Ladrillo refractario de alta alúmina

Se utiliza para revestir hornos eléctricos siderúrgicos, hornos de fusión de vidrio y hornos rotatorios de cemento.

- Al2O3: 48-80%;

- Refractariedad bajo carga: 1420-1530℃;

- Resistencia al aplastamiento en frío: 40-70MPa;

- Tamaño estándar: 230*114*65mm;

- Certificación: ISO9001/ISO14001/ISO45001/ISO50001;

- Muestra: disponible;

Descripción del ladrillo refractario de alta alúmina

El ladrillo de alta alúmina es un tipo de producto refractario de silicato de aluminio con un contenido de óxido de aluminio (Al2O3) superior a 48%. Se forma y calcina a partir de bauxita u otras materias primas con alto contenido en alúmina. Alta estabilidad térmica, refractariedad por encima de 1770°C. Tiene buena resistencia a la escoria y se utiliza para el revestimiento de hornos eléctricos de fabricación de acero, hornos de fusión de vidrio y hornos rotatorios de cemento.

Datos técnicos de los ladrillos refractarios de alta alúmina Kerui

| Artículo/Grado | LZ-80 | LZ-75 | LZ-70 | LZ-65 | LZ-55 | LZ-48 | LZ-75G | LZ-65G | LZ-55G | |

|---|---|---|---|---|---|---|---|---|---|---|

| ω (Al2O3)/% | μ0 ≥ | 80 | 75 | 70 | 65 | 55 | 48 | 75 | 65 | 55 |

| σ | 1.5 | |||||||||

| Porosidad aparente/% | μ0 ≤ | 21 (23) | 24 (26) | 24 (26) | 24 (26) | 22 (24) | 22 (24) | 19 | 19 | 19 |

| σ | 1.5 | |||||||||

| Resistencia al aplastamiento en frío/MPa | μ0 ≥ | 70 (60) | 60 (50) | 55 (45) | 50 (40) | 45 (40) | 40 (35) | 65 | 60 | 50 |

| Xmin | 60 (50) | 50 (40) | 45 (35) | 40 (30) | 35 (30) | 30 (35) | 55 | 50 | 40 | |

| σ | 15 | |||||||||

| 0.2MPa Refractariedad Subcarga/℃ | μ0 ≥ | 1530 | 1520 | 1510 | 1500 | 1450 | 1420 | 1520 | 1500 | 1470 |

| σ | 13 | |||||||||

| Cambio lineal permanente/% | Xmin Xmax |

1500℃*2h -0.4~0.2 |

1450℃*2h -0.4~0.1 |

1500℃*2h -0.2~0.1 |

1450℃*2h -0.2~0 |

|||||

Ventajas de los ladrillos refractarios de alta alúmina

Alta refractariedad

La refractariedad de los ladrillos de alta alúmina es superior a la de los ladrillos de arcilla y los ladrillos de semisílice, alcanzando 1750~1790°C, lo que constituye un material refractario de alto grado.

Temperatura de reblandecimiento de la carga

Dado que el Al2O3 de los productos de alto contenido en alúmina es elevado, la cantidad de impurezas es menor y la formación de vidrio fusible es menor, la temperatura de reblandecimiento bajo carga es superior a la de los ladrillos de arcilla.

Excelente resistencia al choque térmico

Los ladrillos de alta alúmina tienen una excelente resistencia al choque térmico, por lo que pueden soportar cambios rápidos de temperatura sin agrietarse.

Excelente resistencia a la escoria

El contenido de Al2O3 en los ladrillos de alta alúmina es alto, lo que se aproxima a los materiales refractarios neutros, y puede resistir la erosión de la escoria ácida y la escoria alcalina. Debido a que contiene SiO2, la capacidad de resistencia a la escoria alcalina es más débil que la de la escoria ácida.

Buena resistencia mecánica

Una buena resistencia mecánica ayuda a resistir tensiones mecánicas como la dilatación y la contracción térmicas.

Baja conductividad térmica

Su baja conductividad térmica significa que proporcionan un excelente aislamiento y ayudan a reducir la pérdida de calor.

Aplicación de los ladrillos refractarios de alta alúmina

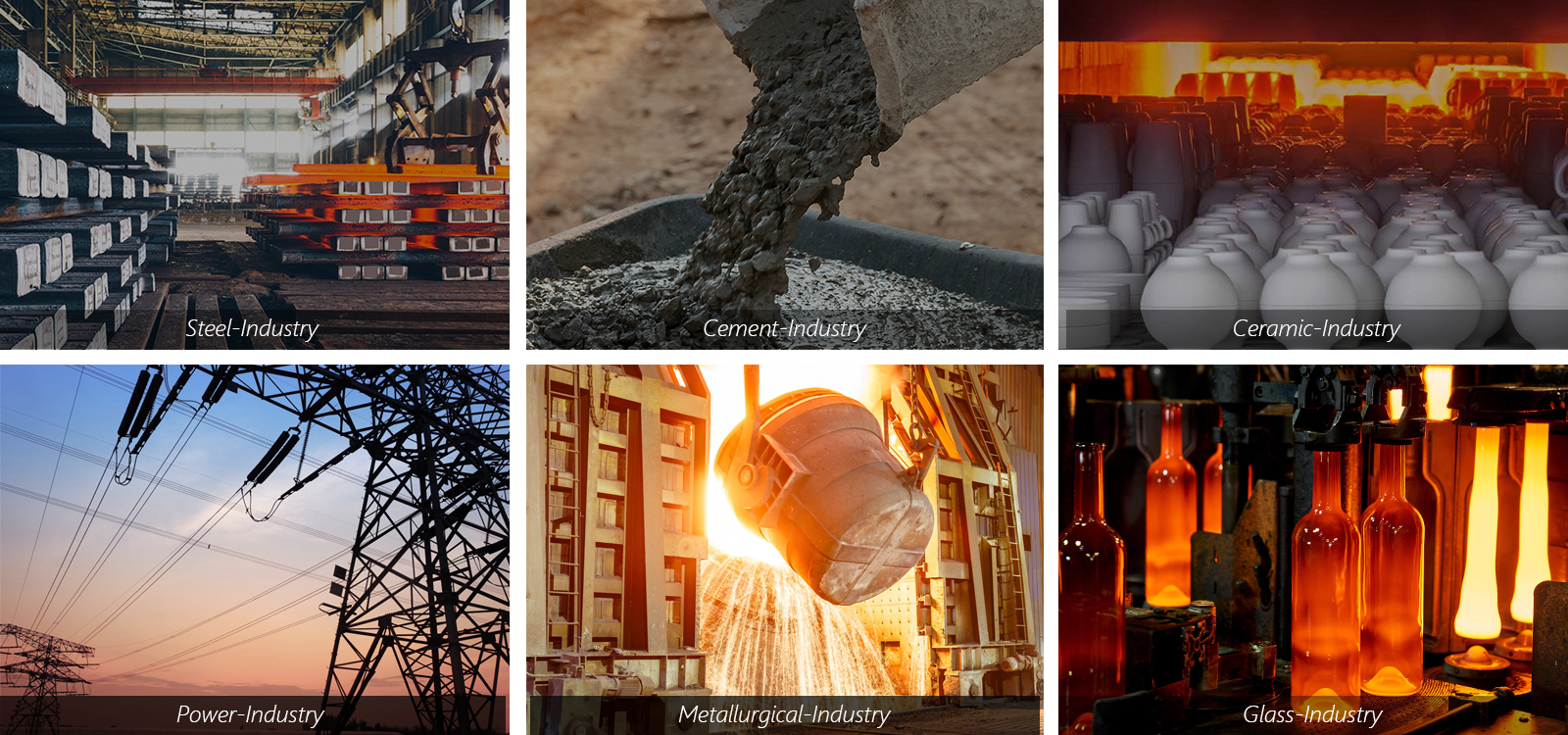

- Industria siderúrgica: alto horno, horno alto caliente, horno eléctrico, cuchara de colada, artesa de colada, horno de calentamiento, horno de refinado, horno de calentamiento, horno de recocido, cúpula;

- Industria de metales no férreos: horno de fundición, horno de refinado, horno de reverbero, convertidor;

- Industria de materiales de construcción: horno de cemento, horno de vidrio, horno de cerámica, horno de cal, vagoneta de horno, horno túnel;

- Energía e incineración: horno de coque, caldera de lecho fluidizado circulante, tostador de carbón, incinerador.