الأسمنت عالي الألومينا

- النوع: CA50/CA70/CA70/CA80

- آل2O3%: 50-81

- الدقة (d50/ميكرومتر): 5-13

- قوة الانضغــــاط/م بيسكال (24 ساعة) 30-72

- الشهادات: ISO9001/ISO14001/ISO45001/ISO50001

- العينة: اختبار العينة متاح

وصف الأسمنت عالي الألومينا

الأسمنت عالي الألومينا (المعروف سابقاً باسم أسمنت البوكسيت) هو مادة أسمنتية هيدروليكية تحتوي على الألومينات كمكون معدني رئيسي، يتم تحضيره بواسطة البوكسيت والجير بنسبة معينة، ويتم تكليسه وطحنه، ويعرف أيضاً باسم أسمنت الألومينات. يتميز بخصائص حرارية استثنائية، بما في ذلك مقاومة درجات الحرارة العالية، ومقاومة ممتازة للصدمات الحرارية، وانكماش منخفض في درجات الحرارة المرتفعة. تم تصميم هذا الأسمنت خصيصاً للتطبيقات في البيئات ذات درجات الحرارة العالية مثل بطانات الأفران وبطانات الأفران وغيرها من المنشآت المقاومة للحرارة. يوفر سرعة التماسك والتصلب السريع، ويحقق قوة مبكرة عالية، ويظهر مقاومة جيدة للهجوم الكيميائي، مما يجعله مناسباً للبيئات الحمضية.

بيانات تقنية الأسمنت عالي الألومينا من كيروي

| الصنف/الرتبة | CA50 | CA70 | CA80 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A600 | A700 | A900 | CA70 | CA70W | CA70S | CA71 | CA80 | CA80S | |||

| التركيب الكيميائي | ω (SiO2) ≤/% | 7.8 | 7.5 | 5.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| ω (Al2O3)/% | 50.0 | 51.0 | 53.5 | 68.5-70.5 | 68.5-70.5 | 68.5-70.5 | 69.5-71.5 | 78.0-81.0 | 78.0-81.0 | ||

| ω (Fe2O3) ≤/% | 2.5 | 2.5 | 2.5 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | ||

| ω (CaO) / % | / | / | / | 28.5-30.5 | 28.5-30.5 | 28.5-30.5 | 27.5-29.5 | 17.5-20.5 | 17.5-20.5 | ||

| ω (MgO) ≤/% | / | / | / | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | ||

| ω (R2O) ≤/% | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | ||

| ω (S) ≤/% | 0.1 | 0.1 | 0.1 | / | / | / | / | / | / | ||

| ω (Cl) ≤/% | 0.1 | 0.1 | 0.1 | / | / | / | / | / | / | ||

| النقاء | د50/م50/م | / | / | / | 11-4 | 8-11 | 6-9 | 10-13 | 5-8 | 5-8 | |

| -45 ميكرومتر ≤ / % | / | / | / | 8.0 | 5.0 | 5.0 | 8.0 | 5.0 | 5.0 | ||

| ضبط الوقت | وقت الإعداد الأولي (دقيقة) | ≥45 | ≥60 | ≥90 | 120-180 | 30-90 | 180-240 | 150-210 | 30-90 | 90-150 | |

| وقت الإعداد النهائي (دقيقة) | ≤360 | ≤360 | ≤360 | 150-240 | 90-180 | 240-330 | 210-300 | 90-180 | 270-360 | ||

| القوة (ISO) | قوة الانحناء/ميجا باسكال | 24h | 6.0 | 6.5 | 8.0 | 7.5-10.0 | 8.0-10.5 | 8.0-10.5 | 8.5-11.0 | 5.0-7.5 | 5.0-7.5 |

| 72h | 7.0 | 7.5 | 10.0 | 10.0-12.0 | 10.5-12.5 | 10.5-12.5 | 11.0-12.5 | 6.0-8.5 | 6.0-8.5 | ||

| قوة الضغط/ميجا باسكال | 24h | 45 | 55 | 72 | 40-50 | 45-55 | 45-55 | 50-60 | 30-40 | 30-40 | |

| 72h | 55 | 65 | 82 | 45-55 | 50-60 | 50-60 | 55-65 | 40-50 | 40-50 | ||

| 325 م ≤/% | 15 | 12 | 8 | / | / | / | / | / | / | ||

| مساحات السطح المحددة ≥/ (㎡/كجم) | 300 | 320 | 350 | / | / | / | / | / | / | ||

بالإضافة إلى ذلك، نوفر أيضًا: أسمنت CA40/41

مميزات الأسمنت عالي الألومينا

حرارة الترطيب الكبيرة

يطلق الأسمنت المتصلب المبكر الكثير من الحرارة. بالمقارنة مع الأسمنت البورتلاندي من نفس الدرجة، يمكنه إطلاق 70-80% من الحرارة الكلية للترطيب في يوم واحد فقط. ونظراً لإطلاقه الكثير من الحرارة، فهو مناسب لأعمال الخرسانة ذات درجة الحرارة المنخفضة للمعالجة. وباعتبارها أفضل مورد في الصين، يمكن لـ Kerui تزويد العملاء بمنتجات عالية الجودة.

مقاومة قوية لتآكل الكبريتات

هيكل الحجر الأسمنتي للأسمنت عالي الألومينا كثيف، والمكون الرئيسي هو ألومينات الكالسيوم المنخفضة، ومحتوى أكسيد الكالسيوم صغير جدًا. أثناء عملية الترطيب، لا يتم ترسيب هيدروكسيد الكالسيوم الحر ولكن يتم تشكيل هلام هيدروكسيد الألومنيوم. تتشكل طبقة واقية على سطح الجسيمات.

مقاومة جيدة لدرجات الحرارة العالية

سيحافظ دائمًا على حالته الصلبة في بيئة ذات درجة حرارة عالية، ولن تتغير قوة الأسمنت. يمكن استخدام الأسمنت عالي الألومينا كمادة إسمنتية للخرسانة المقاومة للحرارة وتكوينها في الخرسانة المقاومة للحرارة. مرحباً بكم في زيارة مصنع كيروي للحصول على عرض أسعار مجاني.

خصائص القوة المبكرة

معدل زيادة قوته في وقت مبكر أعلى بكثير من معدل زيادة قوة الأسمنت البورتلاندي سريع التصلب، وهو مناسب لمشاريع الإصلاح الطارئة، ولكن قوته ستنخفض لاحقًا، واستخدامه في الهندسة الإنشائية محدود. ستوفر لك Kerui حلولاً احترافية ومنتجات عالية الجودة.

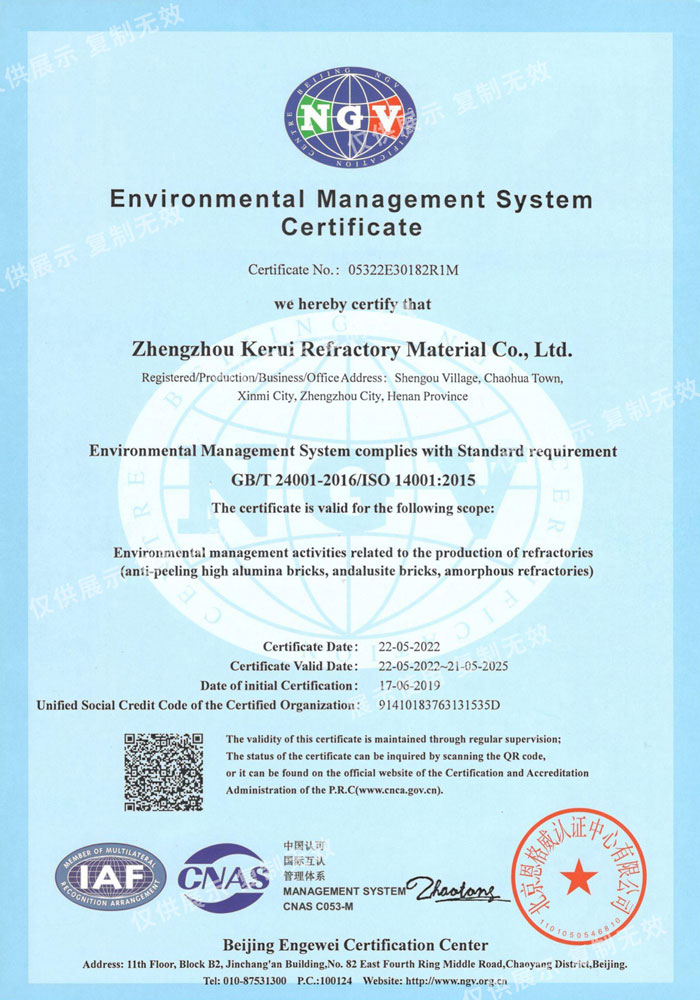

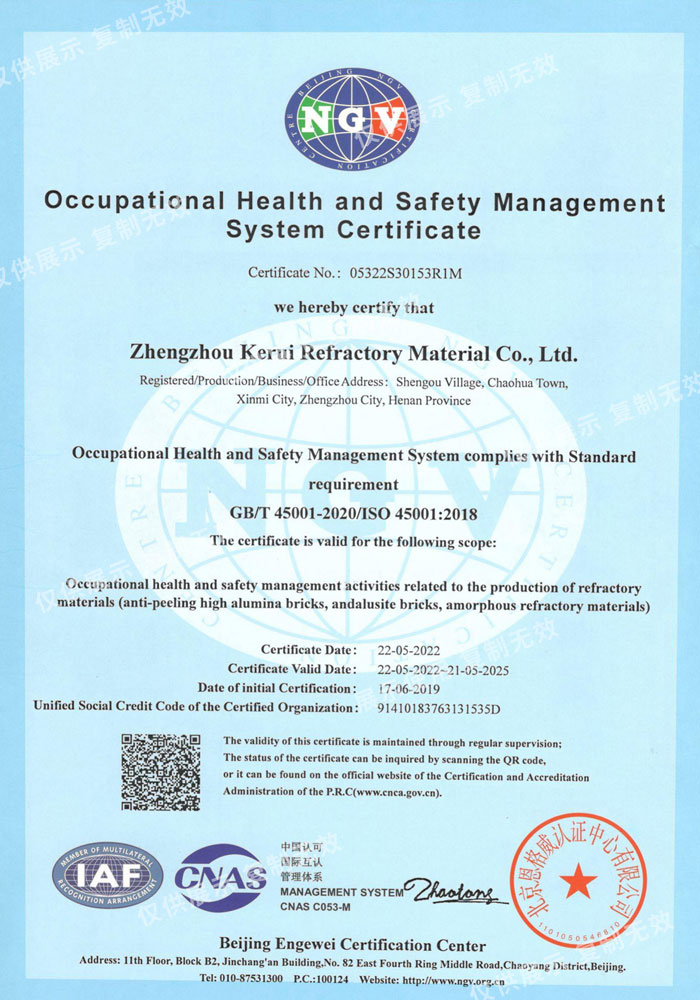

شهادات حراريات الكيروي الحرارية

حصلت مجموعة كيروي على عدد من الشهادات الدولية، مثل, ISO9001/ISO14001/OHSAS18001/CE/SGS. إلى جانب ذلك، تتمتع منتجات Kerui أيضًا بالعديد من الشهادات المحلية، والجودة مضمونة للغاية، وقد تم الاعتراف بها بالإجماع من قبل العملاء في الداخل والخارج.

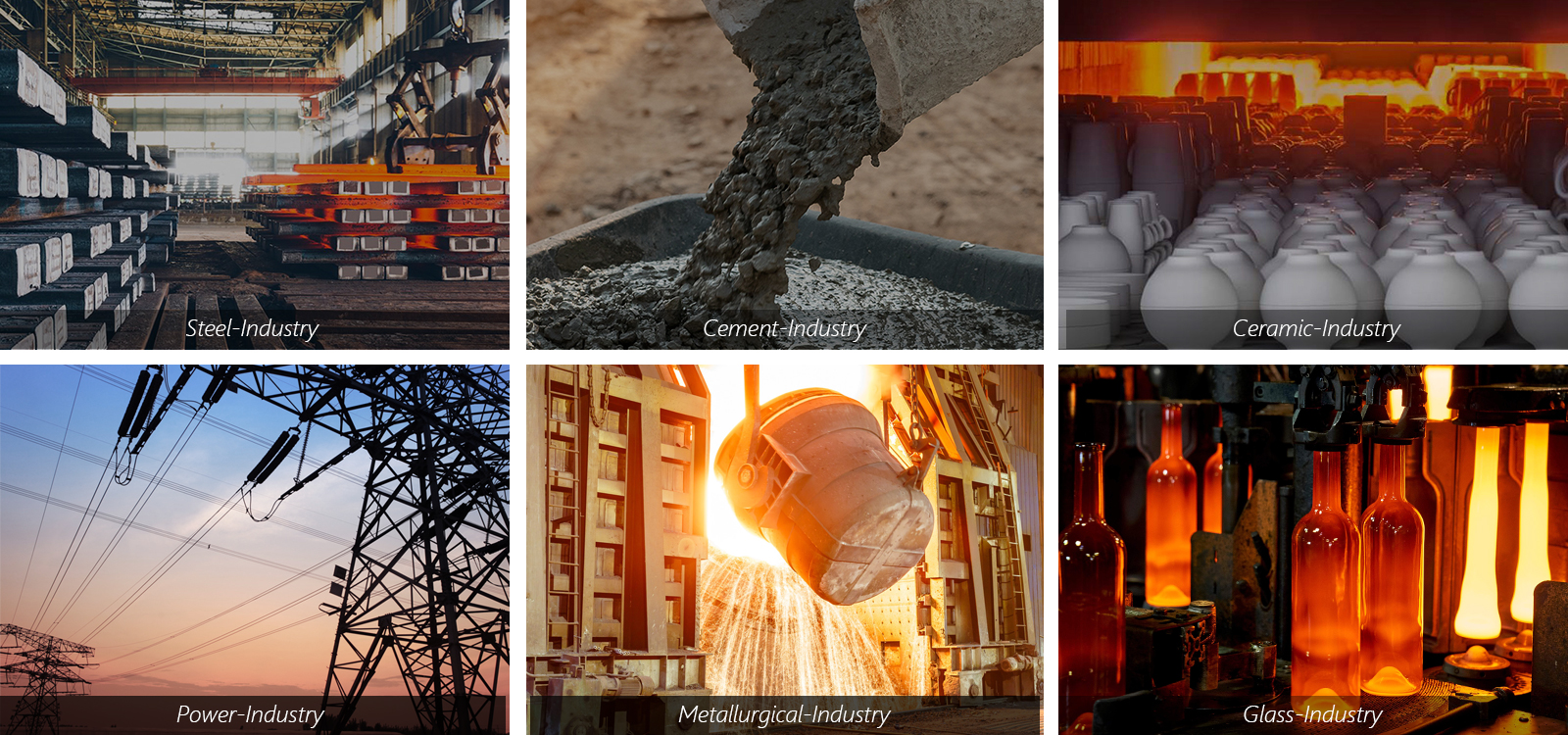

استخدام الأسمنت عالي الألومينا

مختبر كيروي للصهر الحراري

لدى Kerui مختبر فحص الجودة الاحترافي. فرن اختبار إعادة التسخين بدرجة حرارة عالية/فرن اختبار التليين الزاحف؛ ومقعد اختبار قوة الانضغاط/المرونة للمواد المقاومة للحرارة؛ ومنصة اختبار وفحص التركيب للمواد المقاومة للحرارة؛ ومختبر للخصائص الفيزيائية/الكيميائية للمواد المقاومة للحرارة.

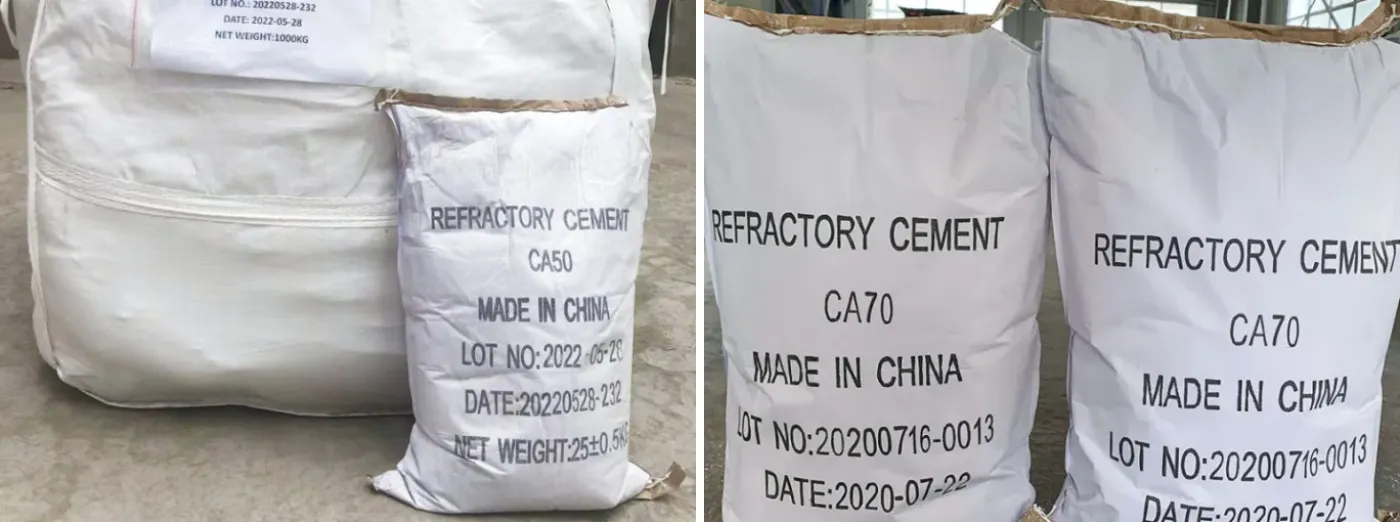

منتجات الحراريات الحرارية من كيروي للتغليف والشحن

يتم تتبع عملية التسليم بأكملها، ويقوم فريق خبراء Kerui بحل احتياجات المشروع المحددة بأقصى قدر من الاحترافية. وإذا كان مشروع العميل يتطلب ذلك، يذهب فريق خبراء Kerui إلى بلد العميل لتقديم الدعم الفني وجهاً لوجه.

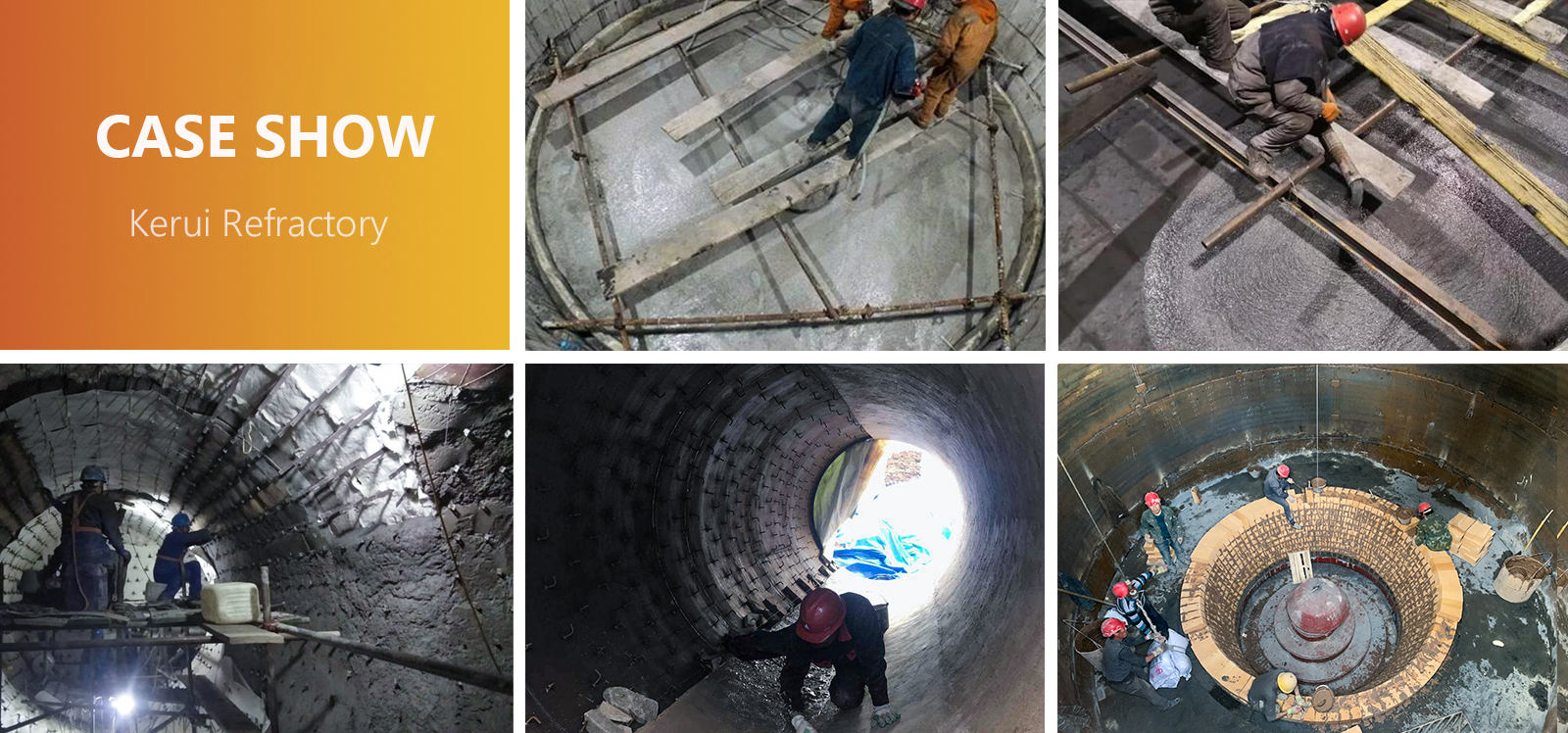

حالة عميل كيروي الحراري

إلى جانب البر الرئيسي للصين، قامت شركة Kerui Refractory بتصدير منتجاتها إلى أكثر من 50 دولة ومنطقة عبر 5 قارات في جميع أنحاء العالم، بما في ذلك آسيا وأوروبا وأمريكا وأفريقيا وأوقيانوسيا. وقد تلقينا تقديرًا وثناءً كبيرًا من العملاء في جميع أنحاء العالم، ونتلقى باستمرار طلبات إعادة العملاء وإحالاتهم.