- Ladrillo de alta alúmina

- Ladrillo refractario de sílice

- Ladrillo de corindón

- Ladrillo de arcilla refractaria

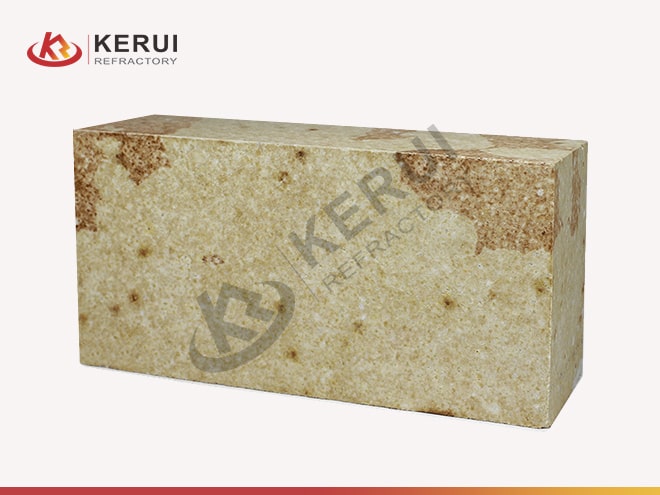

- Al2O3: 55-80%;

- Refractariedad bajo carga: 1420-1530℃;

- Resistencia al aplastamiento en frío: 40-70MPa;

- Tamaño estándar: 230*114*65mm;

- Color: Amarillo;

- Temperatura máxima de servicio: 1800℃;

- Al2O3: Máxima capacidad de servicio hasta 95%;

- Muestra: disponible;

- Porosidad aparente, %: ≤26;

- Resistencia al aplastamiento en frío, MPa: ≥40;

- Precio: Bajo Precio de fábrica;

- Muestra: disponible;

- MgO Composición química :≥95 %;

- Porosidad aparente :≤18 %;

- Densidad aparente/ (g/cm³): 2.31-2.4

- Resistencia a la flexión/ (MPa): ≥58,80

- MgO% (≥): 89-97.5

- Densidad aparente (g/cm³): 2.85-3.0

- Refractariedad bajo carga (℃): 1500-1700

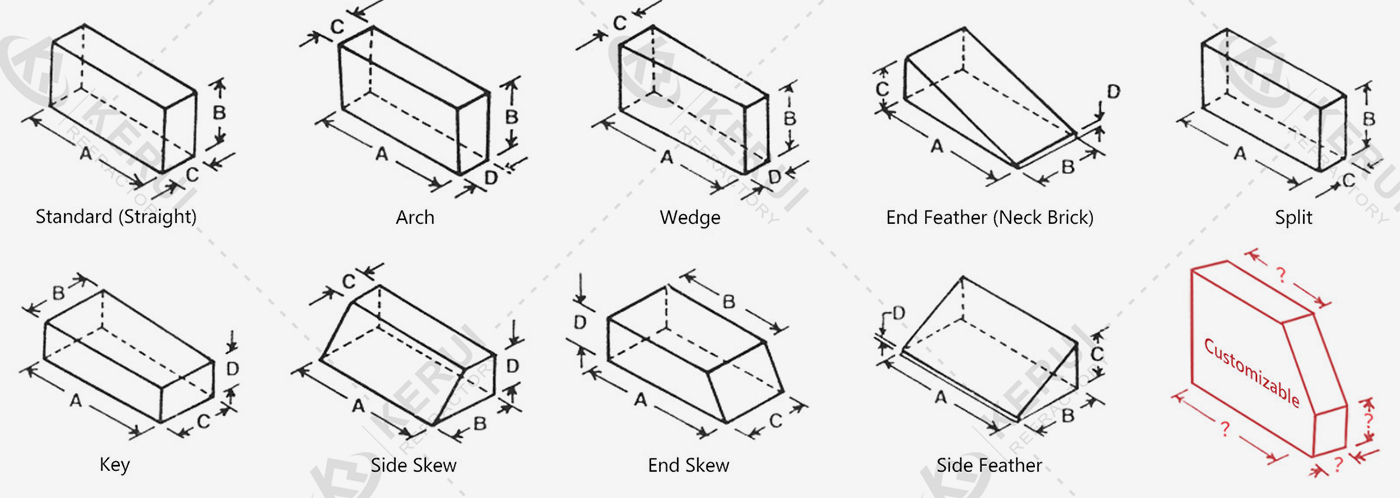

- Tamaño: 230*114*65mm; Tamaños personalizados

- MgO%: 69-85

- C%: 5-18

- Densidad aparente (g/cm³): 2.79-3.05

- Muestra: disponible;

- MgO%(≥): 45-65

- Cr2O3%(≥): 8-16

- Porosidad aparente/%(≤): 19-21

- Resistencia al aplastamiento en frío (MPa): 20-35

- MgO% ≥:70/75/80 ZrO2 %≥:8/10/13;

- Porosidad aparente%≤:19;

- Densidad aparente (g/cm3)≥:2,95;

- Refractariedad bajo carga:≥1600 °C

- Al2O3% (≥): 62-70

- Fe2O3)/%(≤): 1.5-1.8

- Refractariedad bajo carga (℃)(≥): 1760-1780

- Muestra: disponible;

- Temperatura máxima de servicio: 1700℃;

- Más de 85% Al2O3 y 0,45% Fe2O3;

- Color: Blanco;

- Más de 55MPa de resistencia al aplastamiento en frío;

- Densidad aparente g/cm3:≥ 3,15;

- Resistencia al aplastamiento en frío (Mpa)≥90;

- Porosidad aparente (%):≤17;

- Tamaño: 230*114*65mm; Tamaños personalizados

- Al2O3:≥30-70%;

- Refractariedad bajo carga: 1250-1480ºC;

- Bulk Density: 1.9-2.35g/cm³

- Muestra: disponible;

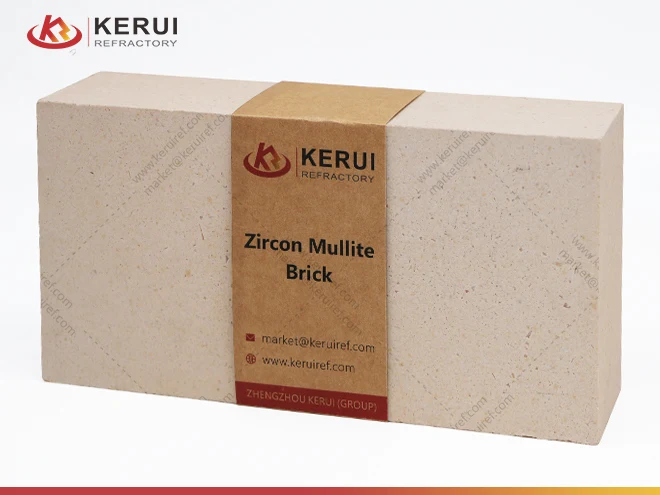

- ZrSiO4: ≥15-65%;

- Densidad aparente: 2,7-3,7 g/cm³;

- Refractariedad bajo carga: 1550-1650ºC;

- Resistencia al aplastamiento en frío: ≥100MPa;

- ZrO2%: ≥ 16

- Fe2O3%: ≤ 0,5

- Densidad aparente (g/cm³): ≥ 2,70

- Resistencia al aplastamiento en frío/MPa: ≥ 70

- Porosidad aparente %: ≤20

- Refractariedad bajo carga°C: ≥1650℃

- Al2O3: ≥45%

- Densidad aparente g/cm3: ≥3,2

- Densidad aparente g/cm3:≥ 3,15;

- Resistencia al aplastamiento en frío (Mpa)≥90;

- Porosidad aparente (%):≤17;

- Tamaño: 230*114*65mm; Tamaños personalizados

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Densidad aparente (g/cm³)(≥): 2.90

- Resistencia al aplastamiento en frío(≥): 50MPa

- MgO/%(≥): 80

- Al2O3/%(≥): 10

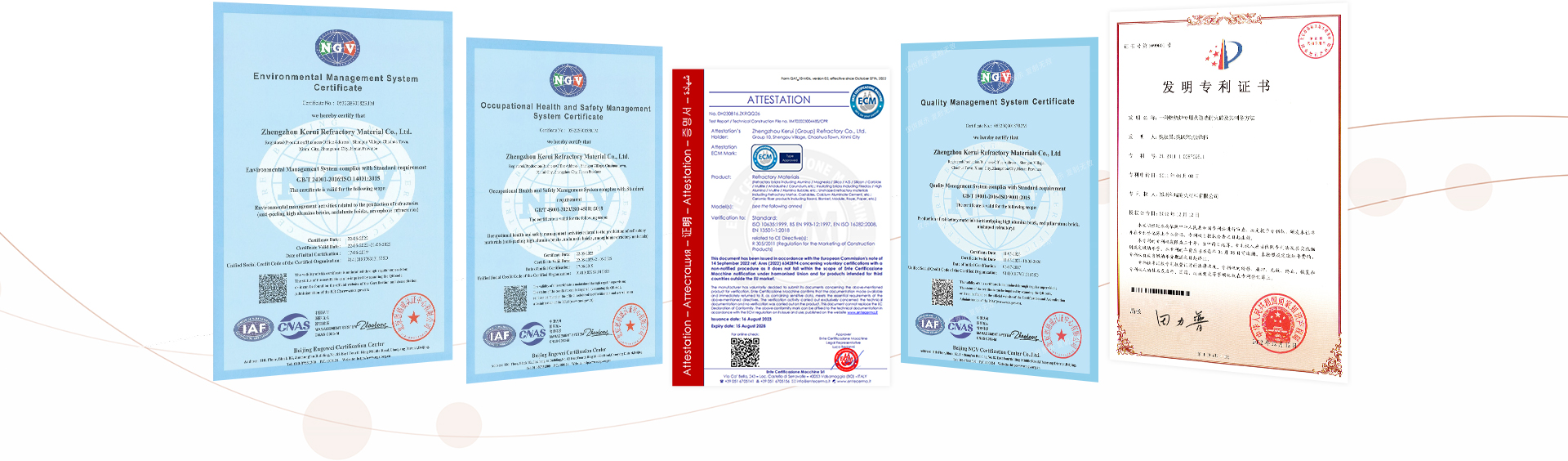

- Certificación: ISO9001/ISO14001 /ISO45001/ISO50001

- MgO/%(≥): 80

- Al2O3/%(≥): 10

- Densidad aparente (g/cm³)(≥): 2.90

- Muestra: posibilidad de probar la muestra

- Al2O3/%: 95-98

- SiO2/%: 0,15-0,5

- Fe2O3/%: 0,1-0,3

- Refractariedad bajo carga: 1700MPa

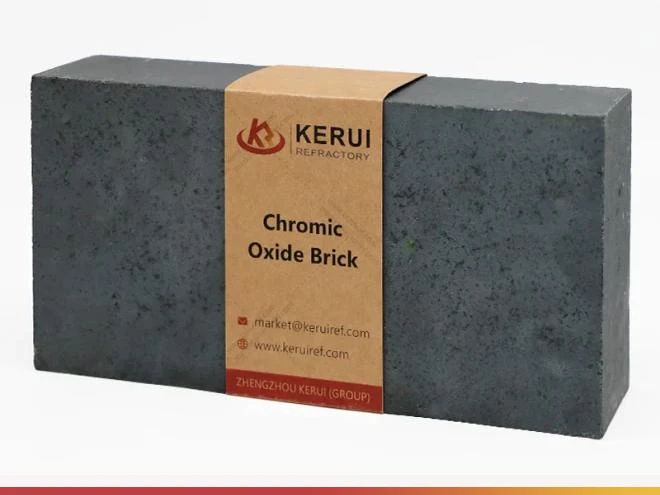

- Cr2O3 %≥:50-93;

- Porosidad aparente %:≤16;

- Densidad aparente g/cm3≥:3,5-4,25;

- Temperatura de reblandecimiento de la carga, 0,2MPa 0,6%:≥1700;

- Densidad aparente g/cm3: ≥3,25;

- Porosidad aparente %: ≤15;

- Resistencia a la presión(Mpa)≥1800;

- Temperatura de reblandecimiento de la carga(0,2Mpa T0,6 ℃): ≥168;

- Densidad aparente g/cm3: ≥1,7

- Resistencia a la compresión / Mpa: ≥36

- Tasa de oxidación /%: ≤8

- Tamaño medio de los poros: ≤0,1

- SiO2%: ≥94

- Fe2O3/%: ≤1,4

- Densidad real (g/cm³): ≤2,35

- Refractariedad bajo carga (℃): ≥1650

- Al2O3 ≥/%: 60-65

- Densidad aparente: 2,55-2,65 g/cm³.

- Muestra: posibilidad de probar la muestra

- Resistencia al aplastamiento en frío: 85-90MPa

- Al2O3: ≥60-65%;

- SiO2: ≥32-37%;

- Densidad aparente: 2,40-2,55 g/cm³;

- Resistencia al aplastamiento en frío: 45-60MPa;

- Ladrillo de magnesia

- Ladrillo de Magnesia Espinela

- Ladrillo de carbón de magnesia

- Ladrillo cromado Magnesia

- Refractariedad: ≥1730-1810℃;

- Al2O3: ≥55-80%;

- Densidad aparente: 2,15-2,8 g/cm³;

- Muestra: disponible;

- Used for ladles and tundishes;

- Used for rotary kilns;

- Resist heat and chemical corrosion;

- Used for continuous casting process;

- Hoyos: 7/19/31/37/65/otros;

- Entrega: 15-30 días laborables;

- Precio: Bajo Precio de fábrica;

- Muestra: disponible;

- Al2O3 %: >36

- Porosidad aparente %: 17-26;

- Densidad aparente g/cm3: >2.1;

- Refractariedad ℃: >1700;

- Al2O3(%)≥: 42-72

- Fe2O3(%)≤: 0.5-1.0

- Densidad aparente (g/cm³)≤: 0.6-1.1

- Resistencia al aplastamiento en frío (MPa)≥: 1.5-3.5

- MgO+CaO% (≥):92-94;

- CaO% (≥):18-48;

- Porosidad aparente(%):15,0;

- Resistencia al aplastamiento en frío (MPa):60;

- Resistencia a los ácidos ≥/%: 99,8

- Absorción de agua ≤/%: 2

- Densidad aparente/ (g/cm³): 2.31-2.4

- Resistencia a la flexión/ (MPa): ≥58,80

- Al2O3(%)≥: 40-77

- Fe2O3(%)≤: 0.5-1.0

- Densidad aparente (g/cm³)≤: 0.55-1.35

- Resistencia al aplastamiento en frío (MPa)≥: 0.9-3.5

Ladrillos refractarios a medida

La fábrica de Kerui Refractory puede personalizar todo tipo de ladrillos conformados según la petición del cliente. Porque tenemos fábrica propia, y nuestro propio equipo de I+D, equipo técnico, equipo de producción. Además, también tenemos un equipo profesional de ventas y equipo de servicio que están familiarizados con cada mercado. ¡Así que bienvenido a la investigación!

Aplicaciones de los ladrillos refractarios Kerui

Hornos de sinterización

Hornos de sinterizaciónLos ladrillos refractarios se utilizan habitualmente en la construcción de hornos de sinterización y hornos para cerámica, cemento, cal, minerales y otros materiales. Son capaces de soportar altas temperaturas durante largos periodos de tiempo.

Hornos de vidrio

Hornos de vidrioEn la industria de fabricación de vidrio, los ladrillos refractarios se utilizan para construir hornos de vidrio que requieren altas temperaturas para fundir la materia prima del vidrio.

Fundición de acero

Fundición de aceroEn la industria siderúrgica, los ladrillos refractarios se utilizan en la construcción de altos hornos, convertidores, hornos de arco eléctrico y otros equipos de fundición para resistir altas temperaturas y ataques químicos.

Gasificadores de carbón e industria química

Gasificadores de carbón e industria químicaLos ladrillos refractarios también se utilizan en gasificadores de carbón, reactores químicos y otras aplicaciones de la industria química, ya que estos hornos deben soportar altas temperaturas y productos químicos corrosivos.

Cuerpo de horno industrial de alta temperatura

Cuerpo de horno industrial de alta temperaturaLos ladrillos refractarios se utilizan a menudo para fabricar cuerpos de hornos industriales, como hornos de fundición de alta temperatura, incineradores, hornos de vidrio, hornos de acero, etc.

Gasificadores de carbón e industria química

Gasificadores de carbón e industria químicaLos ladrillos refractarios también se utilizan en gasificadores de carbón, reactores químicos y otras aplicaciones de la industria química, ya que estos hornos deben soportar altas temperaturas y productos químicos corrosivos.

Proceso de producción de ladrillos refractarios para incendios

Tenemos nuestra propia fábrica con un equipo técnico profesional y equipos de producción.

Con sistema de dosificación totalmente automático; 20 juegos de prensas de conformado de 400-1000 toneladas; hornos túnel de alta temperatura de 2 * 168 m; taller de almacenamiento de 20000㎡.

Garantizar la calidad de los productos, mejorar la eficacia de la producción y ofrecer a los clientes los productos y servicios más satisfactorios.

Certificados de Kerui Refractory

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides,

Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

Embalaje y envío de productos refractarios Kerui

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism.

If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

Caso de cliente de Kerui Refractory

Además de China continental, Kerui Refractory ha exportado productos a más de 50 países y regiones de los 5 continentes del mundo, incluidos Asia, Europa, América, África y Oceanía.

Hemos recibido el reconocimiento y los elogios de clientes de todo el mundo, y recibimos constantemente pedidos repetidos y recomendaciones de clientes.

-

5Continentes

-

50+Países

-

1700+Casos de éxito

-

4500+Clientes