Description of Dolomite Brick

Dolomite bricks, also known as magnesia-calcium bricks and MgO-CaO bricks, are refractory products made of 55-75% MgO and 18-42% CaO plus other binders and additives. Due to the combination of high-quality materials, dolomite high-temperature refractory bricks have high temperature resistance, thermal stability and alkalinity, making them very suitable for various harsh environments.

Technique Data of Kerui Dolomite Brick

| 아이템/등급 | MG-20 | MG-20A | MG-30 | MG-30A | MG-40 | MG-40A | MG-50 | |

|---|---|---|---|---|---|---|---|---|

| ω (CaO)/% | μ0 ≥ | 18 | 28 | 38 | 48 | |||

| ω (MgO+CaO)/% | μ0 ≥ | 92 | 94 | 92 | 94 | 92 | 94 | 94 |

| ω (SiO2+Al2O3+Fe2O3)/% | μ0 ≤ | 3 | 2.5 | 3 | 2.5 | 3 | 2.5 | 2.5 |

| 겉보기 다공성/% | μ0 ≤ | 15 | ||||||

| 냉간 분쇄 강도/MPa | μ0 ≥ | 60 | ||||||

| 0.2MPa Refractoriness Under Load T0.6/℃ | μ0 ≥ | 1650 | 1700 | 1650 | 1700 | 1650 | 1700 | 1700 |

Advantages of Dolomite Brick

Dolomite brick is characterized by high refractoriness and good thermal shock resistance. It has low porosity and excellent slag resistance. It can withstand high temperatures and complex chemical environments, ensuring stability and durability in industrial furnaces and other applications.

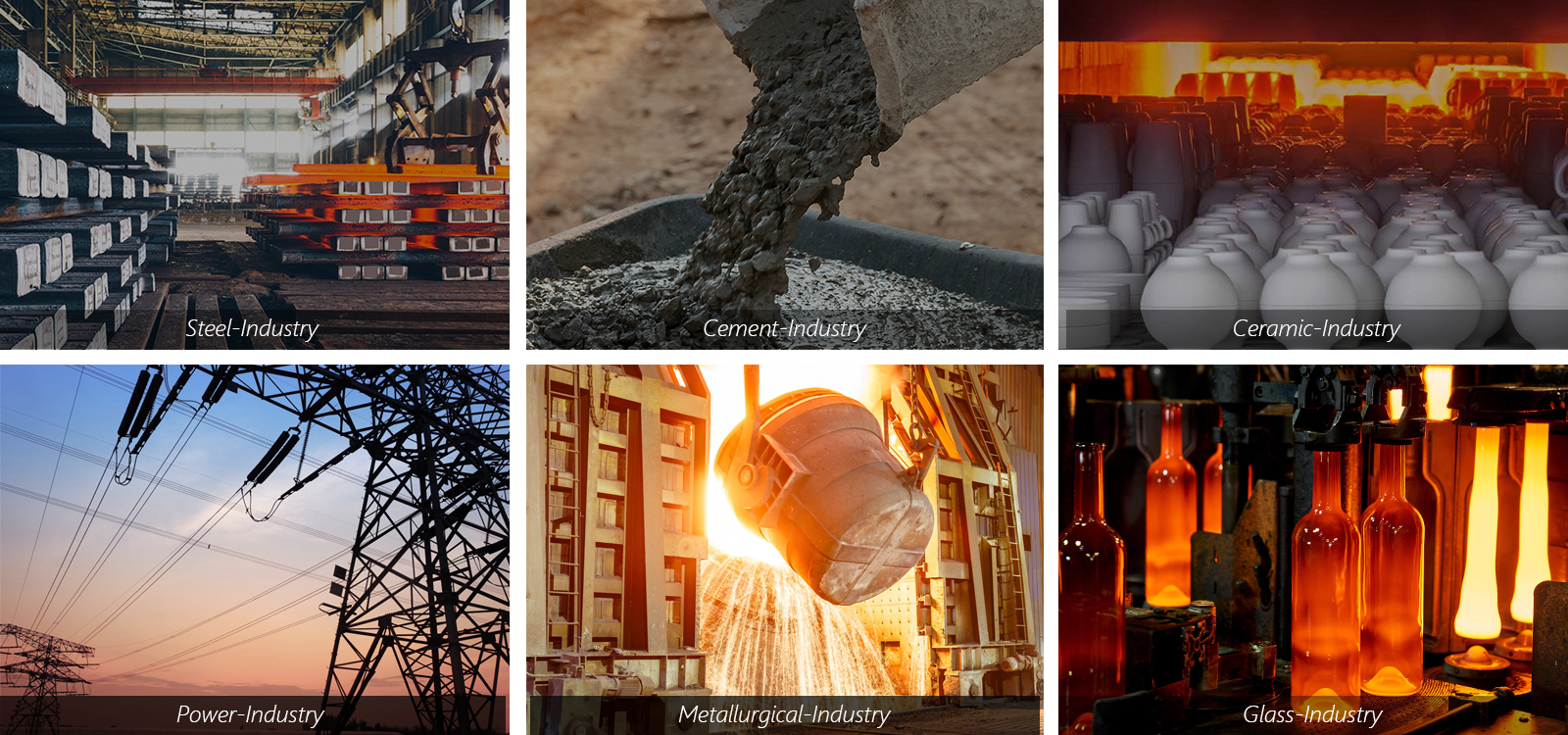

Application of Dolomite Brick

Dolomite bricks are widely used in various high-temperature industrial fields. They are commonly applied in steelmaking furnaces, such as electric arc furnaces and ladles, as well as in cement kilns and glass furnaces to resist high temperatures and protect the furnace linings.