قرميد كروم اكسيد الالمونيوم

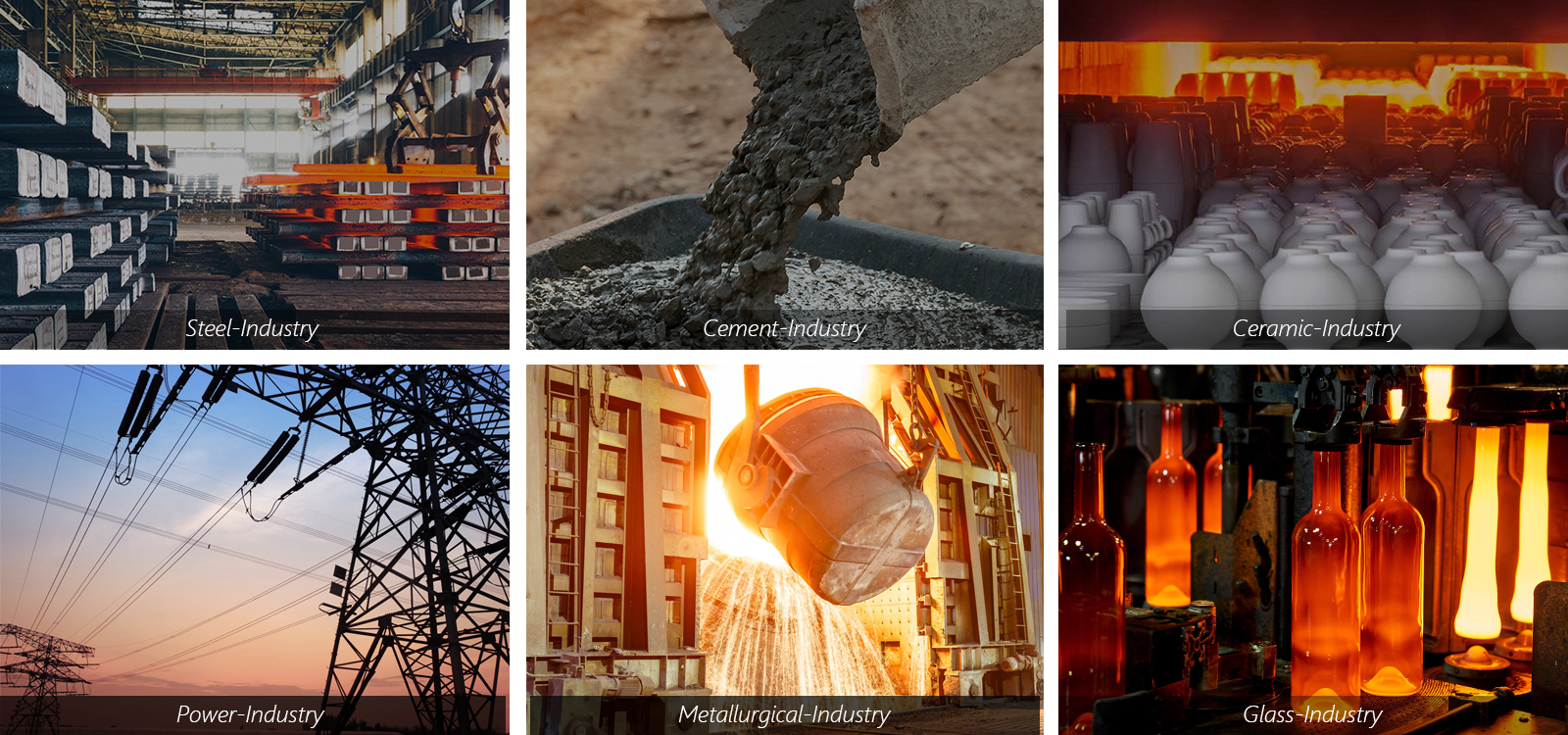

تُستخدم في أفران صناعة الصلب وأفران التكرير في صناعة المعادن، وأفران الزجاج في صناعة الزجاج، والأفران عالية الحرارة في صناعة السيراميك.

- الكثافة السائبة جم/سم3: ≥3.25;

- المسامية الظاهرة %: ≤15;

- قوة الضغط (Mpa) 1800;

- درجة حرارة تليين الحمل (0.2 ميجا باسكال T0.6 ℃): ≥168;

- الشهادة: ISO9001/ISO14001/ISO45001/ISO50001;

- العينة: متاحة;

وصف قرميد الكروم اكسيد الالمونيوم

يصنع قرميد اكسيد الكروم من α-Al2O3 كمادة خام، مع إضافة كمية مناسبة من مسحوق أكسيد الكروم ومسحوق كلنكر اكسيد الكروم الناعم، ثم يتم تشكيله وحرقه في درجة حرارة عالية. التركيب المعدني الرئيسي هو محلول α-Al2O3-Cr2O3 الصلب، ويتكون المعدن الثانوي من كمية صغيرة من الإسبنيل المركب (أو لا يوجد إسبنيل مركب)، ومحتوى أكسيد الكروم هو 1% إلى 30% من الطوب الحراري.

البيانات التقنية لطوب كروي كروم اكسيد الالمونيوم كيروي

| قرميد الكروم الكروم المصهور | KR-G92-Cr | |

|---|---|---|

| التركيب الكيميائي (%) | Al2O3 | ≥92 |

| SiO2 | ≤1.0 | |

| حديد2أكسيد الحديد2O3 | ≤0.3 | |

| ثاني أكسيد الكالسيوم | ≤1.2 | |

| Na2O | - | |

| ZrO2 | ≥3 | |

| Cr2O3 | ≥3 | |

| المسامية الظاهرة (%) | ≤15 | |

| الكثافة السائبة (g/cm3) | ≥3.25 | |

| قوة الضغط (ميجا باسكال) | ≥180 | |

| قوة الانثناء في درجات الحرارة العالية (1250 ℃ ميجا باسكال) | ≥9.5 | |

| الانكسار ℃) | ≥1900 | |

| درجة حرارة تليين الحمل (0.2 ميجا باسكال T0.6 ℃) | ≥1680 | |

| معدل التغير في خط الاحتراق % (1500 ℃ × 2 ساعة) | ≤±1.2 | |

مميزات قرميد الكروم اكسيد الالمونيوم

يتميز طوب الكروم اكسيد الالمونيوم بصلابة عالية ومقاومة ممتازة للتآكل ومقاومة جيدة للصدمات الحرارية ومقاومة درجات الحرارة العالية. كما أنها تتمتع بثبات كيميائي قوي وتوصيل حراري منخفض، مما يضمن أداءً موثوقًا به في البيئات القاسية ذات درجات الحرارة العالية.

استخدام قرميد الكروم اكسيد الالمونيوم

- صناعة المعادن :الصناعة المعدنيةفرن صناعة الصلب، فرن التكرير، إلخ;

- صناعة الزجاج: فرن الزجاج;

- صناعة السيراميك: فرن بدرجة حرارة عالية، والذي يمكن أن يقاوم التآكل والتآكل في درجات الحرارة العالية ويزيد من عمر خدمة الفرن.