قرميد الكربون

- الكثافة السائبة g/سم3: ≥1.7

- قوة الانضغاط / ميجا باسكال: ≥36

- معدل الأكسدة / %: ≤8

- متوسط حجم المسام: ≤0.1

- المسامية المفتوحة / %: ≤15

- العينة: اختبار العينة متاح

وصف الطوب الكربوني

قرميد الكربون، وهو مادة حرارية، مصنوع من مواد أساسها الكربون مثل الأنثراسايت والجرافيت. ويتميز بمقاومة درجات الحرارة العالية والتمدد الحراري المنخفض ومقاومة ممتازة للتآكل، ويستخدم على نطاق واسع في صناعات الصلب والصناعات الكيميائية.

ورقة البيانات الفنية لقرميد الكربون كيروي الكربوني

| البارامترات الفيزيائية والكيميائية للطوب الكربوني | ||

|---|---|---|

| الفهرس | ||

| الكثافة السائبة جم/سم3 | ≥1.7 | |

| المسامية المفتوحة / % | ≤15 | |

| قوة الانضغاط / ميجا باسكال | ≥36 | |

| نفاذية الهواء Mpa | ≤1 | |

| معدل الأكسدة / % | ≤8 | |

| متوسط حجم المسام | ≤0.1 | |

| التوصيل الحراري، ≥ واط/ (م ك) | في درجة حرارة الغرفة | 16 |

| 600°C | 20 | |

مزايا الطوب الكربوني

مقاومة درجات الحرارة العالية

يمكن أن يتحمل الطوب الكربوني درجات الحرارة العالية للغاية دون أن يلين أو يتشوه، مما يحافظ على سلامته الهيكلية في البيئات الصناعية ذات الحرارة العالية

تمدد حراري منخفض

ويتميز بمعامل تمدد حراري منخفض، مما يمكّنه من مقاومة التشقق والتلف الناجم عن التغيرات السريعة في درجات الحرارة، مما يضمن ثباته على المدى الطويل.

مقاومة ممتازة للتآكل

يُظهر القرميد الكربوني مقاومة قوية لمختلف المواد المسببة للتآكل، سواءً كانت وسائط حمضية أو قلوية، مما يحمي المعدات في البيئات التي تتسم بكثافة المواد الكيميائية.

موصلية حرارية عالية

وبفضل الموصلية الحرارية الجيدة، يمكنها نقل الحرارة بكفاءة، وهو أمر مفيد لعمليات التبادل الحراري في الأفران والمفاعلات الصناعية.

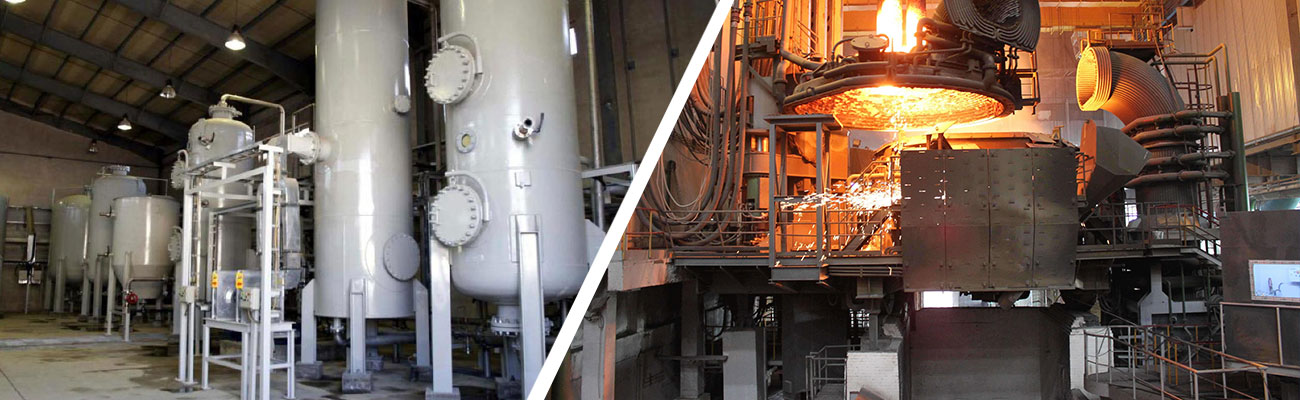

تطبيق الطوب الكربوني

يتميز قرميد الكربون، الذي يتميز بمقاومة ملحوظة لدرجات الحرارة العالية ومقاومة التآكل، باستخدامات متنوعة. ففي صناعة صناعة الحديد، تقوم بتبطين أفران الصهر لحماية جسم الفرن من الحديد المنصهر والخبث في درجات الحرارة العالية. في المصانع الكيميائية، يُستخدم قرميد الكربون في المفاعلات لمقاومة الوسائط المسببة للتآكل أثناء التفاعلات الكيميائية. كما أنها تُستخدم أيضًا في أفران صهر المعادن غير الحديدية، مما يضمن التشغيل المستقر في ظل الظروف القاسية وإطالة عمر المعدات.