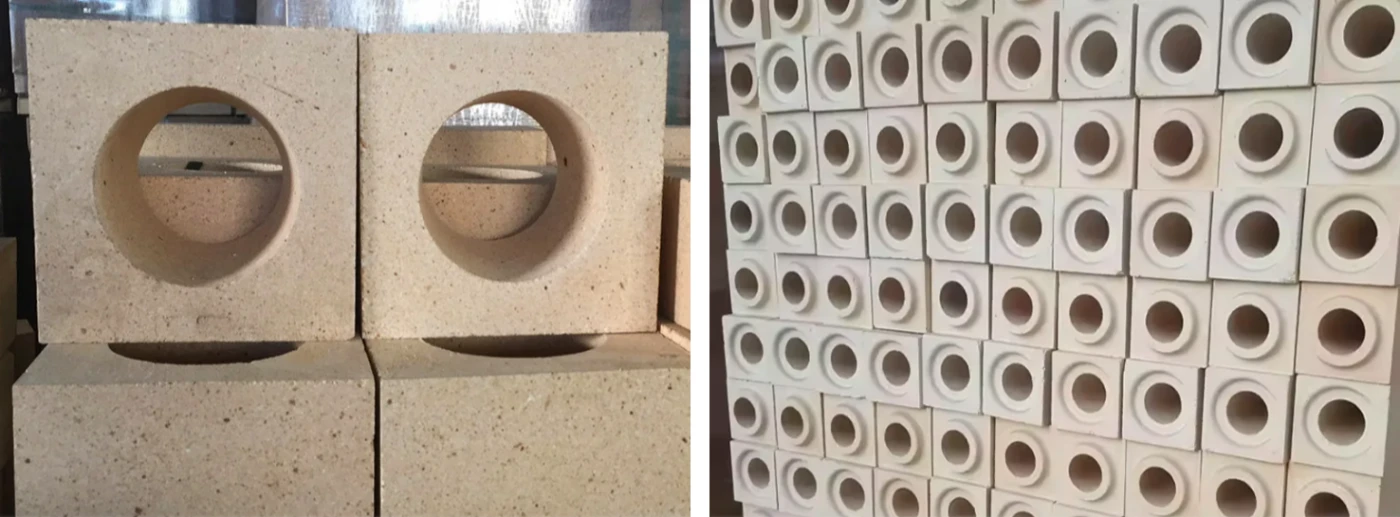

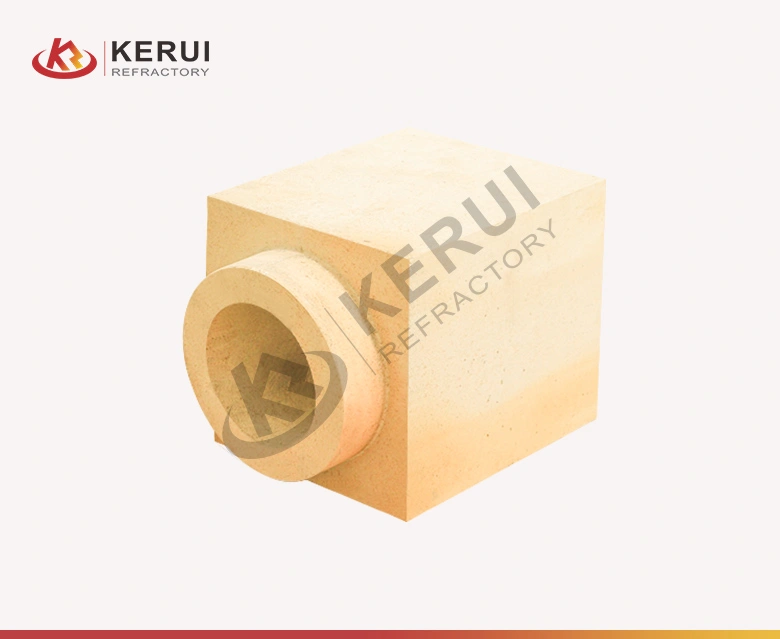

坑井ブロック耐火物の説明

耐火物ウェルブロックは、鉄鋼業の連続鋳造プロセスで重要な役割を果たします。厳選された耐火物から作られるため、過酷な条件にも耐えることができます。ウェルブロック耐火物は、主にハイアルミナ、マグネシアアルミニウムスピネル、耐火性キャスタブルなどの材料で作られています。特定の耐火性は、さまざまな用途の要件に応じて原材料の組成と割合を変更することによって調整することができます。例えば、アルミナ含有量が高いウェルブロック耐火物は、一般に耐火度が高い。

Kerui坑井ブロック耐火物の技術データ

| 違い | ツンディッシュ・ウェル・ブロック | レードル・ウェル・ブロック |

|---|---|---|

| 所在地 | タンディッシュの底 | お玉の底 |

| 主要機能 | 金型への溶鋼の流量を制御し、鋼材の清浄度を向上させます。 | 炉から取鍋への溶鋼流量を制御し、場合によっては鋼組成を調整する。 |

| オペレーティング・ステージ | 連続鋳造プロセス | 製鋼とティーム加工 |

| カテゴリー | 技術仕様 | 説明 |

|---|---|---|

| 寸法 | 230×114×76mm(標準) | 炉の設計に応じてカスタマイズ可能、公差±2 mm |

| 素材タイプ | 高アルミナ質耐火レンガ(Al₂O₃≧48%) | オプション:標準ハイアルミナ、マグネシアアルミナ、ジルコンレンガなど。 |

| 密度 | 2.2-2.6 g/cm³ | 高密度レンガは耐摩耗性に優れ、低密度レンガは断熱性に優れる。 |

| 吸水 | ≤ 6% | 低吸水性により耐久性が向上 |

| 圧縮強度 | ≥ 80 MPa | 高温下でも耐荷重性を維持 |

| 曲げ強度 | ≥ 20 MPa | 熱応力や機械的衝撃に強い |

| 屈折率 | 1600-1800 ℃ | 軟化したり割れたりしない |

| 耐熱衝撃性 | ≥ 20サイクル | 加熱と冷却を繰り返してもクラックが発生しない |

| 熱伝導率 | 1.0-2.0 W/m-K | 断熱と熱伝導を選択可能 |

| 化学組成 | Al₂O₃:48-60%, SiO₂:30-45%、Fe₂O₃≦2%、CaO+MgO≦3% | 酸性/アルカリ性は要件に応じて調整可能 |

| 発射条件 | 完全焼結 | 強度と耐久性を高める |

| 表面精度 | 平坦度 ≤ 1.0 mm | 施工精度を確保し、隙間を減らす |

ウェルブロック耐火物の利点

優れた耐熱性

最高1770~2000℃の超高温に耐えることができるため、製鋼炉やガラス溶解釜のような高熱環境での使用に適している。

卓越した化学的安定性

工業プロセスにおける酸性媒体、アルカリ性媒体を問わず、様々な物質による化学腐食に耐性があります。この特性は、化学プラントや石油化学リアクターでの長期間の使用を保証します。

高い機械的強度

機械的応力、摩耗、熱衝撃に耐える十分な強度を持つ。そのため、セメントロータリーキルンのような温度変化や機械的衝撃が頻繁に起こる設備でも、構造的完全性を維持することができる。