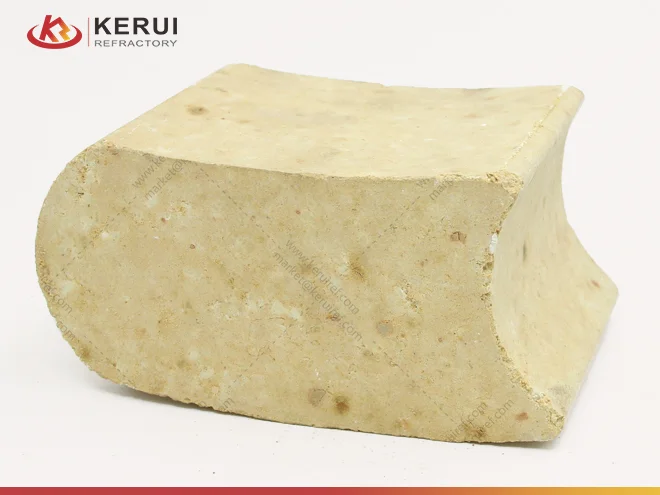

قرميد النار المنحني

- المسامية الظاهرة، %: ≤26;

- قوة التكسير على البارد، ميجا باسكال: ≥40;

- مقاومة جيدة للتآكل;

- مقاومة جيدة للتشقق ومقاومة التآكل;

- الشهادة: ISO9001/ISO14001/ISO45001/ISO50001;

- العينة: متاحة;

وصف قرميد النار المنحني

القرميد الحراري المنحني هو قرميد شائع نصف دائري التصميم خاص الشكل، وعادةً ما يكون مصنوعًا من الألومينا العالية أو الطين، ويتميز بمقاومة جيدة للحريق. ويستخدم بشكل أساسي لتبطين المعدات المقاومة للحرارة العالية مثل الأفران الصناعية والغلايات. يمكن أن يتحمل الطوب المنحني درجات حرارة تصل إلى 1400 درجة مئوية أو أعلى.

نظرًا للشكل الخاص للطوب المنحني، فهو مناسب للمداخن الدائرية أو الهياكل المنحنية. ويستخدم على نطاق واسع في عمليات درجات الحرارة العالية مثل صناعة الصلب وأفران السيراميك.

بيانات تقنية قرميد النار المنحني من كيروي

| البند | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-60 | LZ-55 | LZ-48 | |

|---|---|---|---|---|---|---|---|---|

| Al2O3, /% | ≥ | 80 | 75 | 70 | 65 | 60 | 55 | 48 |

| المسامية الظاهرة، % | ≤ | 21 | 24 | 24 | 24 | 26 | 22 | 22 |

| قوة التكسير على البارد، ميجا باسكال | ≥ | 70 | 60 | 55 | 50 | 45 | 45 | 40 |

| 0.2 ميجا باسكال انكسار تحت الحمل، ℃ | ≥ | 1530 | 1520 | 1510 | 1500 | 1430 | 1450 | 1420 |

| التغيير الخطي الدائم، % | 1500℃*2h-0.4~0.2 | 1450℃*2h-0.4~0.1 | ||||||

أنواع طوب الحريق المنحني

يمكن تصنيف الطوب الحراري المنحني وفقًا لمواده وأشكاله واستخداماته. وفيما يلي طرق التصنيف الرئيسية:

▶ Classification by Material:

1.Clay Refractory Bricks: mainly made of clay, suitable for environments with temperatures not exceeding 1300°C.

2.High Alumina Refractory Bricks: contain a higher proportion of bauxite, have high refractoriness, and are suitable for higher temperature applications.

3.Magnesium Refractory Bricks: use magnesium ore as raw material, have excellent corrosion resistance, and are often used in metal smelting.

4.Silica Refractory Bricks: mainly composed of silicon dioxide, suitable for acidic environments.

▶ Classification by Shape

1.Standard Curved Bricks: have a standard semicircular design and are suitable for general furnace structures.

2.Special Curved Bricks: include a variety of non-standard shapes, such as grooves or special angle designs, to adapt to specific furnace structures.

▶ Classification by Use

1.Curved bricks for blast furnaces: specially designed for blast furnace linings, withstand extreme high temperatures and chemical erosion.

2.Curved bricks for electric furnaces: used for electric furnace linings, emphasizing electrical insulation and thermal stability.

3.Curved bricks for cement kilns: Designed for special needs in the cement production process.