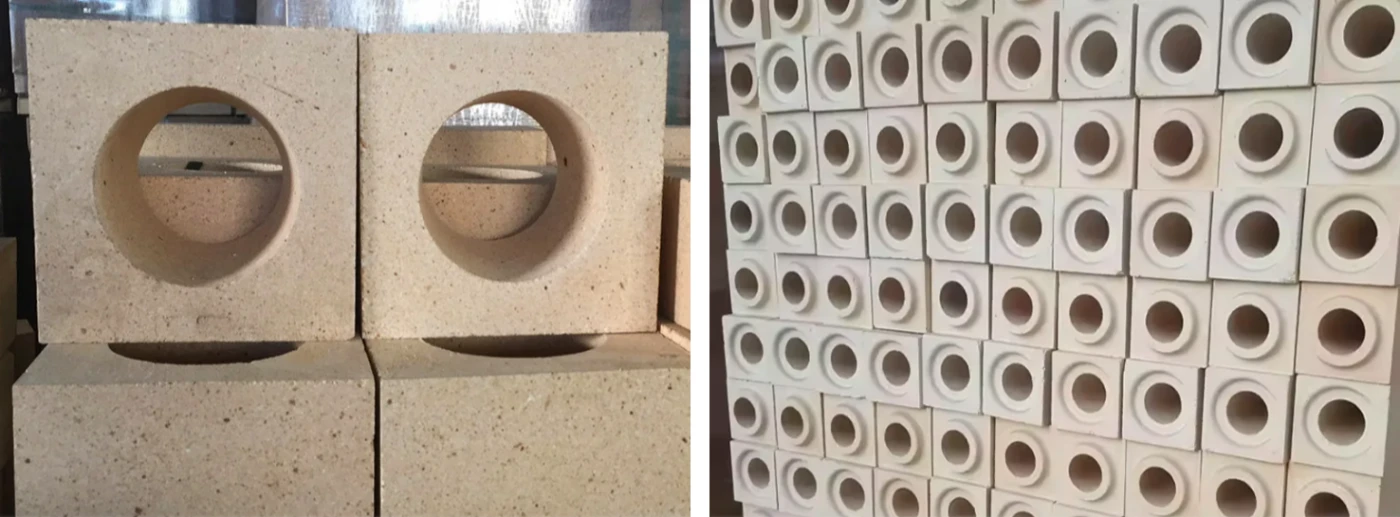

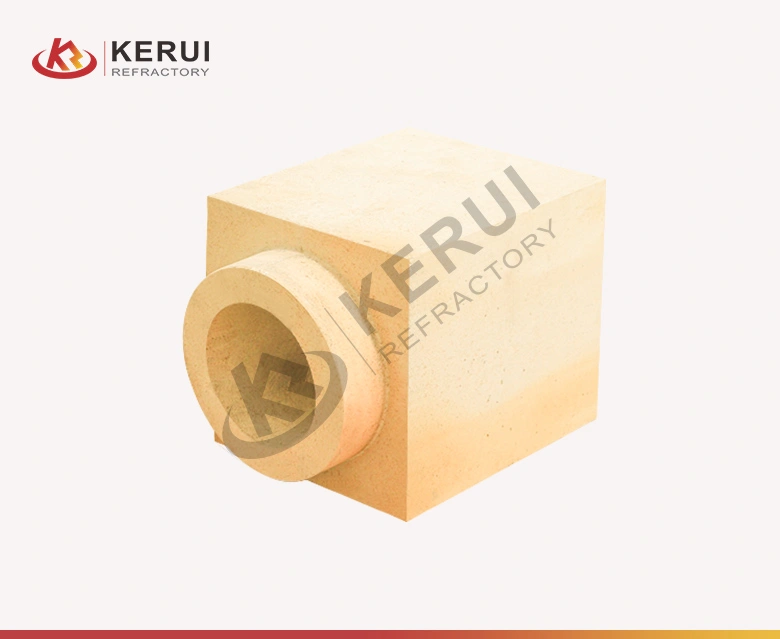

Bloque de pozo Refractario

El refractario de bloque de pozo tiene múltiples aplicaciones:

En metalurgia, reviste cazos y artesas, protegiéndolos del elevado calor del metal fundido.

En la producción de cemento, se utiliza en hornos rotatorios para resistir el calor y la corrosión química.

En la fabricación de vidrio, protege los hornos de fusión. Su resistencia al calor y su durabilidad lo hacen vital para estos procesos industriales a altas temperaturas.

Descripción del bloque del pozo Refractario

Los bloques refractarios para pozos desempeñan un papel fundamental en el proceso de colada continua de la industria siderúrgica. Fabricados con materiales refractarios cuidadosamente seleccionados, son capaces de soportar condiciones extremas. Los bloques refractarios se componen principalmente de materiales como la alúmina, la magnesia, la espinela de aluminio y los hormigones refractarios. La refractariedad específica puede ajustarse cambiando la composición y la proporción de las materias primas según los distintos requisitos de aplicación. Por ejemplo, los refractarios de bloque de pozo con un mayor contenido de alúmina suelen tener una mayor refractariedad.

Datos técnicos del bloque de pozos refractarios de Kerui

| Diferencia | Bloque de pozos de Tundish | Bloque de pozo |

|---|---|---|

| Ubicación | Fondo de la artesa | Fondo del cazo |

| Función principal | Controla el caudal de acero fundido en el molde y mejora la limpieza del acero | Controla el caudal de acero fundido del horno a la cuchara y, en algunos casos, ajusta la composición del acero. |

| Fase operativa | Proceso de colada continua | Proceso de fabricación del acero |

| Categoría | Especificaciones técnicas | Descripción |

|---|---|---|

| Dimensiones | 230 × 114 × 76 mm (estándar) | Personalizable según el diseño del horno, tolerancia ±2 mm |

| Tipo de material | Ladrillo refractario de alta alúmina (Al₂O₃ ≥ 48%) | Opciones: ladrillos estándar de alto contenido en alúmina, magnesia-alúmina, circón, etc. |

| Densidad | 2,2-2,6 g/cm³ | Los ladrillos de alta densidad son más resistentes al desgaste; los ladrillos de baja densidad son más aislantes. |

| Absorción de agua | ≤ 6% | La menor absorción de agua mejora la durabilidad |

| Resistencia a la compresión | ≥ 80 MPa | Mantiene la capacidad de carga a altas temperaturas |

| Resistencia a la flexión | ≥ 20 MPa | Resistente al estrés térmico y a los impactos mecánicos |

| Refractariedad | 1600-1800 ℃ | No se ablanda ni se agrieta |

| Resistencia al choque térmico | ≥ 20 ciclos | No se agrieta bajo calentamiento y enfriamiento repetidos |

| Conductividad térmica | 1,0-2,0 W/m-K | Seleccionable para aislamiento o conducción del calor |

| Composición química | Al₂O₃: 48-60%, SiO₂: 30-45%, Fe₂O₃ ≤ 2%, CaO+MgO ≤ 3%. | Propiedades ácidas/alcalinas ajustables según las necesidades |

| Condición de disparo | Totalmente sinterizado | Aumenta la resistencia y la durabilidad |

| Precisión de la superficie | Planitud ≤ 1,0 mm | Garantiza la precisión de la construcción y reduce las lagunas |

Ventajas de Well Block Refractory

Excepcional resistencia al calor

Puede soportar temperaturas extremadamente altas, a menudo de hasta 1770 - 2000°C, lo que lo hace adecuado para su uso en entornos de calor intenso, como hornos de fabricación de acero y ollas de fusión de vidrio.

Excelente estabilidad química

Resistente a la corrosión química de diversas sustancias, ya sean los medios ácidos o alcalinos de los procesos industriales. Esta propiedad garantiza un servicio a largo plazo en plantas químicas y reactores petroquímicos.

Alta resistencia mecánica

Tiene resistencia suficiente para soportar tensiones mecánicas, abrasión y choques térmicos. Esto le permite mantener su integridad estructural en equipos con frecuentes fluctuaciones de temperatura e impactos mecánicos, como los hornos rotatorios de cemento.