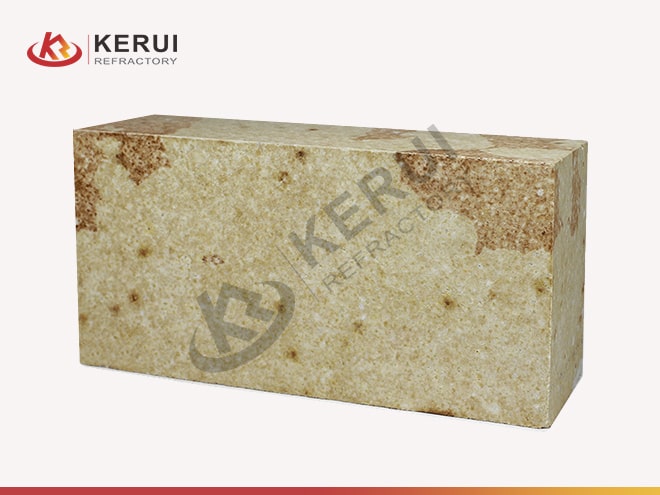

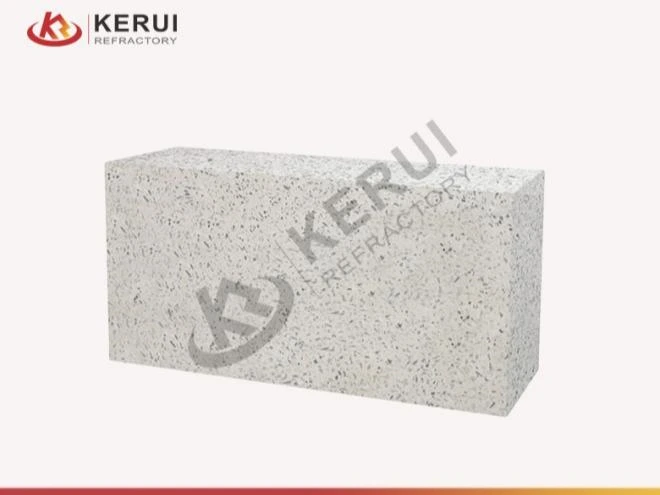

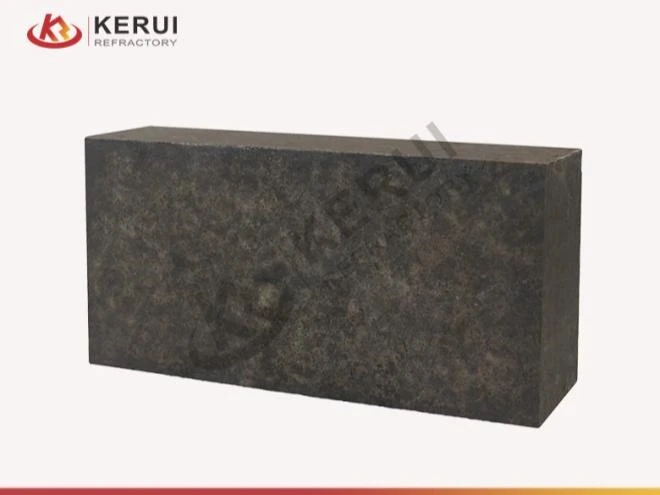

- Refractoriness: ≥1730-1810℃;

- Al2O3: ≥55-80%;

- Bulk Density: 2.15-2.8g/cm³;

- 样品:可提供;

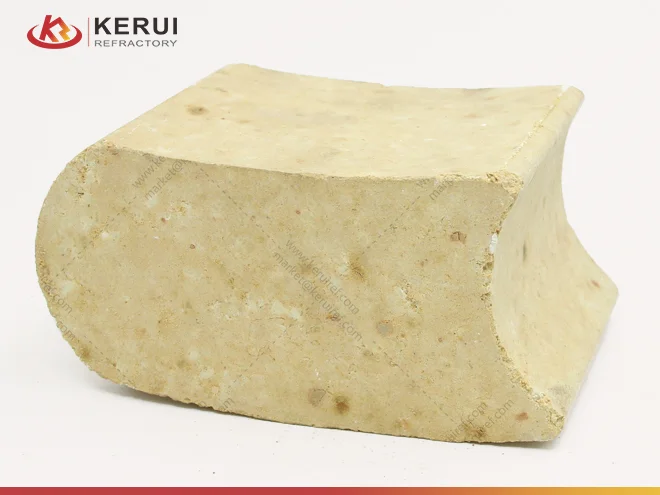

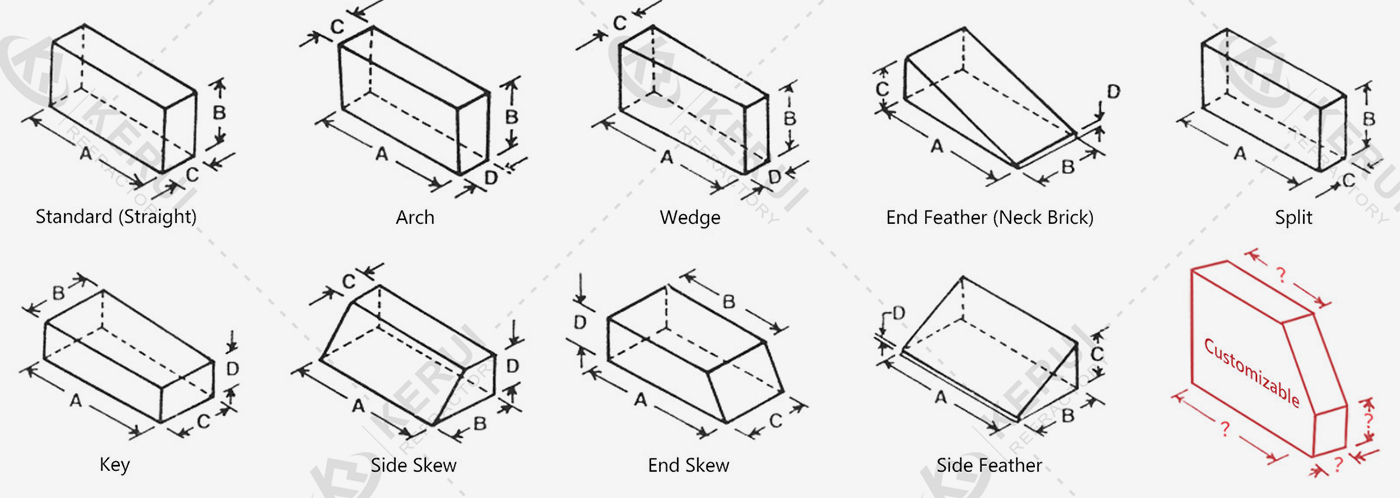

Customized Refractory Fire Bricks

Kerui Refractory factory can be customized all kinds of shaped bricks according to the customer’s request. Because we have own factory, and our own R&D team, technical team, production team. In addition, we also have a professional sales team and service team who are familiar with each market. So welcome to inquiry!

Applications Of Kerui Refractory Fire Bricks

Sintering Furnaces and Kilns

Sintering Furnaces and KilnsRefractory bricks are commonly used in the construction of sintering furnaces and kilns for ceramics, cement, lime, ore and other materials. They are able to withstand high temperatures for long periods of time.

玻璃窑炉

玻璃窑炉In the glass manufacturing industry, refractory bricks are used to construct glass furnaces that require high temperatures to melt the glass feedstock.

Steel Smelting

Steel SmeltingIn the steel industry, refractory bricks are used to build blast furnaces, converters, electric arc furnaces and other smelting equipment to withstand high temperatures and chemical attack.

Coal Gasifiers and Chemical Industry

Coal Gasifiers and Chemical IndustryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

Industrial High-temperature Furnace Body

Industrial High-temperature Furnace BodyRefractory bricks are often used to manufacture industrial furnace bodies, such as high-temperature smelting furnaces, incinerators, glass furnaces, steel furnaces, etc.

Coal gasifiers and chemical industry

Coal gasifiers and chemical industryRefractory bricks are also used in coal gasifiers, chemical reactors and other chemical industry applications because these furnaces need to withstand high temperatures and corrosive chemicals.

Production Process of Refractory Fire Bricks

我们有自己的工厂,拥有专业的技术团队和生产设备。

拥有全自动配料系统;20 台 400-1000 吨成型压机;2 * 168 米高温隧道窑;20000 平方米仓储车间。

确保产品质量,提高生产效率,为客户提供最满意的产品和服务。

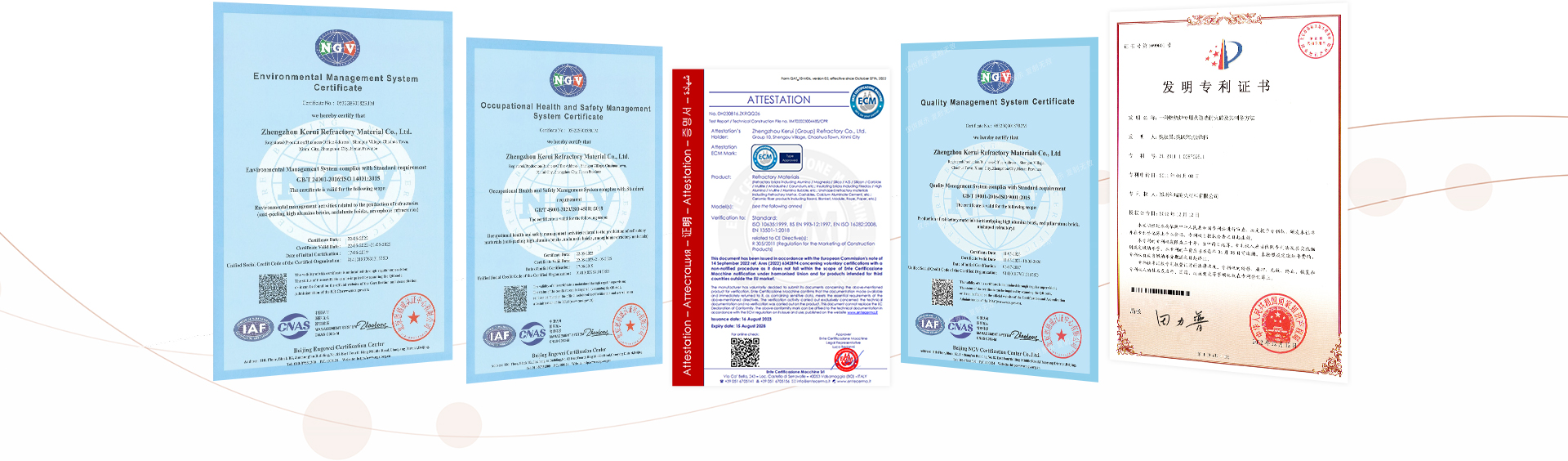

科瑞耐火材料证书

Kerui Group has a number of international certifications, such as, ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides,

Kerui’s products also have many domestic certificates, the quality is very guaranteed, and they have been unanimously recognized by customers at home and abroad.

科瑞耐火产品的包装与运输

The entire delivery process is tracked, and Kerui’s expert team solves specific project needs with the utmost professionalism.

If the customer’s project requires it, Kerui’s expert team will go to the customer’s country to provide face-to-face technical support.

科瑞耐火材料公司客户案例

除中国大陆外,科瑞耐火材料公司的产品已出口到世界五大洲的 50 多个国家和地区,包括亚洲、欧洲、美洲、非洲和大洋洲。

我们得到了世界各地客户的认可和好评,并不断收到客户的重复订单和推荐。

-

5各大洲

-

50+Countries

-

1700+成功案例

-

4500+客户