카본 브릭에 대한 설명

내화 재료인 카본 브릭은 무연탄과 흑연과 같은 탄소 기반 물질로 만들어집니다. 내열성이 높고 열팽창이 적으며 내식성이 뛰어나 철강 및 화학 산업에서 널리 사용됩니다.

케루이 카본 브릭 기술 데이터 시트

| 탄소 벽돌의 물리적 및 화학적 매개변수 | ||

|---|---|---|

| 색인 | ||

| 벌크 밀도 g/cm3 | ≥1.7 | |

| 개방형 다공성 /% | ≤15 | |

| 압축 강도 / Mpa | ≥36 | |

| 공기 투과성 Mpa | ≤1 | |

| 산화 속도 /% | ≤8 | |

| 평균 모공 크기 | ≤0.1 | |

| 열 전도성, ≥W/(m k) | 실온에서 | 16 |

| 600°C | 20 | |

탄소 벽돌의 장점

고온 내성

탄소 벽돌은 연화나 변형 없이 초고온을 견딜 수 있어 고열 산업 환경에서도 구조적 무결성을 유지합니다.

낮은 열 팽창

열팽창 계수가 낮아 급격한 온도 변화로 인한 균열과 손상을 방지하여 장기적인 안정성을 보장합니다.

뛰어난 내식성

탄소 벽돌은 산성 또는 알칼리성 매질 등 다양한 부식성 물질에 대한 강한 내성을 보여 화학 물질이 많은 환경에서 장비를 보호합니다.

높은 열 전도성

열전도율이 우수하여 열을 효율적으로 전달할 수 있어 산업용 용광로와 원자로의 열 교환 공정에 유용합니다.

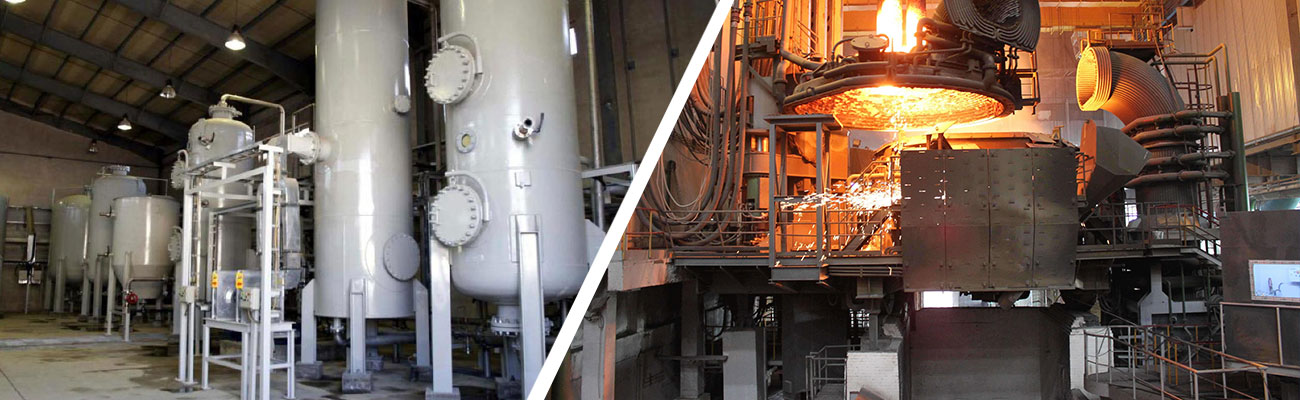

카본 브릭 적용

뛰어난 고온 저항성과 내식성을 자랑하는 탄소벽돌은 다양한 용도로 사용됩니다. 제철 산업에서는 용광로를 감싸고 고온의 용철과 슬래그로부터 용광로 본체를 보호합니다. 화학 공장에서 탄소 벽돌은 화학 반응 중 부식성 매체에 저항하기 위해 원자로에 사용됩니다. 또한 비철금속 제련로에서도 사용되어 열악한 조건에서 안정적인 작동을 보장하고 장비의 수명을 연장합니다.