- MgO 화학 성분 :≥95 %;

- 겉보기 다공성 :≤18 %;

- 벌크 밀도/(g/cm³): 2.31-2.4

- 굽힘 강도/(MPa): ≥58.80

- MgO% ≥:70/75/80 ZrO2 %≥:8/10/13;

- 겉보기 다공성%≤:19;

- 벌크 밀도(g/cm3)≥:2.95;

- 부하 시 내화도: ≥1600°C

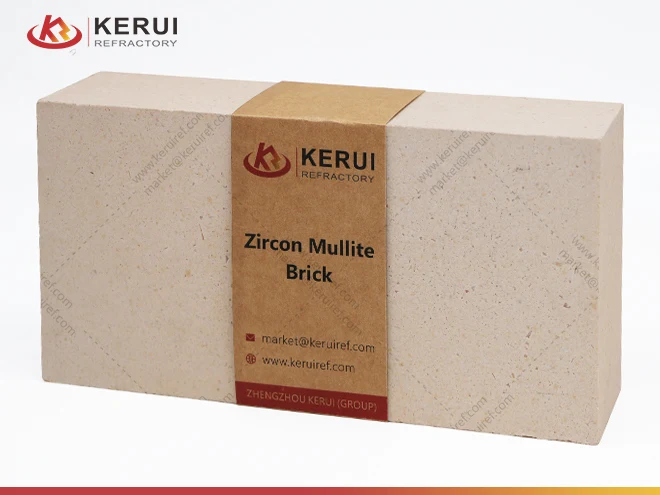

- Al2O3% (≥): 62-70

- Fe2O3)/%(≤): 1.5-1.8

- 하중 하에서의 내화도(℃)(≥): 1760-1780

- 샘플: 사용 가능;

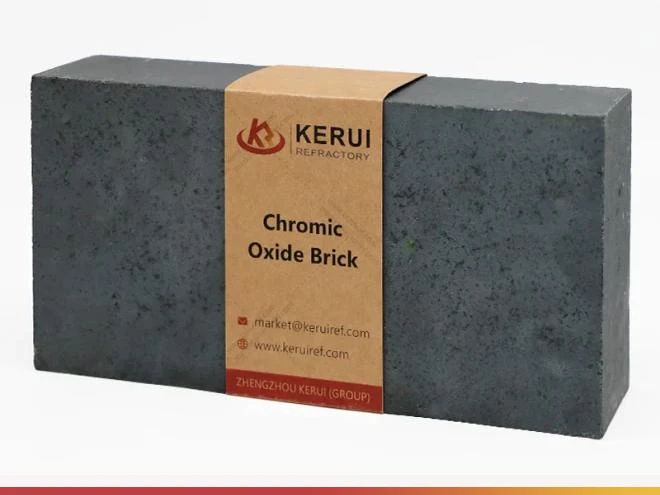

- 벌크 밀도 g/cm3:≥ 3.15;

- 냉간 분쇄 강도 (Mpa)≥90;

- 겉보기 다공성(%): ≤17;

- 크기: 230*114*65mm; 맞춤형 크기

- 벌크 밀도 g/cm3:≥ 3.15;

- 냉간 분쇄 강도 (Mpa)≥90;

- 겉보기 다공성(%): ≤17;

- 크기: 230*114*65mm; 맞춤형 크기

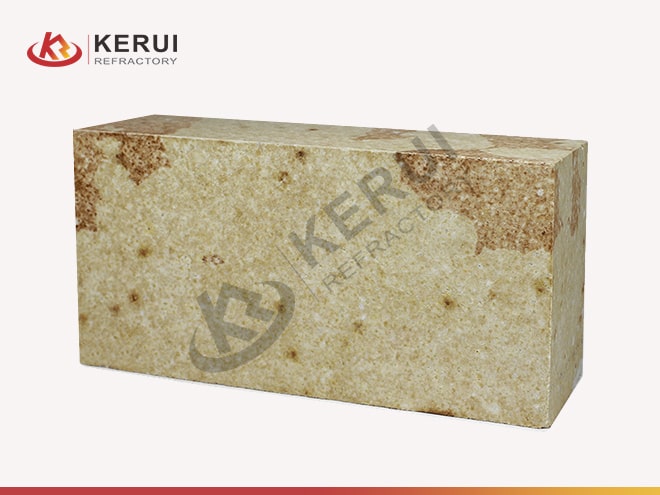

- Al2O3(%)≥: 42-72

- Fe2O3(%)≤: 0.5-1.0

- 벌크 밀도(g/cm³)≤: 0.6-1.1

- 냉간 분쇄 강도 (MPa)≥: 1.5-3.5

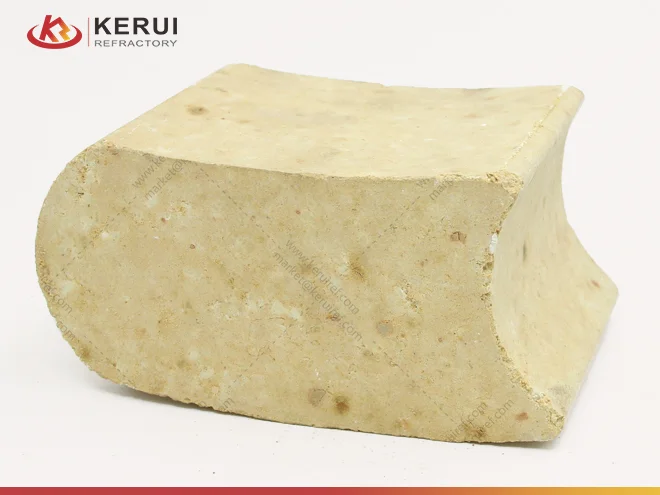

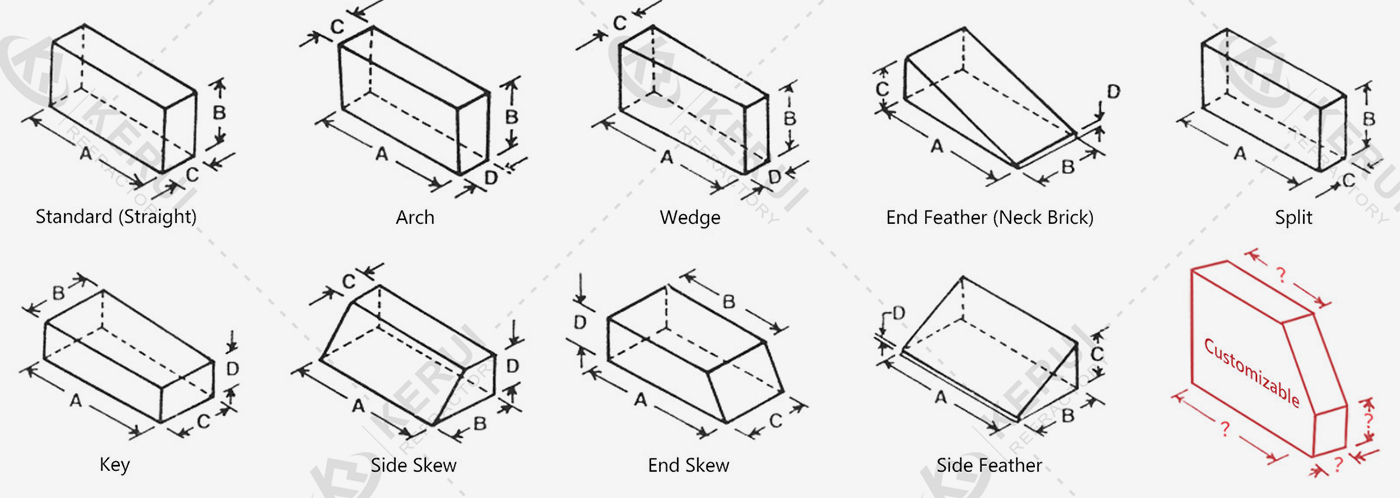

맞춤형 내화 벽돌

Kerui 내화물 공장은 고객의 요청에 따라 모든 종류의 모양의 벽돌을 사용자 정의 할 수 있습니다. 자체 공장과 자체 R&D 팀, 기술 팀, 생산 팀이 있기 때문입니다. 또한 각 시장에 익숙한 전문 영업 팀과 서비스 팀도 있습니다. 문의를 환영합니다!

케루이 내화 내화벽돌의 응용 분야

소결로 및 가마

소결로 및 가마내화 벽돌은 일반적으로 세라믹, 시멘트, 석회, 광석 및 기타 재료의 소결로 및 가마 건설에 사용됩니다. 내화 벽돌은 장시간 고온을 견딜 수 있습니다.

유리 용광로

유리 용광로유리 제조 산업에서 내화 벽돌은 유리 원료를 녹이기 위해 고온이 필요한 유리 용광로를 건설하는 데 사용됩니다.

철강 제련

철강 제련철강 산업에서 내화 벽돌은 고로, 컨버터, 전기 아크로 및 기타 제련 장비를 만드는 데 사용되어 고온과 화학적 공격을 견뎌냅니다.

석탄 가스화기 및 화학 산업

석탄 가스화기 및 화학 산업내화 벽돌은 석탄 가스화기, 화학 반응로 및 기타 화학 산업 분야에서도 사용되며, 고온과 부식성 화학 물질을 견뎌야 하기 때문입니다.

산업용 고온 용광로 본체

산업용 고온 용광로 본체내화 벽돌은 고온 제련로, 소각로, 유리로, 강철로 등과 같은 산업용 용광로 본체를 제조하는 데 자주 사용됩니다.

석탄 가스화기 및 화학 산업

석탄 가스화기 및 화학 산업내화 벽돌은 석탄 가스화기, 화학 반응로 및 기타 화학 산업 분야에서도 사용되며, 고온과 부식성 화학 물질을 견뎌야 하기 때문입니다.

내화 내화 벽돌의 생산 공정

저희는 전문 기술팀과 생산 장비를 갖춘 자체 공장을 보유하고 있습니다.

완전 자동 배치 시스템; 400-1000톤 성형 프레스 20세트; 2 * 168m 고온 터널 가마; 20000㎡ 보관 작업장.

제품 품질을 보장하고 생산 효율성을 개선하며 고객에게 가장 만족스러운 제품과 서비스를 제공하세요.

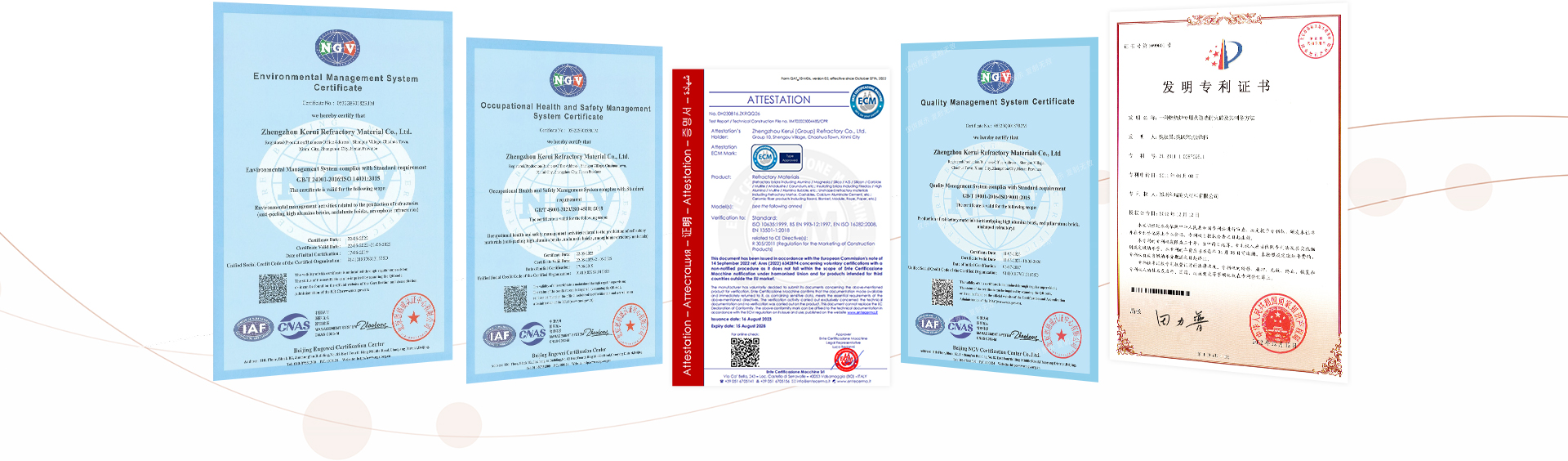

케루이 내화물 인증서

케루이 그룹은 ISO9001/ISO14001/OHSAS18001/CE/SGS 등 다수의 국제 인증을 보유하고 있습니다. 게다가,

케루이의 제품은 또한 많은 국내 인증서를 보유하고 있으며 품질이 매우 보장되며 국내외 고객들로부터 만장일치로 인정받고 있습니다.

케루이 내화물 제품 포장 및 배송

전체 제공 프로세스를 추적하고 Kerui의 전문가 팀이 최고의 전문성을 바탕으로 특정 프로젝트의 요구 사항을 해결합니다.

고객의 프로젝트에 필요한 경우 Kerui의 전문가 팀이 고객의 국가로 직접 방문하여 대면 기술 지원을 제공합니다.

케루이 내화물의 고객 사례

케루이 내화물은 중국 본토 외에도 아시아, 유럽, 아메리카, 아프리카, 오세아니아 등 전 세계 5대륙 50개 이상의 국가와 지역에 제품을 수출하고 있습니다.

전 세계 고객들로부터 인정과 높은 평가를 받고 있으며, 고객들의 재주문과 추천이 끊이지 않고 있습니다.

-

5대륙

-

50+국가

-

1700+성공 사례

-

4500+고객