铬砖描述

高铬砖以氧化铬和氧化铝为主要原料,或加入少量氧化锆。经过高温烧制而成。氧化铬含量不低于 75%,氧化铬和氧化铝含量不低于 98% 的定型耐火制品。

Kerui Chrome Brick 的技术数据

| 项目 | 高铬氧化物砖 | 80 铬砖 | 70 铬砖 | 60 铬砖 | 50 铬砖 |

|---|---|---|---|---|---|

| Cr2O3、% | ≥93 | ≥80 | ≥70 | ≥60 | ≥50 |

| 体积密度,克/立方厘米 | ≥4.25 | ≥4.1 | ≥3.7 | ≥3.6 | ≥3.5 |

| 表观孔隙率,% | ≤16 | ≤16 | ≤16 | ≤15 | ≤16 |

| 冷压强度,兆帕 | ≥100 | ≥120 | ≥120 | ≥120 | ≥120 |

| 荷载软化温度,0.2MPa 0.6% | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

铬砖的优点

高铬砖具有优异的抗浸出性、常温抗压强度高、耐磨性优异、耐高温、抗热震性好等特点。

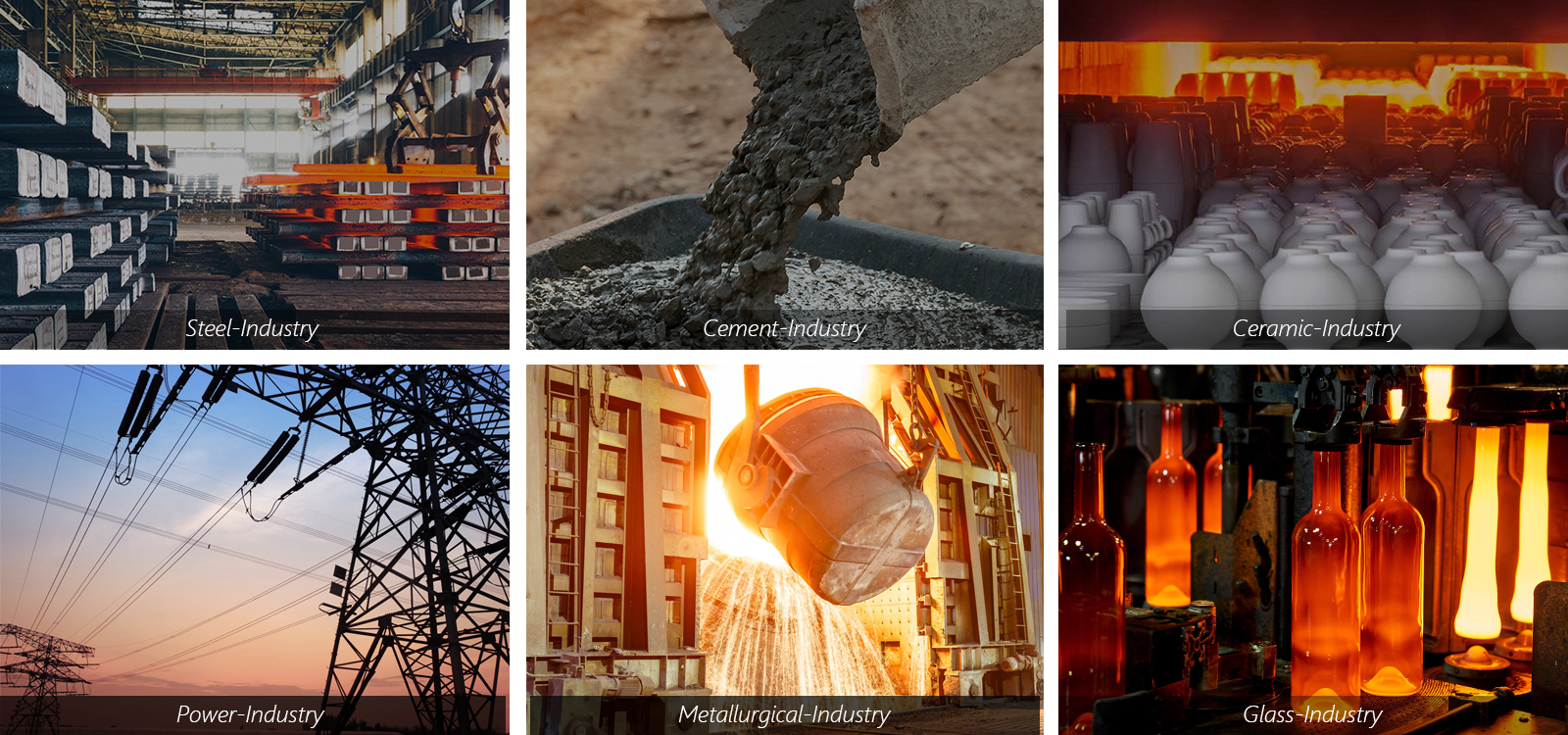

Application of High Chrome Bricks

高铬砖(Cr2O3≥90%)主要用于煤化工、化工窑、无碱玻璃纤维窑、垃圾焚烧炉、气化炉等关键部位。还可用于炭黑炉、铜冶炼炉、玻璃窑熔池、轧钢加热炉溜槽、卸钢平台等的内衬。