Ladrillo de corindón cromado

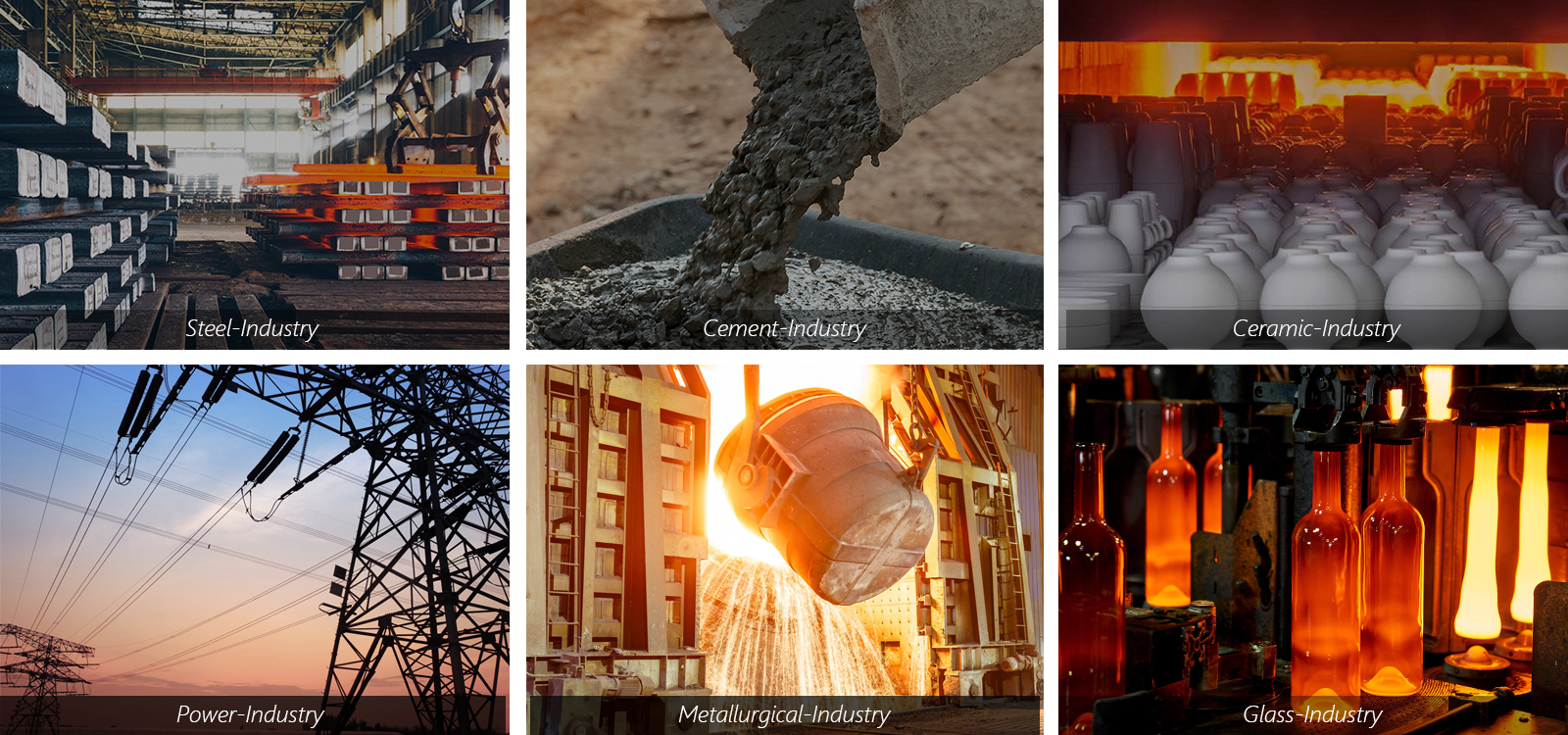

Se utiliza en hornos siderúrgicos y hornos de refinado en la industria metalúrgica, hornos de vidrio en la industria del vidrio y hornos de alta temperatura en la industria cerámica.

- Densidad aparente g/cm3: ≥3,25;

- Porosidad aparente %: ≤15;

- Resistencia a la presión(Mpa)≥1800;

- Temperatura de reblandecimiento de la carga(0,2Mpa T0,6 ℃): ≥168;

- Certificación: ISO9001/ISO14001/ISO45001/ISO50001;

- Muestra: disponible;

Descripción del ladrillo de corindón cromado

Los ladrillos de corindón al cromo se fabrican a partir de α-Al2O3 como materia prima, a la que se añade una cantidad adecuada de polvo de óxido de cromo y polvo fino de clinker de corindón al cromo, y a continuación se forman y cuecen a alta temperatura. La composición mineral principal es α-Al2O3-Cr2O3 solución sólida, el mineral secundario se compone de una pequeña cantidad de espinela compuesta (o sin espinela compuesta), y el contenido de óxido de cromo es de 1% a 30% de los ladrillos refractarios.

Datos técnicos del ladrillo de cromo corindón Kerui

| Ladrillo de cromo corindón fundido | KR-G92-Cr | |

|---|---|---|

| Composición química(%) | Al2O3 | ≥92 |

| SiO2 | ≤1.0 | |

| Fe2O3 | ≤0.3 | |

| CaO | ≤1.2 | |

| Na2O | - | |

| ZrO2 | ≥3 | |

| Cr2O3 | ≥3 | |

| Porosidad aparente (%) | ≤15 | |

| Densidad aparente(g/cm3) | ≥3.25 | |

| Resistencia a la presión(Mpa) | ≥180 | |

| Resistencia a la flexión a alta temperatura(1250℃ Mpa) | ≥9.5 | |

| Refractariedad(℃) | ≥1900 | |

| Temperatura de reblandecimiento de la carga(0,2Mpa T0,6 ℃) | ≥1680 | |

| Tasa de cambio de la línea de combustión % (1500℃×2h) | ≤±1.2 | |

Ventajas del ladrillo de corindón al cromo

Los ladrillos de cromo corindón se caracterizan por su gran dureza, excelente resistencia al desgaste, buena resistencia al choque térmico y resistencia a altas temperaturas. También tienen una gran estabilidad química y una baja conductividad térmica, lo que garantiza un rendimiento fiable en entornos hostiles de altas temperaturas.

Aplicación del ladrillo de corindón al cromo

- Industria metalúrgica:horno siderúrgico, horno de refinado, etc;

- Industria del vidrio: horno de vidrio;

- Industria cerámica: horno de alta temperatura, que puede resistir la erosión y la socavación a alta temperatura y aumentar la vida útil del horno.