Argamassa refractária

- Al2O3%: 40-78

- Fe2O3%: 0,7-1,2

- Classificação Temperatura/℃: 1300-1600

- Subcarga de refractariedade/℃: 1320-1600

- Certificação: ISO9001/ISO14001/ISO45001/ISO50001

- Amostra: é possível testar a amostra

Descrição da argamassa refractária

A argamassa refractária, também conhecida como argamassa de alta temperatura, pode ser utilizada para resistir a ambientes de alta temperatura. É um tipo especial de argamassa concebido para aplicações a altas temperaturas onde a argamassa comum não consegue suportar o calor extremo. A argamassa refractária é composta por pó refratário, aglutinante e mistura com uma determinada proporção de partículas, vertida em água ou aglutinante líquido para fazer uma pasta. A argamassa refractária pode ser transformada em pó, e o tamanho mais pequeno pode ser inferior a 1 mm, e alguns são mesmo inferiores a 0,5 mm. A argamassa refractária tem um elevado desempenho de vedação e uma elevada resistência à corrosão. De acordo com os diferentes componentes, pode ser dividida em argamassa de argila, argamassa de alta alumina, argamassa de silicone, argamassa de magnésia, etc.

Ficha técnica da argamassa refractária Kerui

| Item/Grau | KR-1300 | KR-1400 | KR-1500 | KR-1600 | |

|---|---|---|---|---|---|

| Classificação Temperatura/℃ | 1300 | 1400 | 1500 | 1600 | |

| Composição química/% | ω (Al2O3)/% | 40 | 53 | 60 | 78 |

| ω (Fe2O3)/% | 1.2 | 1 | 0.9 | 0.7 | |

| Subcarga de refractariedade/℃ | 1320 | 1410 | 1550 | 1600 | |

Classificação das argamassas refractárias

Argamassa refractária de argila

A argamassa refractária de argila é feita de argila calcinada juntamente com matérias-primas e aditivos. O clínquer é o principal componente da argamassa refractária de argila, com um teor de cerca de 75%~80%. Como material para juntas, a argamassa refractária de argila é utilizada principalmente nas juntas e na reparação de corpos de fornos construídos com tijolos de argila, tais como altos-fornos, altos-fornos a quente, fornos de coque, fornos de imersão, permutadores de calor, caldeiras, etc.

Argamassa refractária de sílica

A argamassa refractária de sílica é uma argamassa refractária feita de pó de sílica, argila, aditivos e ligantes misturados numa determinada proporção de partículas. A argamassa de sílica tem as vantagens de resistência a ácidos, elevada resistência ao calor, baixa condutividade térmica e boa resistência de ligação. A argamassa refractária de sílica é utilizada principalmente na alvenaria e reparação de fornos industriais, tais como altos-fornos a quente, fornos de coque e fornos de vidro construídos com tijolos de sílica.

Argamassa refractária de alta alumina

A argamassa de alta alumina é feita de cimento de alta alumina e agregado de alta alumina, com teor de alumina acima de 60%. A refratariedade é superior a 1500 ℃. É misturado com água para formar uma pasta para colocar e colar produtos refractários moldados, tais como tijolos refractários. A nossa argamassa refractária de alta alumina é a melhor escolha para lareiras de alta temperatura, fornos, fornos, fornalhas e construção de chaminés.

Vantagens da argamassa refractária

Elevada força de ligação

A argamassa refractária com água pode formar uma forte ligação entre tijolos ou materiais refractários quando utilizada, o que pode formar uma estrutura forte e duradoura. Aumenta a estabilidade global e a capacidade de carga do revestimento refratário e assegura a integridade da instalação.

Elevado desempenho de vedação

Um elevado desempenho de vedação significa que a argamassa formará uma estrutura estanque entre os tijolos refractários ou as juntas para evitar fugas de gases ou líquidos. Este desempenho de vedação é fundamental para aplicações que exijam a contenção de gases de combustão, metais fundidos ou outras substâncias.

Excelente resistência à erosão por escória

As argamassas refractárias têm uma excelente resistência à erosão por escórias. A escória é o resíduo formado durante processos de alta temperatura, como a fundição de metais ou a combustão. A resistência da argamassa à escória garante a longevidade e a eficácia do revestimento refratário em tais ambientes.

Boa resistência à fragmentação

A argamassa refractária tem boas propriedades de descasque térmico. As argamassas refractárias resistem à fragmentação ou delaminação de tijolos ou superfícies refractárias, mesmo sob aquecimento e arrefecimento repetidos em fornos quentes. Esta propriedade é essencial para manter a integridade e a estabilidade do revestimento refratário ao longo do tempo.

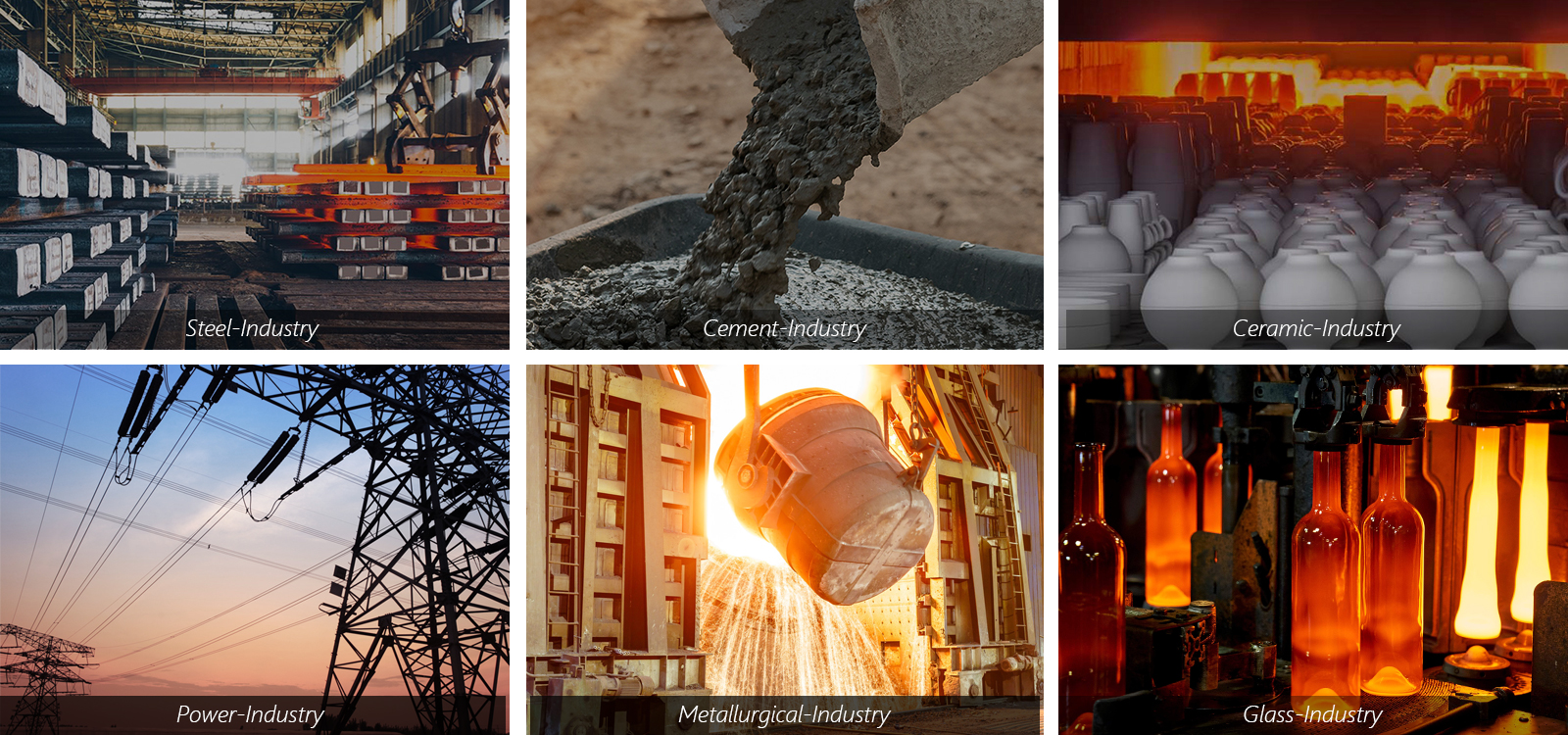

Aplicação da argamassa refractária

Indústria de metais não ferrosos

A argamassa refractária é utilizada na indústria de metais não ferrosos, incluindo a produção de alumínio, cobre e zinco. É utilizada para revestir fundições, conversores e outros equipamentos que possam suportar temperaturas elevadas e condições corrosivas.

Incineradores e gestão de resíduos

A argamassa refractária é utilizada em incineradores e instalações de gestão de resíduos para o revestimento de câmaras de combustão e sistemas de combustão. Proporciona isolamento térmico e resiste aos efeitos corrosivos dos gases de combustão e das cinzas.

Produção de energia

A argamassa refractária é utilizada para revestir caldeiras, incineradores e outros equipamentos de combustão em centrais eléctricas. Proporciona isolamento térmico e resiste às altas temperaturas e aos gases corrosivos gerados durante o processo de produção de energia.

Indústria de fundição

A argamassa refractária é utilizada em fundições para revestir cadinhos, moldes e outros equipamentos utilizados em processos de fundição de metais. Proporciona isolamento térmico e resistência ao metal fundido e à escória.

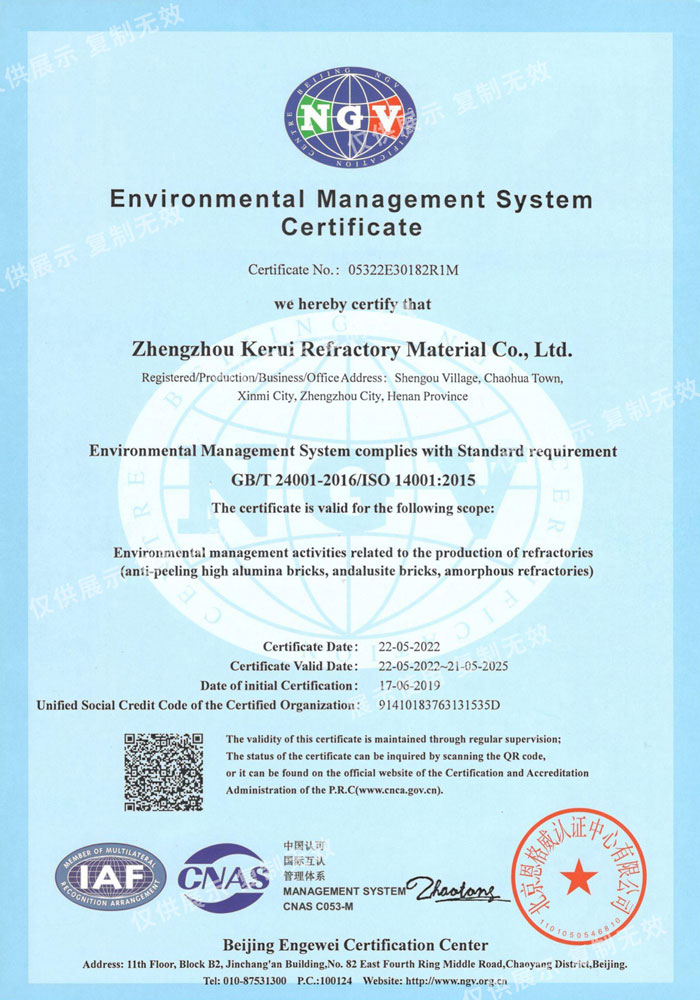

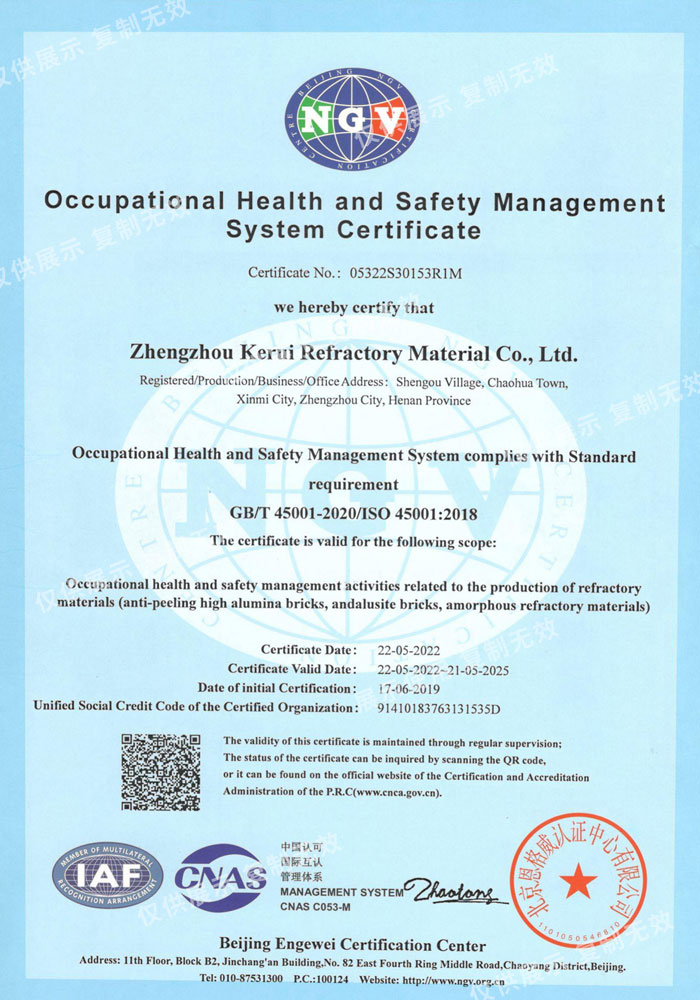

CERTIFICADOS DE REFRACTÁRIOS DE KERUI

O Grupo Kerui possui várias certificações internacionais, tais como, ISO9001/ISO14001/OHSAS18001/CE/SGS. Além disso, os produtos da Kerui também possuem muitos certificados nacionais, a qualidade é muito garantida e foram unanimemente reconhecidos pelos clientes no país e no exterior.

Laboratório de Refractários de Kerui

A Kerui possui um laboratório de inspeção de qualidade profissional. Forno de ensaio de fluência de reaquecimento/amaciamento de carga a alta temperatura; Banco de ensaio de resistência à compressão/flexão para materiais refractários; Plataforma de ensaio e inspeção da composição para materiais refractários; Laboratório de propriedades físicas/químicas para materiais refractários.

EMBALAGEM E ENVIO DE PRODUTOS REFRACTÁRIOS KERUI

Todo o processo de entrega é acompanhado e a equipa de especialistas da Kerui resolve as necessidades específicas do projeto com o máximo profissionalismo. Se o projeto do cliente o exigir, a equipa de especialistas da Kerui desloca-se ao país do cliente para prestar assistência técnica presencial.

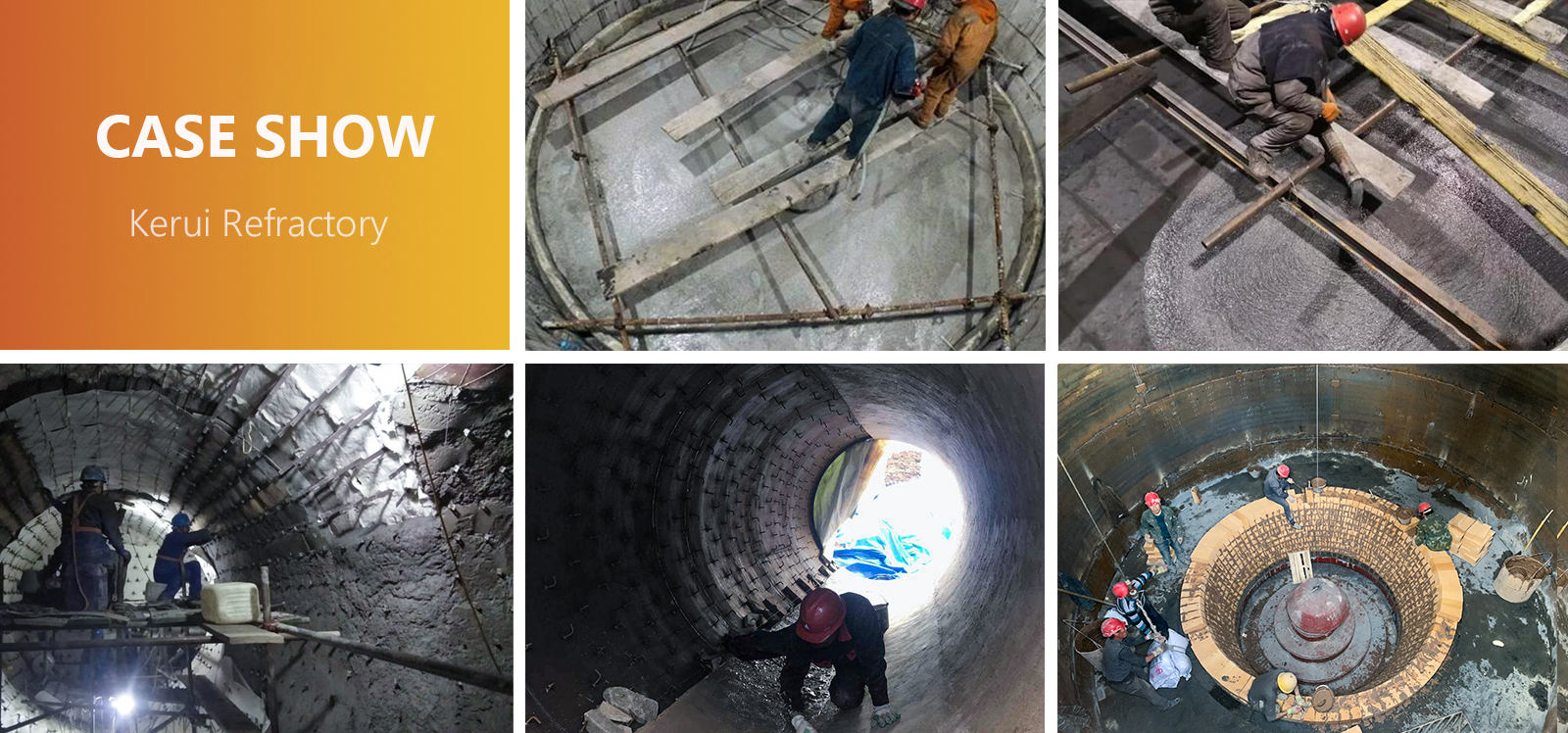

CASO DE CLIENTE DA KERUI REFRACTORY

Além da China continental, Kerui Refractory exportou produtos para mais de 50 países e regiões em 5 continentes em todo o mundo, incluindo Ásia, Europa, América, África e Oceania. Recebemos reconhecimento e elogios de clientes em todo o mundo, e estamos constantemente a receber pedidos de retorno e referências de clientes.