SK34 Firebrick

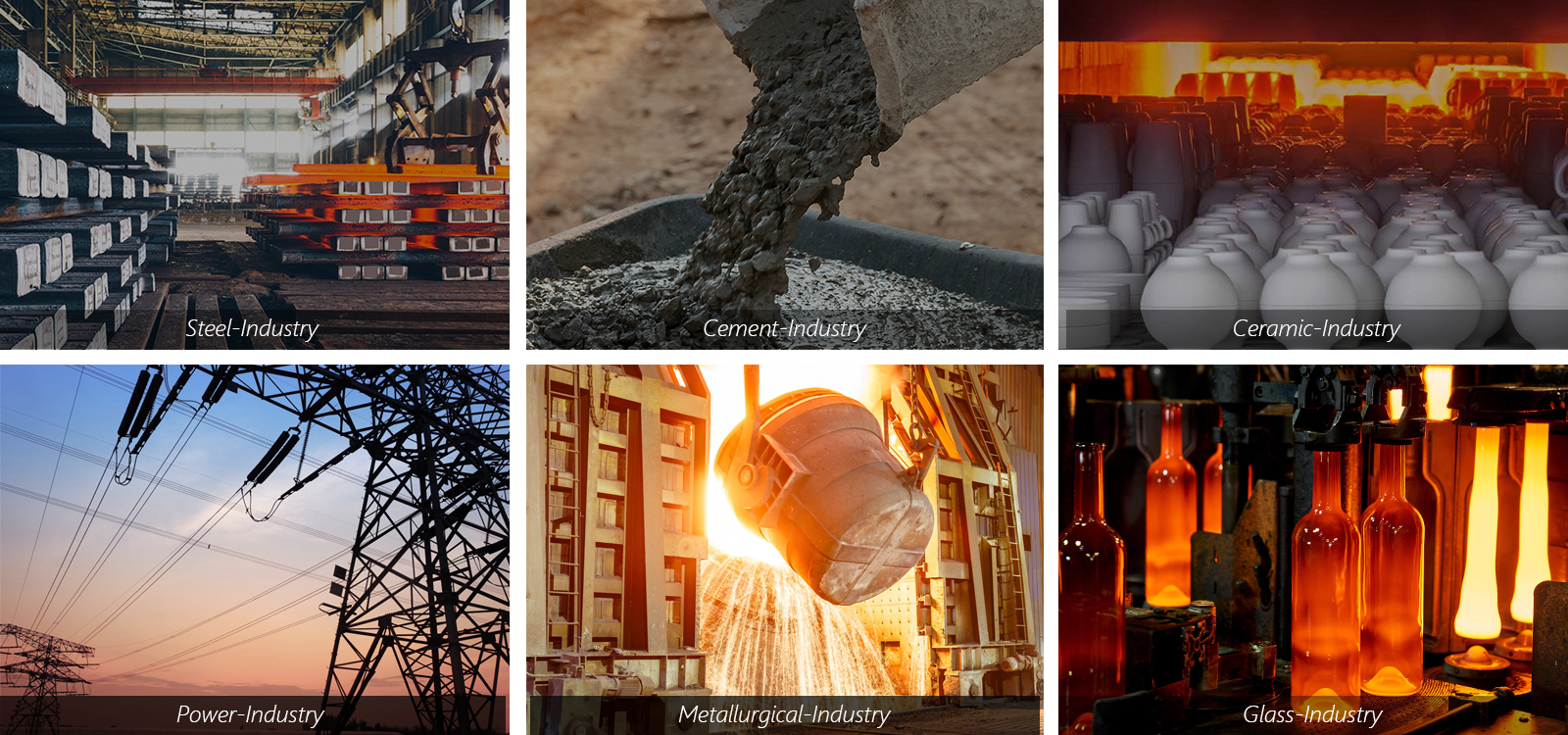

Used for various high – temperature industrial furnaces, such as those in the metallurgical and ceramic industries.

- Al2O3:%≥ 38%;

- Fe2O3, % ≤: 2;

- Refractoriness, ≥: 1730;

- Bulk Density , g/cm3: 2.1-2.2;

- Certification: ISO9001/ISO14001/ISO45001/ISO50001;

- Sample: available;

Description of SK34 Firebrick

SK34 Firebrick is a high quality Clay refractory brick. It typically has a yellowish color and a standard cuboid shape, often with dimensions like 230×114×65mm. Classified as a Fire Clay Brick, it contains at least 38% Al₂O₃ and no more than 2% Fe₂O₃. This chemical composition gives it excellent chemical stability and resistance to slag.

With a bulk density of 2.1 – 2.2g/cm³ and an apparent porosity of ≤20% – 22%, it has low thermal conductivity, reducing heat loss effectively. Its cold compressive strength is ≥30MPa, enabling it to withstand mechanical stress. Moreover, it can endure high temperatures up to 1770 – 1800℃, making it suitable for use in various high – temperature industrial furnaces, such as those in the metallurgical and ceramic industries.

We supply SK series refractory bricks. According to export standards, SK30/32/34 are clay bricks, and SK36~40 are high-alumina bricks. Specific specifications can be customized. Welcome to inquire at any time!

Technique Data of Kerui SK34 Firebrick

| Index | SK34 Firebrick |

|---|---|

| Al2O3 ,%≥ | 42 |

| Fe2O3, % ≤ | 2 |

| Compressive Strength , MPa≥ | 25 |

| Refractoriness, ≥ | 1730 |

| Apparent Porosity, % ≤ | 24 |

| Bulk Density , g/cm3 | 2.1-2.2 |

| Reheat line change,% 1400×2h | +0.1~ -0.5 |

| 0.2Mpa refractoriness under load, ≥ | 1350 |

Advantages of SK34 Firebrick

High refractoriness

It can withstand temperatures ranging from 1770℃ to 1800℃, and its load – softening temperature under 0.2MPa is not less than 1360℃. This makes it suitable for use in high – temperature industrial furnaces and kilns.

Good Chemical Stability

With an Al₂O₃ content of not less than 38% and an Fe₂O₃ content of not more than 2%, it has good chemical stability and slag resistance. It can resist the erosion of various chemical substances, ensuring its performance and service life in harsh chemical environments.

Low Thermal Conductivity

The firebrick has a low thermal conductivity, which helps to effectively reduce heat transfer. This not only improves the thermal efficiency of the furnace but also reduces energy consumption and heat loss to the outside, playing a role in energy conservation and environmental protection.

High Mechanical Strength

The firebrick has a low thermal conductivity, which helps to effectively reduce heat transfer. This not only improves the thermal efficiency of the furnace but also reduces energy consumption and heat loss to the outside, playing a role in energy conservation and environmental protection.

Excellent Volume Stability

SK34 firebrick has a low creep rate at high temperatures, which means it has good volume stability. It can maintain its original shape and size during long – term high – temperature use, reducing the risk of furnace damage caused by brick deformation.

Application of SK34 Firebrick

SK34 Firebrick is widely used in various high – temperature industrial applications. It is commonly employed in metallurgical furnaces, such as blast furnaces and steel – making furnaces. It is also used in ceramic kilns and glass – melting furnaces, where it helps to withstand high temperatures and protect the furnace structure.