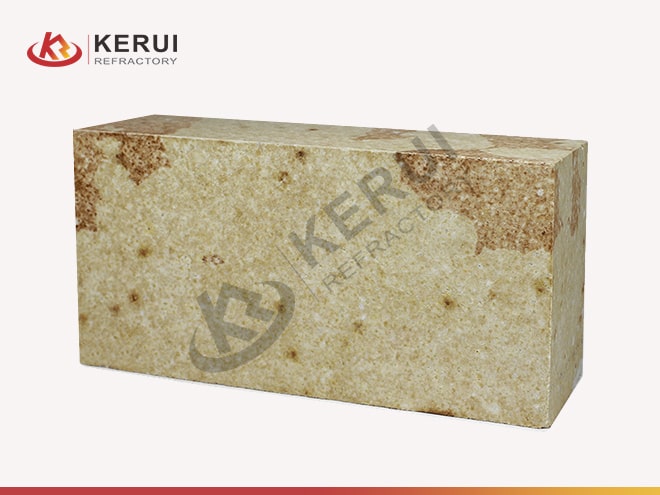

- MgO%≧:70/75/80 ZrO2 %≧:8/10/13;

- 見掛け気孔率%≦19;

- かさ密度(g/cm3)≥:2.95;

- 荷重屈折率:≥1600 °C

- 嵩密度 g/cm3:≥ 3.15;

- 冷間破砕強度 (Mpa)≥90;

- 見掛け気孔率(%):≦17;

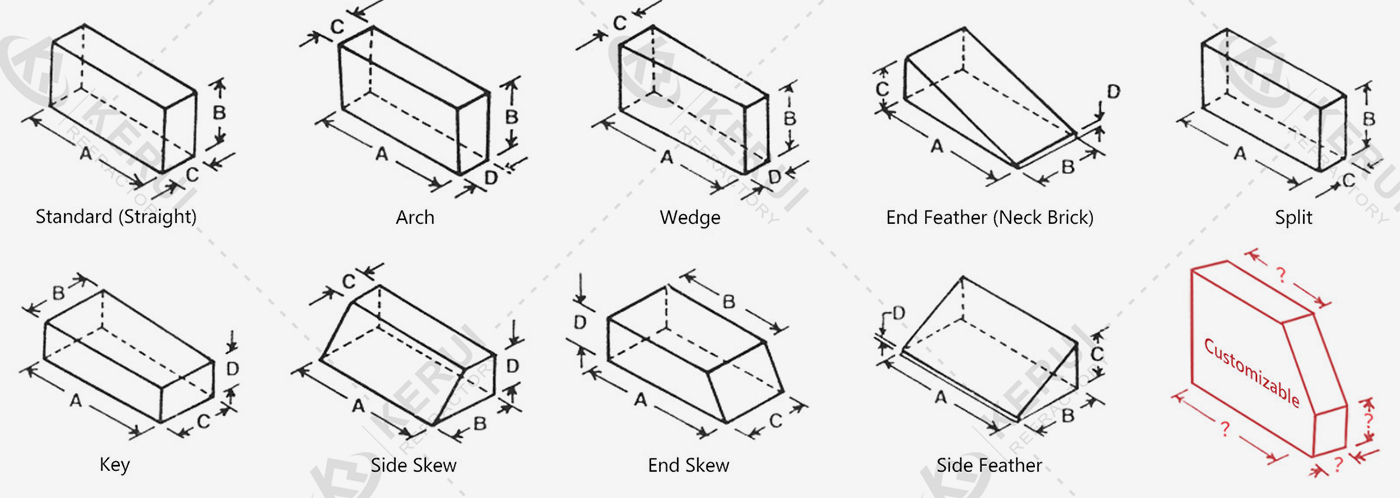

- サイズ: 230*114*65mm; カスタマイズされたサイズ

- 嵩密度 g/cm3:≥ 3.15;

- 冷間破砕強度 (Mpa)≥90;

- 見掛け気孔率(%):≦17;

- サイズ: 230*114*65mm; カスタマイズされたサイズ

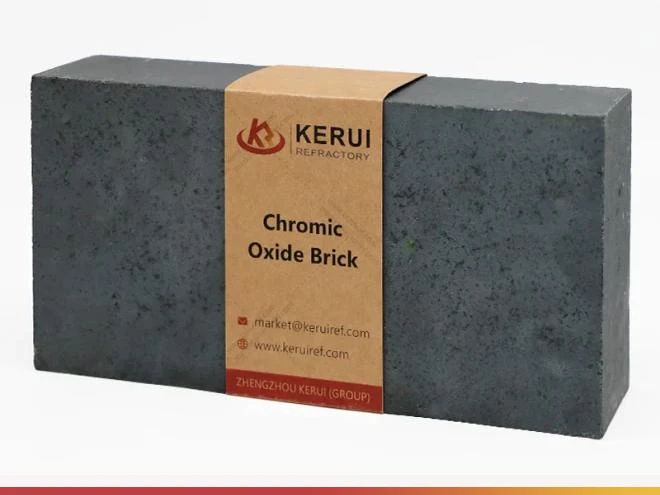

- 嵩密度 g/cm3: ≥3.25;

- 見掛け気孔率 %: ≤15;

- 耐圧強度(Mpa)≧1800;

- 負荷柔らかくなる温度(0.2Mpa T0.6 ℃): ≥168;

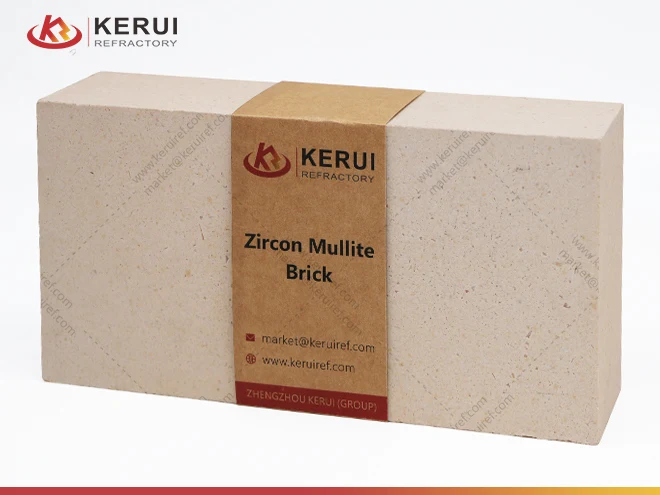

- Refractoriness: ≥1730-1810℃;

- Al2O3: ≥55-80%;

- Bulk Density: 2.15-2.8g/cm³;

- サンプル:あり;

カスタマイズされた耐火レンガ

Keruiの耐火物の工場は顧客の要求に従っていろいろな種類の定形レンガをカスタマイズすることができる。当社は自社工場を持ち、研究開発チーム、技術チーム、生産チームを持っています。さらに、私達にまた各市場に精通している専門の販売のチームおよびサービス チームがあります。従って照会への歓迎!

Kerui耐火レンガの用途

焼結炉およびキルン

焼結炉およびキルン耐火レンガは、セラミックス、セメント、石灰、鉱石などの焼結炉や窯の建設によく使われる。高温に長時間耐えることができる。

ガラス炉

ガラス炉ガラス製造業では、ガラス原料を溶かすために高温を必要とするガラス炉の建設に耐火レンガが使用される。

鉄鋼製錬

鉄鋼製錬鉄鋼業界では、耐火レンガは、高温や化学的攻撃に耐えるために、高炉、転炉、電気アーク炉、その他の製錬設備の建設に使用されている。

石炭ガス化炉と化学工業

石炭ガス化炉と化学工業耐火レンガは、石炭ガス化炉、化学反応炉、その他の化学工業用途にも使用される。これらの炉は高温と腐食性化学薬品に耐える必要があるからだ。

工業用高温炉本体

工業用高温炉本体耐火レンガは、高温製錬炉、焼却炉、ガラス炉、鉄鋼炉などの工業炉体の製造によく使用される。

石炭ガス化炉と化学工業

石炭ガス化炉と化学工業耐火レンガは、石炭ガス化炉、化学反応炉、その他の化学工業用途にも使用される。これらの炉は高温と腐食性化学薬品に耐える必要があるからだ。

耐火レンガの製造工程

私達は専門の技術的なチームおよび生産設備が付いている私達の自身の工場を持っています。

全自動バッチシステム、20セットの400-1000トン成形プレス、2 * 168mの高温トンネルキルン、20000㎡の貯蔵作業場。

製品の品質を確保し、生産効率を向上させ、顧客に最も満足のいく製品とサービスを提供する。

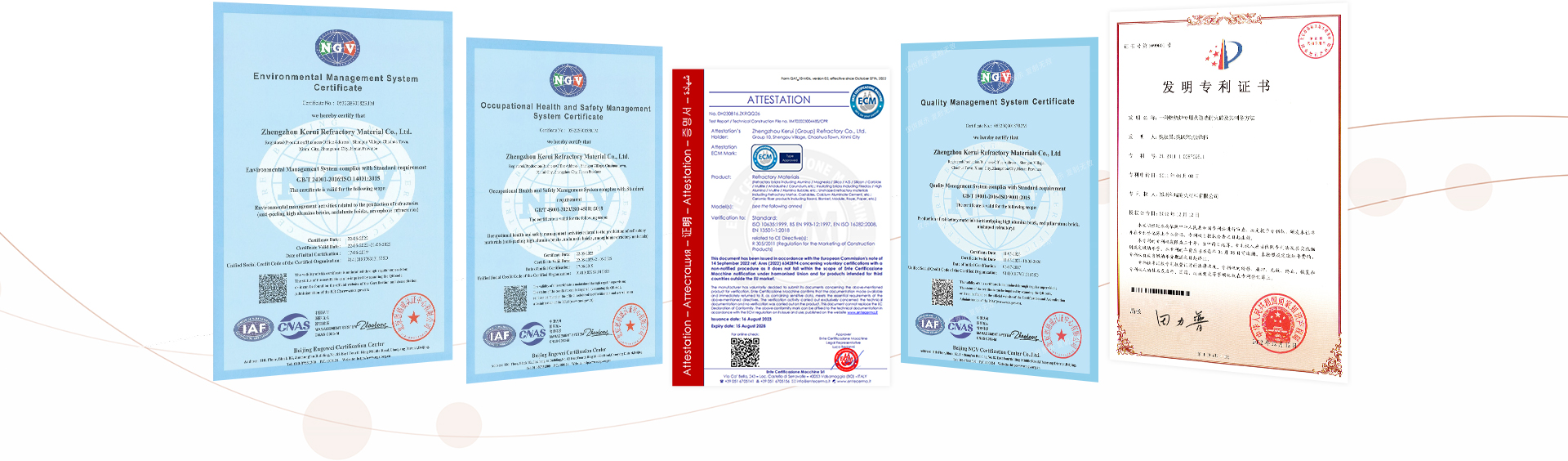

ケルイ耐火物の証明書

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides,

Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

耐火物製品の梱包と出荷

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism.

If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

ケルイ耐火物のお客様事例

中国本土以外にも、アジア、ヨーロッパ、アメリカ、アフリカ、オセアニアなど世界5大陸の50以上の国と地域に製品を輸出しています。

世界中のお客様から高い評価を得ており、リピートオーダーやご紹介も絶えません。

-

5大陸

-

50+各国

-

1700+成功事例

-

4500+お客様