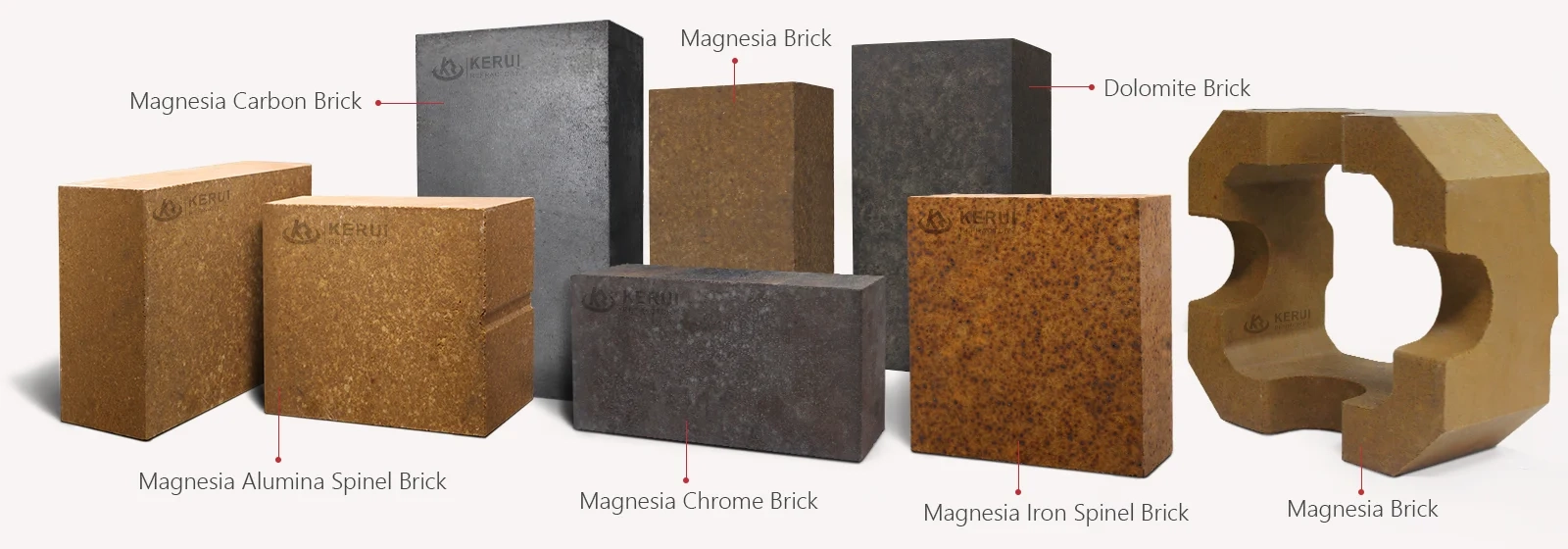

Magnesia-Ziegel

Mainly used in alkaline open-hearth furnaces, electric furnace bottoms and furnace walls for steelmaking.

- MgO% (≥): 89-97.5

- Schüttdichte (g/cm³): 2.85-3.0

- Refraktärität unter Last (℃): 1500-1700

- Kaltstauchfestigkeit (MPa): 45-60

- Zertifizierung: ISO9001/ISO14001/ISO45001/ISO50001

- Probe: Prüfung der Probe ist verfügbar

Description of Magnesia Brick

The main component of magnesia bricks is magnesium oxide, and the main crystal is periclase. It is widely used in steel-making furnace linings, ferroalloy furnaces, iron mixing furnaces, non-ferrous metallurgical industrial furnaces, lime kilns for building materials, glass industry re-generator grids and Heat exchangers, high-temperature calcining kilns and tunnel kilns in the refractory industry, etc.

Kerui Magnesia Brick Technical Data Sheet

| Artikel/Güteklasse | M-98 | M-97A | M-97B | M-95A | M-95B | M-91 | M-89 | |

|---|---|---|---|---|---|---|---|---|

| ω (MgO)/% | μ0 ≥ | 97.5 | 97.0 | 96.5 | 95.0 | 94.5 | 91.0 | 89.0 |

| σ | 1.0 | 1.5 | ||||||

| ω (SiO2)/% | μ0 ≤ | 1.00 | 1.20 | 1.50 | 2.00 | 2.50 | / | / |

| σ | 0.30 | |||||||

| ω (CaO)/% | μ0 ≤ | / | / | / | 2.00 | 2.00 | 3.00 | 3.00 |

| σ | 0.30 | |||||||

| Scheinbare Porosität/% | μ0 ≤ | 16 | 16 | 18 | 16 | 18 | 18 | 20 |

| σ | 1.5 | |||||||

| Schüttdichte (g/cm³) | μ0 ≥ | 3.00 | 3.00 | 2.95 | 2.90 | 2.85 | ||

| σ | 0.30 | |||||||

| Kaltstauchfestigkeit/MPa | μ0 ≥ | 60 | 60 | 60 | 60 | 50 | ||

| Xmin | 50 | 50 | 50 | 50 | 45 | |||

| σ | 10 | |||||||

| 0,2MPa Feuerfestigkeit Unterlast/℃ | μ0 ≥ | 1700 | 1700 | 1650 | 1560 | 1500 | ||

| σ | 15 | |||||||

| Permanente lineare Veränderung/% | Xmin~Xmax | 1650℃*2h -0.2-0 |

1650℃*2h -0.3-0 |

1600℃*2h -0.5-0 |

1600℃*2h -0.6-0 |

|||

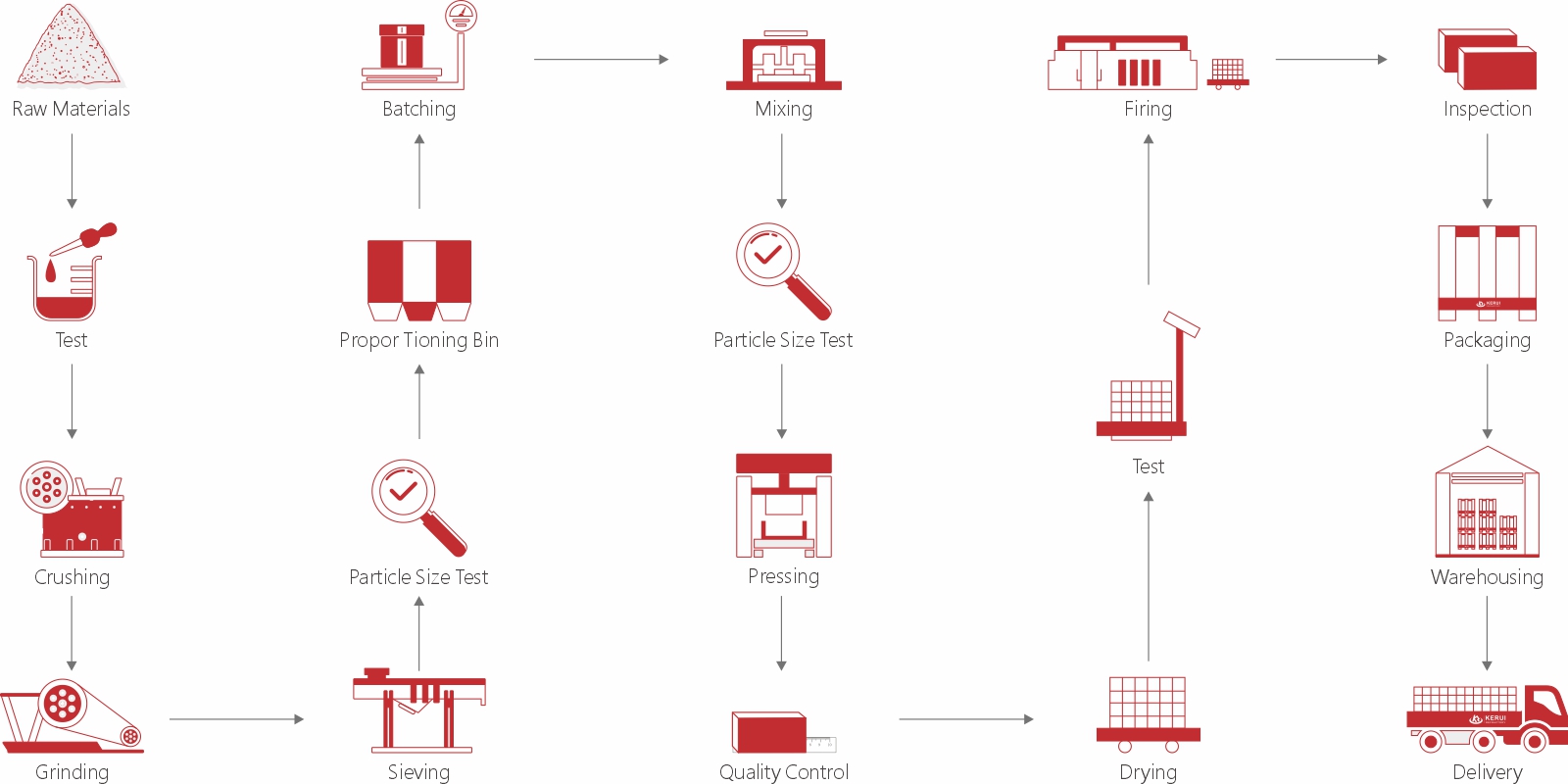

Manufacturing Process of Magnesia Brick

Wir verfügen über eine eigene Fabrik mit einem professionellen technischen Team und Produktionsanlagen. Mit vollautomatischem Dosiersystem; 20 Sätze von 400-1000-Tonnen-Formpressen; 2 * 168m Hochtemperatur-Tunnelöfen; 20000㎡ Lagerhalle. Sicherstellung der Produktqualität, Verbesserung der Produktionseffizienz und Versorgung der Kunden mit den zufriedenstellendsten Produkten und Dienstleistungen.

Advantages of Magnesia Brick

Refractory Performance

Refractory magnesia bricks can withstand extremely high temperatures, often reaching over 1500 degrees Celsius. Magnesia brick is an excellent refractory material that can withstand high temperature environments without losing its structural strength.

Excellent Slag Resistance

Magnesia bricks are alkaline refractory bricks that have strong resistance to alkaline slags, and are often used as masonry materials for alkaline kilns. Magnesia bricks have high strength and hardness and can withstand greater pressure and load.

Gute Wärmeleitfähigkeit

Refractory magnesia bricks have high thermal conductivity and can absorb and release heat quickly. This makes it very effective in applications where rapid heat transfer is required, such as high-temperature furnaces, kilns, etc.

Long Life and Durability

Magnesia refractory bricks have a long service life due to their resistance to high temperature and chemical attack. It is not easily damaged and degraded, and can stably assume the function of a fire-resistant structure for a long time

Thermal Expansion Adaptability

The linear expansion coefficient of magnesia bricks increases with temperature. In high-temperature environments, it can quickly conduct and dissipate heat, prevent the accumulation of thermal stress, and reduce the risk of structural damage.

Leichtes Material

Compared with other refractory materials, magnesia bricks have lower density and lighter weight. This makes it useful in some situations where structural load needs to be reduced, and also facilitates the construction and transportation process.

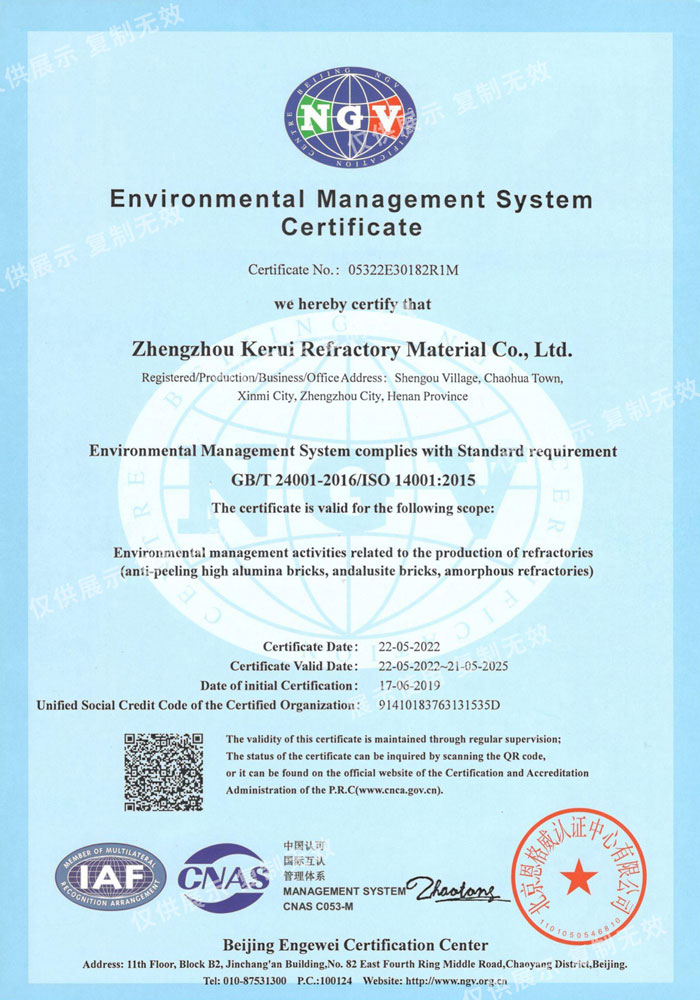

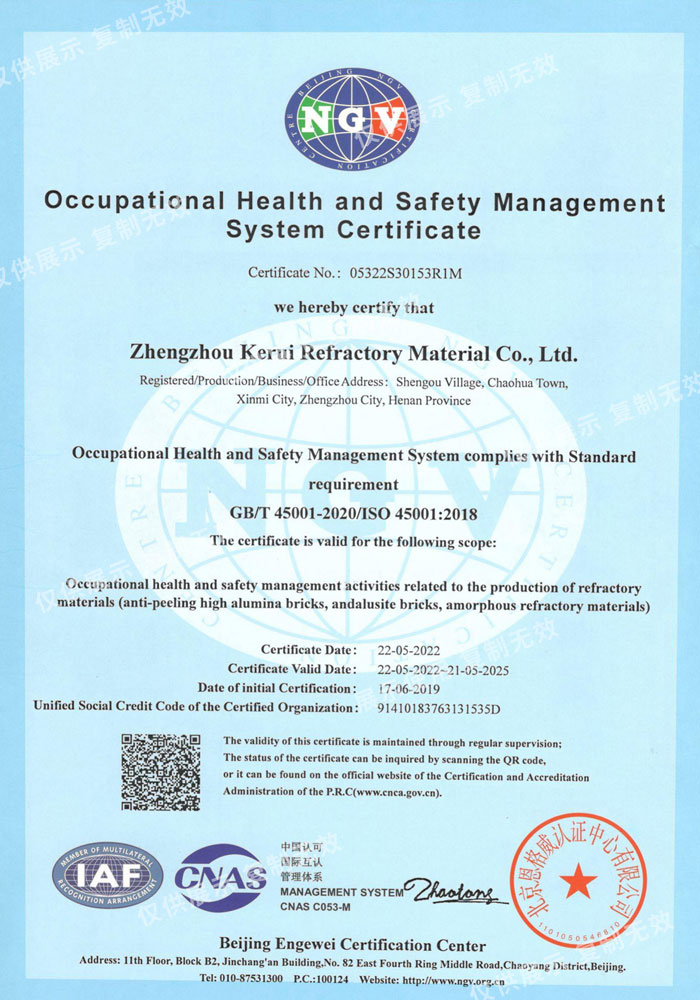

Bescheinigungen von Kerui Refractory

Die Kerui Gruppe verfügt über eine Reihe von internationalen Zertifizierungen, wie z. B., ISO9001/ISO14001/OHSAS18001/CE/SGS. Außerdem haben die Produkte von Kerui viele inländische Zertifikate, die Qualität ist sehr garantiert, und sie wurden einstimmig von Kunden im In- und Ausland anerkannt.

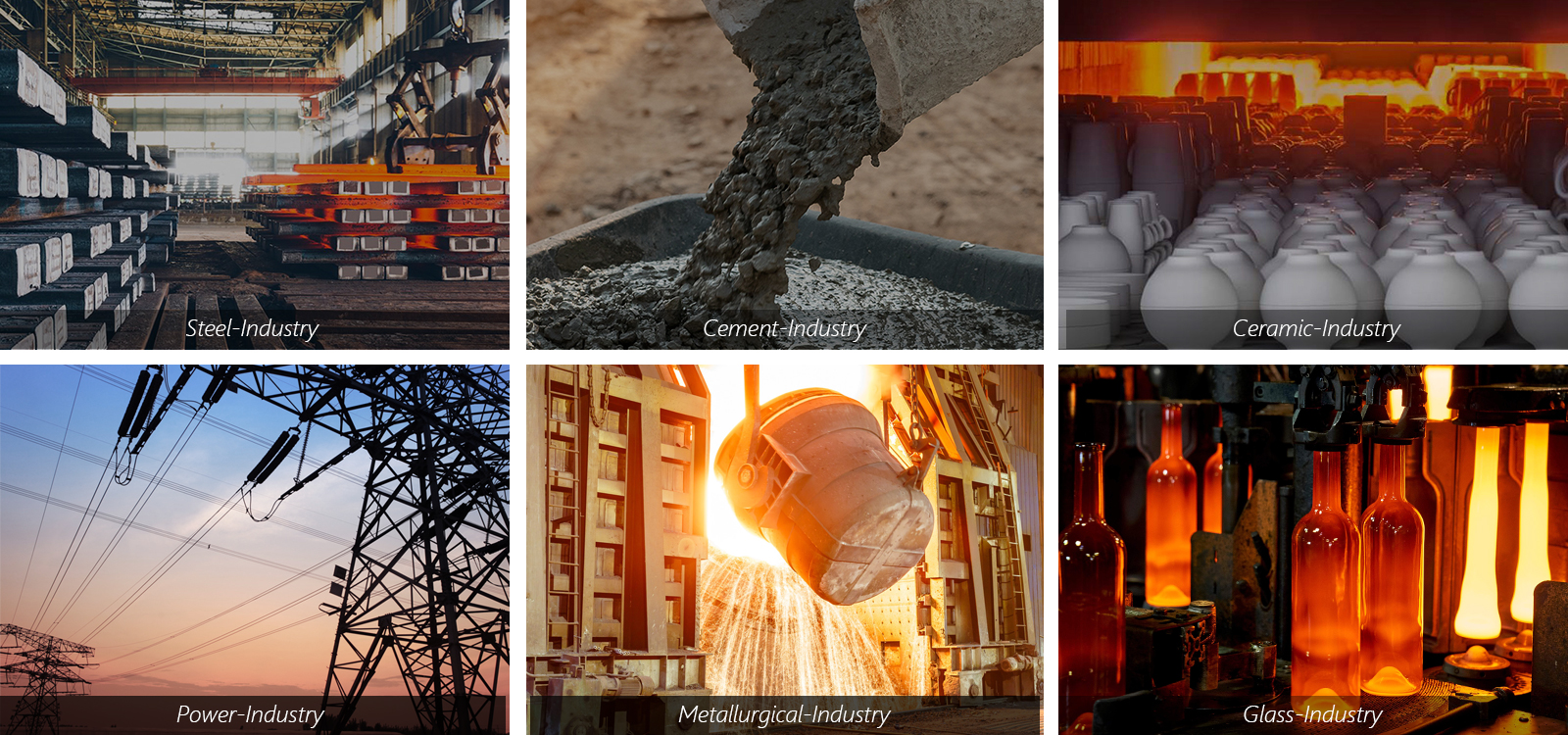

Application of Magnesia Brick

Metallurgische Industrie

Refractory magnesia bricks are widely used in high-temperature equipment in the metallurgical industry, such as steel furnaces, non-ferrous metal smelting furnaces, converters, electric furnaces and railway blast furnaces. They can withstand high temperatures and chemical attack, protect the furnace structure and keep the temperature inside the furnace stable.

Glasindustrie

In the glass manufacturing process, refractory magnesia bricks are often used in equipment such as glass kilns, fiberglass ladles and glass tanks. They are able to withstand the high temperatures of glass melting and have good resistance to thermal shock and chemical stability. Ensure the stability and efficiency of the glass production process.

Chemical industry

Refractory magnesia bricks are widely used in chemical plants and refineries. They resist corrosion from chemicals and are used in equipment such as reactors, furnaces, tanks and pipes. Refractory magnesia bricks are ideal for handling corrosive media and high-temperature reactions in the chemical industry.

Elektrizitätswirtschaft

In the electric power industry, refractory magnesia bricks are often used in high-temperature equipment such as boilers, combustion chambers and chimneys in power stations. They are able to withstand high temperatures and thermal stresses, protect equipment structures and improve combustion efficiency.

High-temperature Furnace

Refractory magnesia bricks are widely used in various high-temperature furnaces, including steel furnaces, aluminum furnaces, copper furnaces, glass furnaces, cement kilns, etc. They are able to withstand high temperatures and thermal shocks and maintain the structural stability of the furnace. Ideal for various high temperature furnaces.

Other Industries

Refractory magnesia bricks can also be used in some other fields, such as the construction industry, ceramics industry, ceramic kilns, etc. In these applications, refractory magnesia bricks can be used in furnaces, chimneys, furnace linings, insulation panels and other structures to provide fire resistance and heat insulation functions.

Labor von Kerui Refractory

Kerui verfügt über ein professionelles Qualitätsprüfungslabor. Hochtemperatur-Wiedererwärmungs-/Kriechprüfungsofen; Prüfstand für die Druck-/Biegefestigkeit von feuerfesten Materialien; Plattform zur Prüfung der Zusammensetzung und Inspektion von feuerfesten Materialien; Labor für physikalische/chemische Eigenschaften von feuerfesten Materialien.

KERUI FEUERFESTE PRODUKTE VERPACKUNG&VERSAND

Der gesamte Lieferprozess wird nachverfolgt, und das Expertenteam von Kerui löst die spezifischen Projektanforderungen mit höchster Professionalität. Wenn das Projekt des Kunden es erfordert, reist das Kerui-Expertenteam in das Land des Kunden, um dort persönlich technische Unterstützung zu leisten.

KUNDENFALL KERUI FEUERFEST

Neben dem chinesischen Festland hat Kerui Refractory seine Produkte in mehr als 50 Länder und Regionen auf 5 Kontinenten exportiert, darunter Asien, Europa, Amerika, Afrika und Ozeanien. Wir haben von Kunden aus der ganzen Welt Anerkennung und hohes Lob erhalten und werden von ihnen immer wieder beauftragt und weiterempfohlen.