

El material principal del ladrillo de mullita de corindón es corindón de placa importado, corindón fundido de alta pureza, adopta tecnología avanzada de adición de polvo superfino, se fabrica mediante la mezcla de material, secado, moldeado y quemado en horno de lanzadera de alta temperatura.

Ladrillo de corindón fundido

Los ladrillos de corindón fundido se fabrican fundiendo alúmina en un horno de arco eléctrico y moldeándola en un modelo determinado con una forma específica. El producto deseado se obtiene mediante recocido y mantenimiento, y después se procesa con abrasivos diamantados.

Ladrillo de corindón cromado

El ladrillo de corindón al cromo también se denomina ladrillo de machaqueo de corindón al cromo de alta resistencia al desgaste. Utilizando α-Al2O3 como materia prima, se añade la cantidad adecuada de polvo de cromo y polvo fino de clinker de cromo corindón, y después se les da forma y se queman a alta temperatura. La composición mineral principal es solución sólida de α-Al2O3-Cr2O3. Los minerales menores consisten en una pequeña cantidad de espinela compuesta (o sin espinela compuesta), ladrillos refractarios con un contenido de óxido de cromo de 1% a 30%.

OBTENER PRECIO

Ladrillo con alto contenido en cromo

Los ladrillos de alto contenido en cromo se fabrican con óxido de cromo y alúmina como materias primas principales, o se introduce una pequeña cantidad de óxido de circonio. Después de la cocción a alta temperatura en. El contenido de óxido de cromo no es inferior a 75%, y el contenido de óxido de cromo y alúmina no es inferior a 98% de los productos refractarios conformados. Los ladrillos de alto contenido en cromo tienen una excelente resistencia a la lixiviación, una elevada resistencia a la compresión a temperatura ambiente, una excelente resistencia al desgaste, resistencia a altas temperaturas, buena resistencia al choque térmico, etc.

OBTENER PRECIO

Ficha técnica de Kerui Corundum Brick

| Artículo/Grado | GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 | |

|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 99.0 | 99.0 | 98.0 | 95.0 |

| ở | 0.30 | ||||

| ω (SiO2)/% | μ0 ≤ | 0.15 | 0.2 | 0.5 | / |

| ở | 0.08 | ||||

| ω (Fe2O3)/% | μ0 ≤ | 0.10 | 0.15 | 0.2 | 0.3 |

| ở | 0.03 | ||||

| Porosidad aparente/% | μ0 ≤ | 19 | 19 | 19 | 20 |

| ở | 1 | ||||

| Densidad aparente (g/cm³) | μ0 ≤ | 3.20 | 3.15 | 3.15 | 3.1 |

| ở | 0.05 | ||||

| Resistencia al aplastamiento en frío/MPa | μ0 ≥ | 80 | 80 | 80 | 100 |

| ở | 15 | ||||

| Cambio lineal permanente (1600℃*3h)/% | Xmin Xmax |

-0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 |

| 0,2MPa 0,6% Refractariedad Subcarga/℃ | Xmin | 1700 | 1700 | 1700 | 1700 |

Ventajas del ladrillo de corindón

Alta dureza

El ladrillo de corindón tiene una dureza muy elevada, la dureza del ladrillo de corindón se aproxima a la dureza Mohs 9, que es más dura que el acero.

Resistencia a la corrosión

Los ladrillos de corindón presentan una gran resistencia a la corrosión frente a diversos ácidos, álcalis y soluciones químicas, y pueden funcionar de forma estable en entornos químicos agresivos.

Resistencia a altas temperaturas

El grado de ablandamiento de la carga de los ladrillos de corindón suele estar entre 1600-1800 grados, y su temperatura refractaria puede alcanzar entre 1770-2000 grados.

Estabilidad dimensional

Los ladrillos de corindón tienen buena resistencia al choque térmico, y la refractariedad no es inferior a 1690 grados. Su coeficiente de dilatación lineal entre 20-450 grados es de aproximadamente 0,03 mm/deg, por lo que puede soportar la presión estática del flujo de fusión a alta temperatura sin romperse.

Excelente rendimiento de aislamiento

El ladrillo de corindón es un excelente material aislante, que puede bloquear la corriente y la conducción del calor, y es adecuado para aplicaciones de aislamiento eléctrico y aislamiento térmico a alta temperatura.

Buena permeabilidad al aire

el gas precipitado en la masa fundida del ladrillo de corindón de circonio puede penetrar por los huecos de las partículas de arena de sílice de la pared de moldeo, por lo que la permeabilidad al aire es buena.

Aplicación del ladrillo de corindón

Se utiliza en altos hornos de fabricación de hierro y altos hornos calientes, hornos de refinado externo de fabricación de acero, calentadores de agua deslizantes, hornos de fusión de vidrio y hornos industriales petroquímicos.