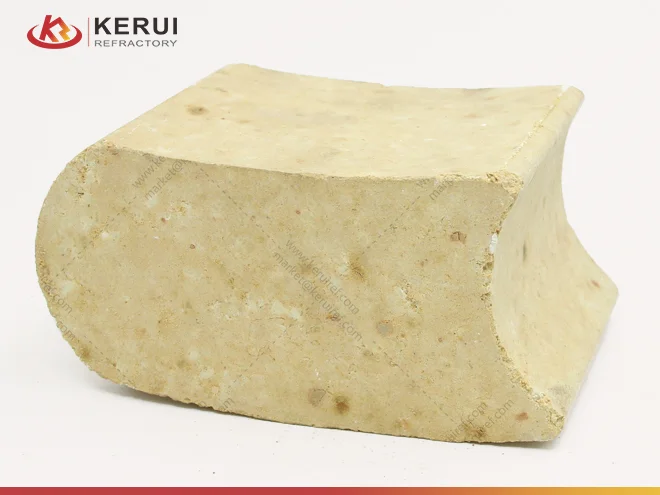

Ladrillo refractario curvo

- Porosidad aparente, %: ≤26;

- Resistencia al aplastamiento en frío, MPa: ≥40;

- Buena resistencia a la corrosión;

- Buena resistencia al desconchamiento y al desgaste;

- Certificación: ISO9001/ISO14001/ISO45001/ISO50001;

- Muestra: disponible;

Descripción del ladrillo refractario curvo

El ladrillo refractario curvado es un ladrillo común de diseño semicircular y forma especial, generalmente de alta alúmina o arcilla, con buena resistencia al fuego. Se utiliza principalmente para el revestimiento de equipos resistentes a altas temperaturas, como hornos industriales y calderas. Los ladrillos curvados pueden soportar temperaturas de hasta 1400°C o superiores.

Debido a la forma especial de los ladrillos curvos, es adecuado para hogares circulares o estructuras curvas. Se utiliza mucho en operaciones a alta temperatura, como la siderurgia y los hornos de cerámica.

Datos técnicos de los ladrillos refractarios curvados Kerui

| Artículo | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-60 | LZ-55 | LZ-48 | |

|---|---|---|---|---|---|---|---|---|

| Al2O3, /% | ≥ | 80 | 75 | 70 | 65 | 60 | 55 | 48 |

| Porosidad aparente, % | ≤ | 21 | 24 | 24 | 24 | 26 | 22 | 22 |

| Resistencia al aplastamiento en frío, MPa | ≥ | 70 | 60 | 55 | 50 | 45 | 45 | 40 |

| 0,2MPa Refractariedad bajo carga, ℃ | ≥ | 1530 | 1520 | 1510 | 1500 | 1430 | 1450 | 1420 |

| Cambio lineal permanente, % | 1500℃*2h-0.4~0.2 | 1450℃*2h-0.4~0.1 | ||||||

Tipos de ladrillos refractarios curvos

Los ladrillos refractarios curvados pueden clasificarse en función de sus materiales, formas y usos. A continuación se exponen los principales métodos de clasificación:

▶ Clasificación por materiales:

1.Ladrillos refractarios de arcilla: hechos principalmente de arcilla, adecuados para entornos con temperaturas no superiores a 1300°C.

2.Ladrillos refractarios de alta alúmina: contienen una mayor proporción de bauxita, tienen una alta refractariedad y son adecuados para aplicaciones a temperaturas más elevadas.

3.Ladrillos refractarios de magnesio: utilizan mineral de magnesio como materia prima, tienen una excelente resistencia a la corrosión y se utilizan a menudo en la fundición de metales.

4.Ladrillos refractarios de sílice: compuestos principalmente de dióxido de silicio, adecuados para ambientes ácidos.

▶ Clasificación por formas

1.Ladrillos curvos estándar: tienen un diseño semicircular estándar y son adecuados para estructuras generales de hornos.

2.Ladrillos curvados especiales: incluyen una variedad de formas no estándar, como ranuras o diseños angulares especiales, para adaptarse a estructuras de horno específicas.

Clasificación por uso

1.Ladrillos curvados para altos hornos: especialmente diseñados para revestimientos de altos hornos, resisten temperaturas extremadamente altas y la erosión química.

2.Ladrillos curvados para hornos eléctricos: utilizados para revestimientos de hornos eléctricos, destacando el aislamiento eléctrico y la estabilidad térmica.

3.Ladrillos curvados para hornos de cemento: Diseñados para necesidades especiales en el proceso de producción de cemento.